/

Attachments

/

Rotors

/

Rotors

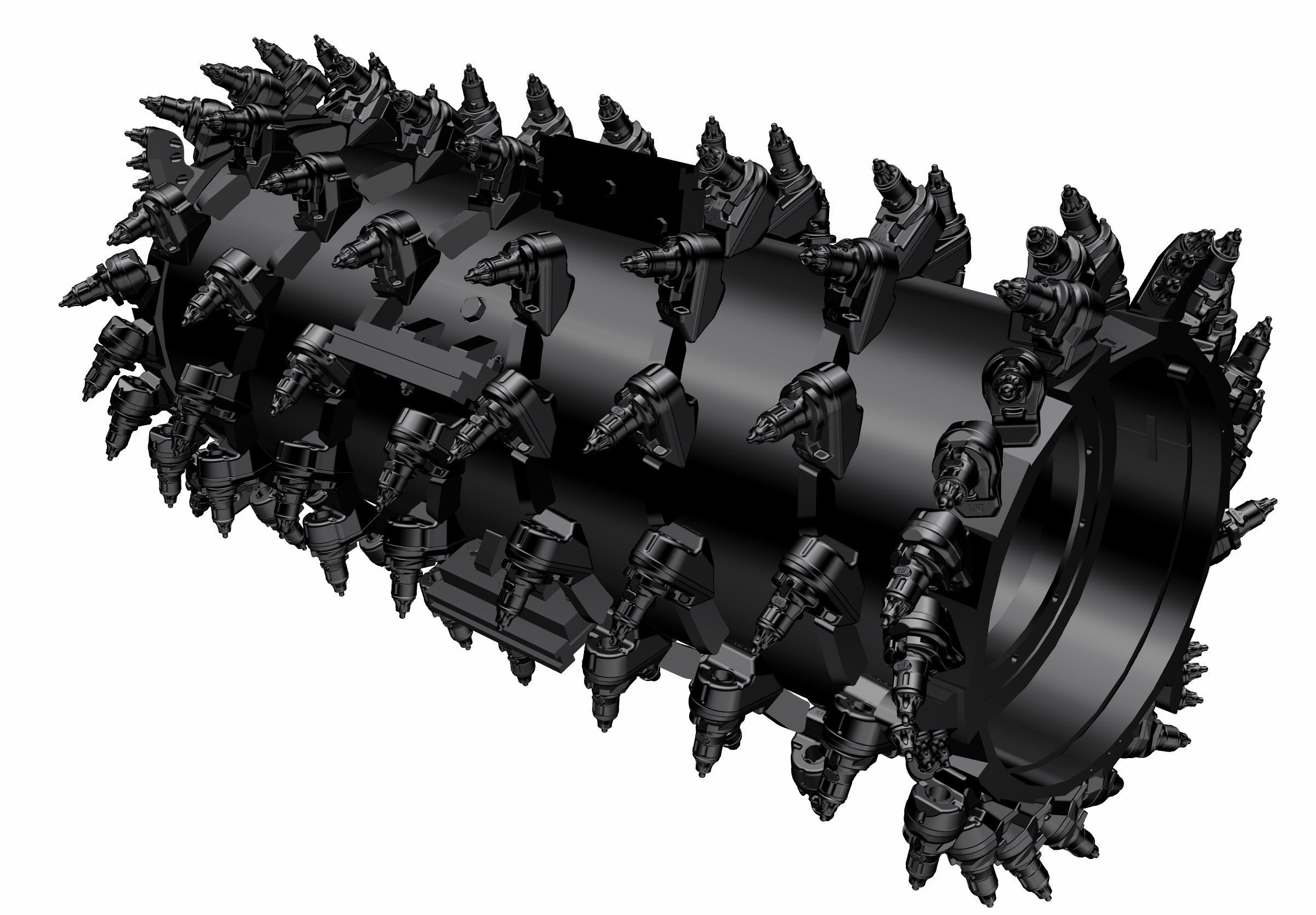

System K 2.0 m Milling Drum (25 mm spacing)

System K 2.0 m Milling Drum (25 mm spacing)Overview

The System K course milling rotor with 25 mm bit spacing is designed for surface removal or complete removal of road surfaces with a rougher finish at depths up to 330 mm (13 in). A durable, high-performance design with efficient material flow and an excellent cutting pattern maximizes milling production.

