Manual Nursery Fork

bcp_604-9810_nursery fork-manualOverview

Cat® Nursery forks for Compact Wheel loaders, Compact Track Loaders, and Skid Steer Loaders are designed to allow pivoting one fork out for gained maneuverability and handling capabilities in nursery and landscaping applications. Fork tines can be configured with a manually adjusted fork or hydraulically side shifting fork to give greater flexibility when handling multiple or different sized root balls.

Specifications

| Overall Length | — |

| Overall Width | — |

| Weight | — |

Benefits & Features

Side Shifting Right Fork

Allows for greater control and maximizes proper fit when handling different sized root balls.

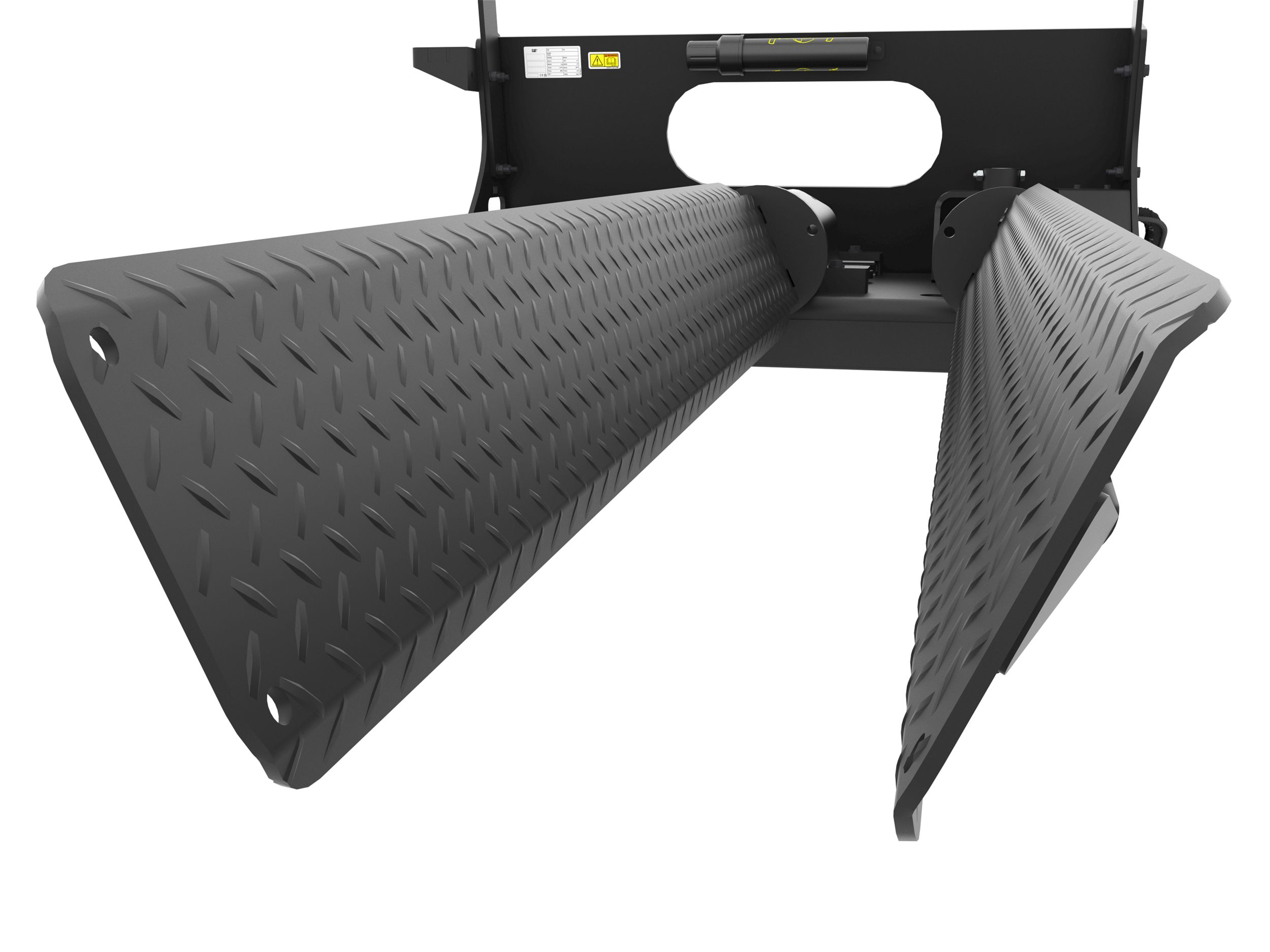

Pivoting Left Fork

Pivoting fork allows maximum opening to grasp larger root balls.

Diamond Tread Plate

Provides a secure grip on the load for maximum load retention. Fork angles at 25 degrees to closely match the standard angle on most root balls.

Specifications

| Overall Length | — |

| Overall Width | — |

| Weight | — |

| Overall Height | — |

| Usable Tine Length | — |

| Length Between Adjustments | 79 mm (3.1 in) |

| Number of Adjustments | 6 |

| Total Tine Movement | — |

| Angled Tine Opening Minimum at Tip | — |

| Angled Tine Opening Maximum at Tip | — |

| Parallel Tine Opening Minimum | — |

| Parallel Tine Opening Maximum | — |

| Maximum Root Ball Diameter | — |

| Maximum Lifting Capacity | — |

| Optimal Hydraulic Flow | 49-87 lpm (12-23 gpm) |

| Optimal Hydraulic Pressure | 170-241 bar (2500-3500 psi) |

| Interface Type | Skid Steer Coupler |

| Required Hydraulics | Standard Flow |

Benefits & Features

Side Shifting Right Fork

Allows for greater control and maximizes proper fit when handling different sized root balls.

Pivoting Left Fork

Pivoting fork allows maximum opening to grasp larger root balls.

Diamond Tread Plate

Provides a secure grip on the load for maximum load retention. Fork angles at 25 degrees to closely match the standard angle on most root balls.

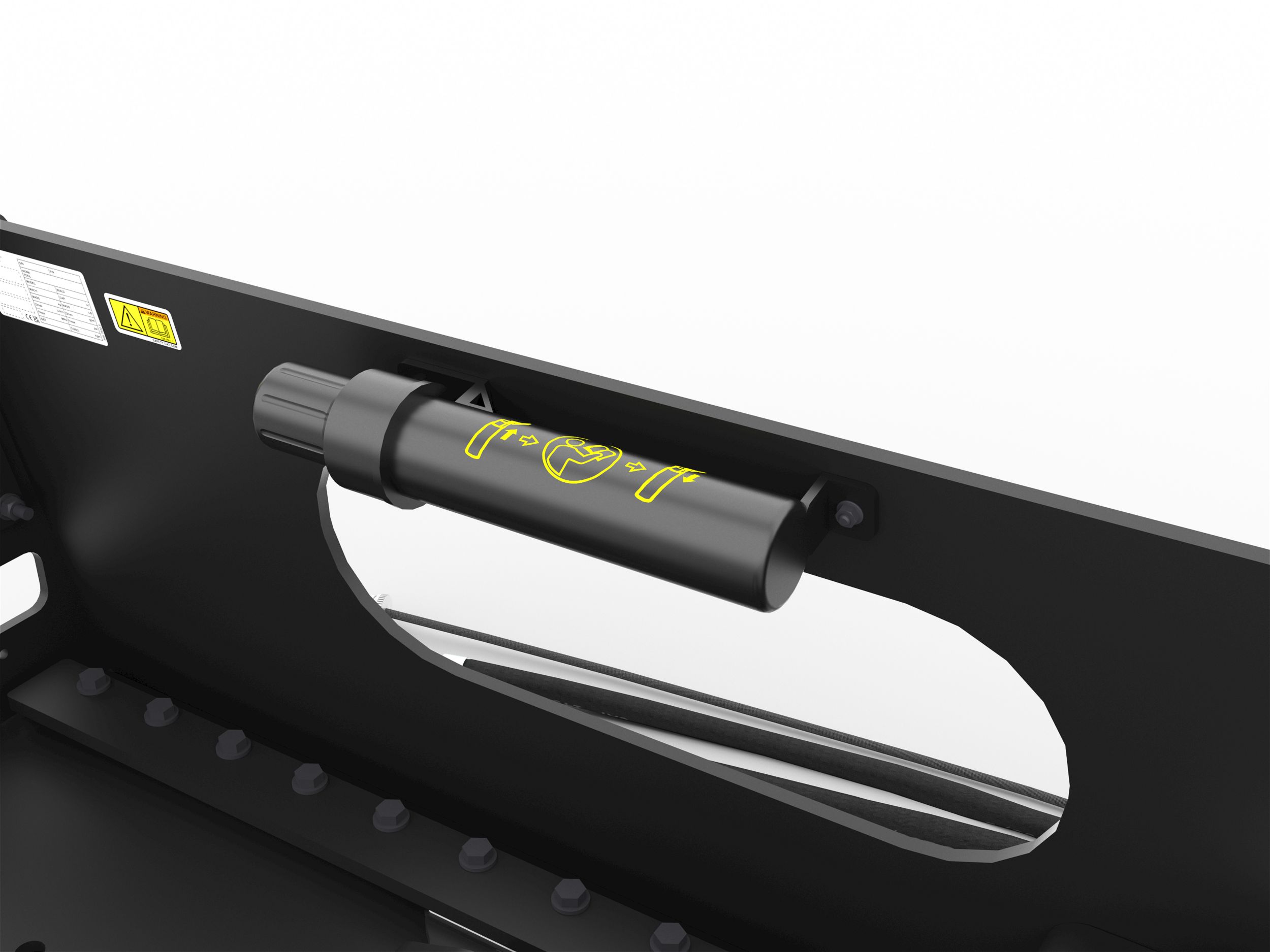

Grab Handle

Integrated grab handle allows a secure contact point upon entry/exit of the machine for the operator.

Serrated Step

Deeply serrated step provides secure footing for operators entering and exiting machines.

Operation Maintenance Manual Container

Tool mounted and sealed from the elements, this holder includes all the operation manuals and maintenance guides required for proper operation of the tool.

Data not available.