Specifications

Units:

| Milling Width | — |

| Tool Spacing | — |

| Drum Diameter at Tips | — |

Benefits & Features

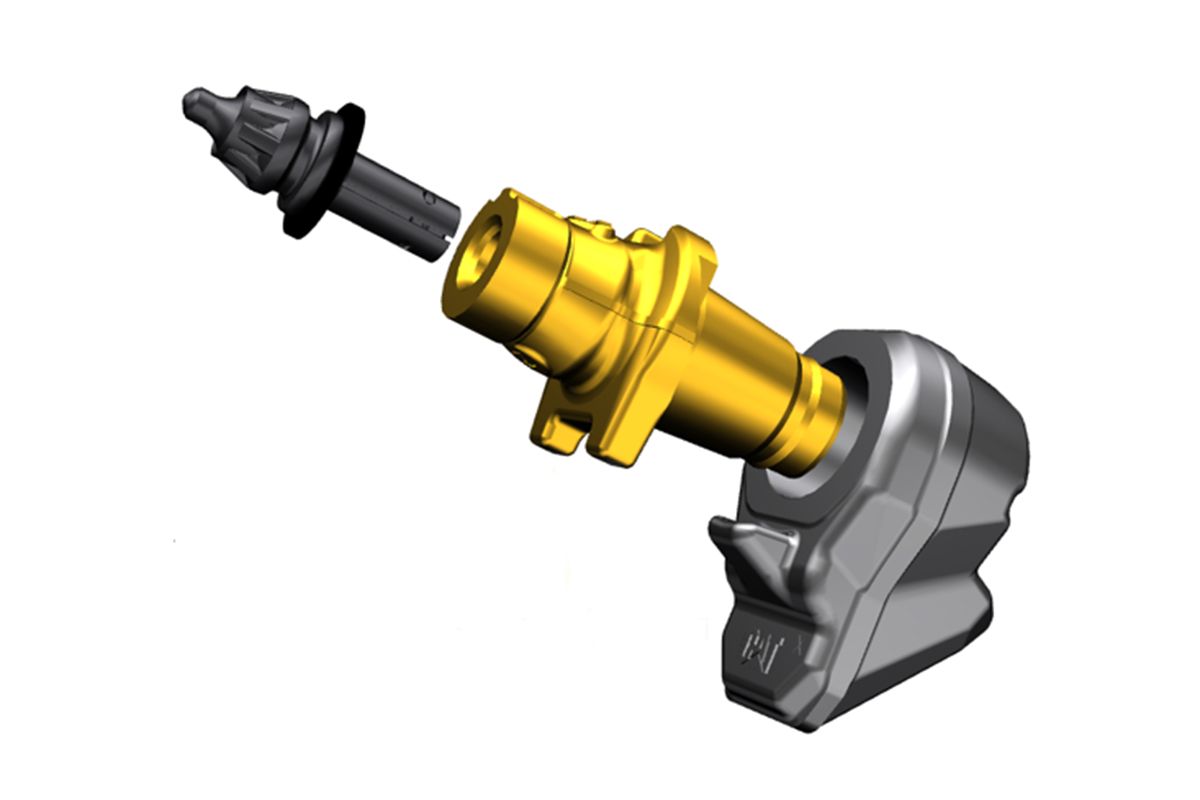

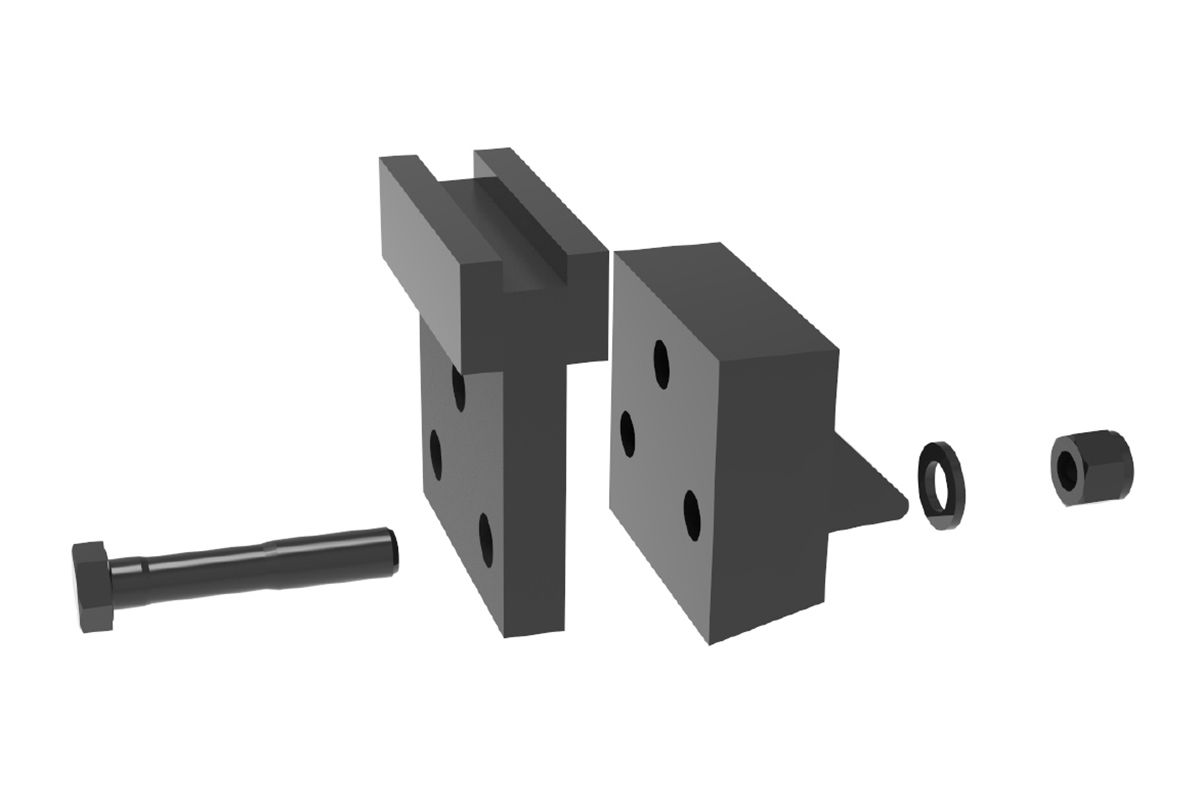

Toolholder Design

- The toolholder features multiple bit removal methods and a unique friction ring design to secure it to the rotor, yielding faster replacement and reduced downtime for rotor maintenance.

- A taper and friction ring design secures the toolholders to the rotor without a retaining pin, bolt or setscrew, speeding up replacement time by up to 50% and eliminating the need for fasteners or torqueing

- 20 mm wear collar is 66% longer than System G toolholders

- An anti-rotating toolholder design ensures proper position to prevent wear on the blocks and holders

- Water can penetrate through the toolholder radial access hole to aid tooth rotation for uniform bit wear

- Toolholders are available to accommodate bits with 20 mm, 22 mm and 25 mm shank size bits for various applications

Easy Bit Removal

- Multiple methods for easy bit removal:

- Radial access hole

- Chisel points

- Rear access through the block

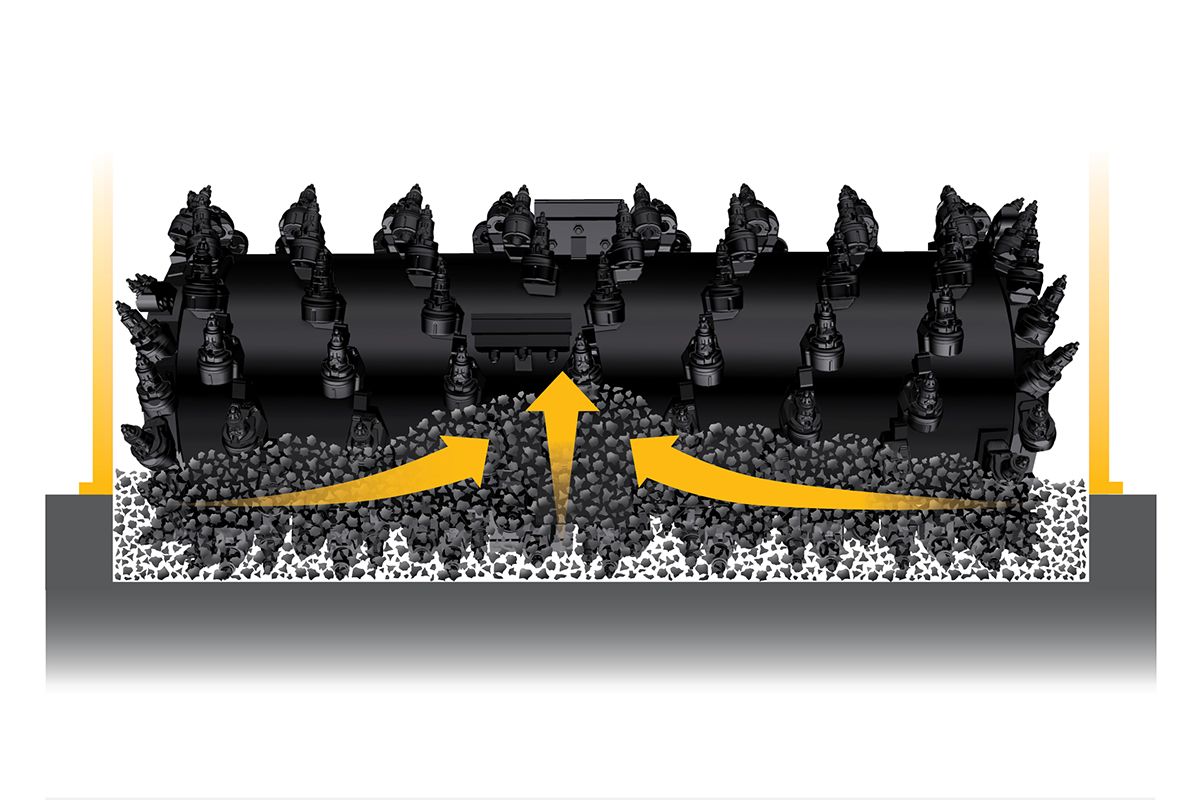

Efficient Material Flow

- An optimized spiral angle increases speed of material flow from the outside to the center for efficient material extraction

- Blocks are specifically designed for each side of the rotor and arranged for optimized cutting effort and efficient material flow

- Kicker paddles are dimensioned and tested to ensure maximum ejection of material from the center of the cutting chamber to the conveyor

- The rotor design reduces component wear by quickly removing material from the cutting chamber, reducing drag, improving overall machine efficiency and lowering fuel consumption

March 20, 2025

Specifications

Units:

| Milling Width | — |

| Tool Spacing | — |

| Drum Diameter at Tips | — |

| Milling Depth (max) | — |

| Number of Bits | 122 |

| PN# of Rotor Gp with Coolant and Tools (Factory Installed) | 582-7725 |

| PN# of Rotor Gp with Bits (Field installed) | 582-7727 |

Benefits & Features

Toolholder Design

- The toolholder features multiple bit removal methods and a unique friction ring design to secure it to the rotor, yielding faster replacement and reduced downtime for rotor maintenance.

- A taper and friction ring design secures the toolholders to the rotor without a retaining pin, bolt or setscrew, speeding up replacement time by up to 50% and eliminating the need for fasteners or torqueing

- 20 mm wear collar is 66% longer than System G toolholders

- An anti-rotating toolholder design ensures proper position to prevent wear on the blocks and holders

- Water can penetrate through the toolholder radial access hole to aid tooth rotation for uniform bit wear

- Toolholders are available to accommodate bits with 20 mm, 22 mm and 25 mm shank size bits for various applications

Easy Bit Removal

- Multiple methods for easy bit removal:

- Radial access hole

- Chisel points

- Rear access through the block

Efficient Material Flow

- An optimized spiral angle increases speed of material flow from the outside to the center for efficient material extraction

- Blocks are specifically designed for each side of the rotor and arranged for optimized cutting effort and efficient material flow

- Kicker paddles are dimensioned and tested to ensure maximum ejection of material from the center of the cutting chamber to the conveyor

- The rotor design reduces component wear by quickly removing material from the cutting chamber, reducing drag, improving overall machine efficiency and lowering fuel consumption

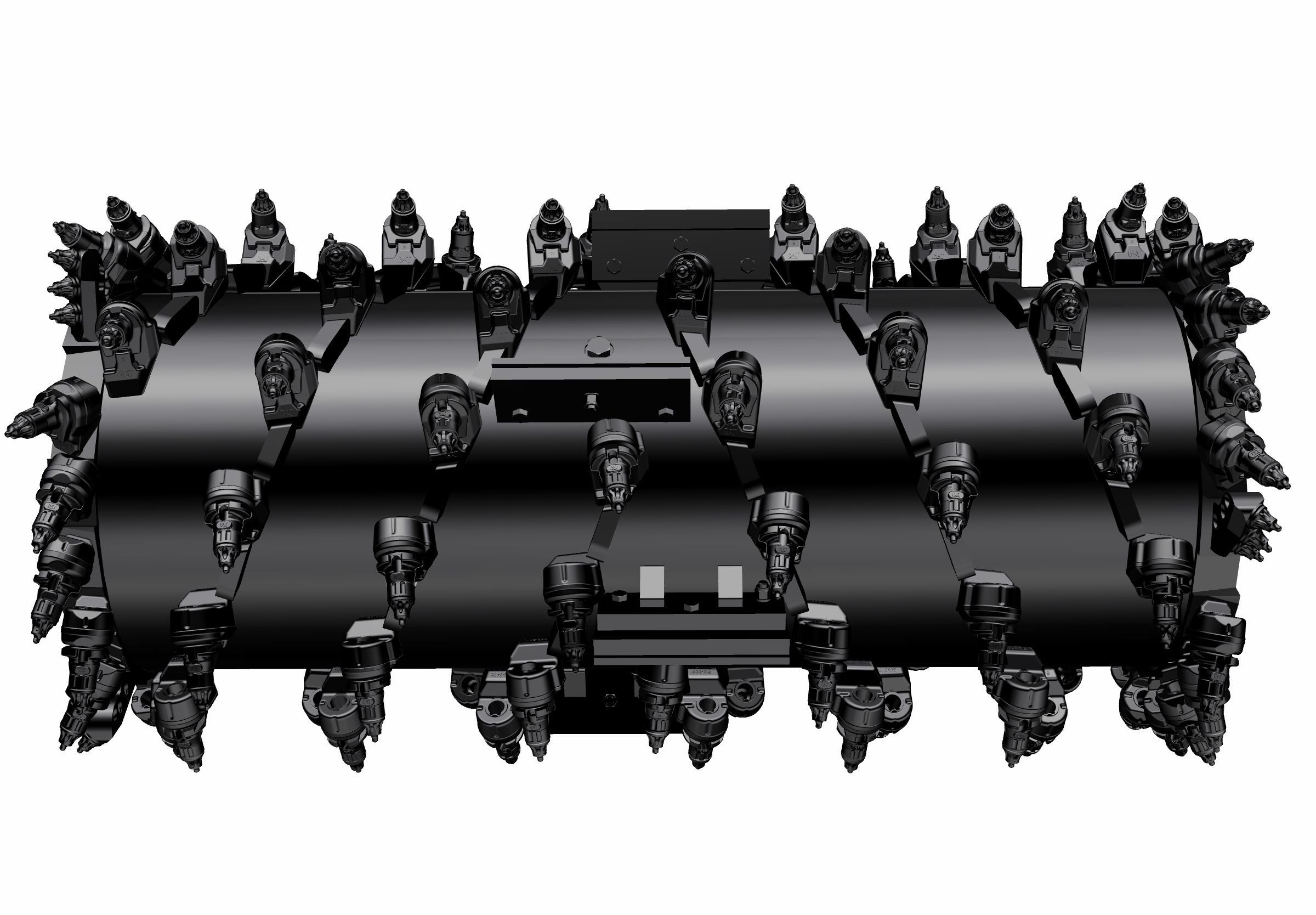

Durable Design

- Built to withstand demanding applications and extend rotor life

- Large heat-treated surface areas on the toolholder protect the base block from undesired wear

- Components are manufactured with abrasion-resistant, high-strength alloys to withstand the toughest applications

- High-strength components stand up to the demands of high-power applications

- Toolholder and base block designs are optimized to minimize stresses and provide lasting durability

Reversible Kicker Paddles

- Kicker paddles are reversible for extended life

Maintenance

- Maintaining bits and toolholders is key to achieving maximum productivity, and System K rotors are designed to simplify maintenance and get you back to work faster.

- Dual-retention toolholders eliminate the need for fasteners, reducing replacement time by up to 50%

- Bit removal can be done through multiple methods

- A variety of removal tools specifically for System K rotors help you replace bits and toolholders quickly

Data not available.