S45 Pin Grabber LCS 7-9 Ton Mini Excavators

bcp_576-1210_7-9 ton excavatorsOverview

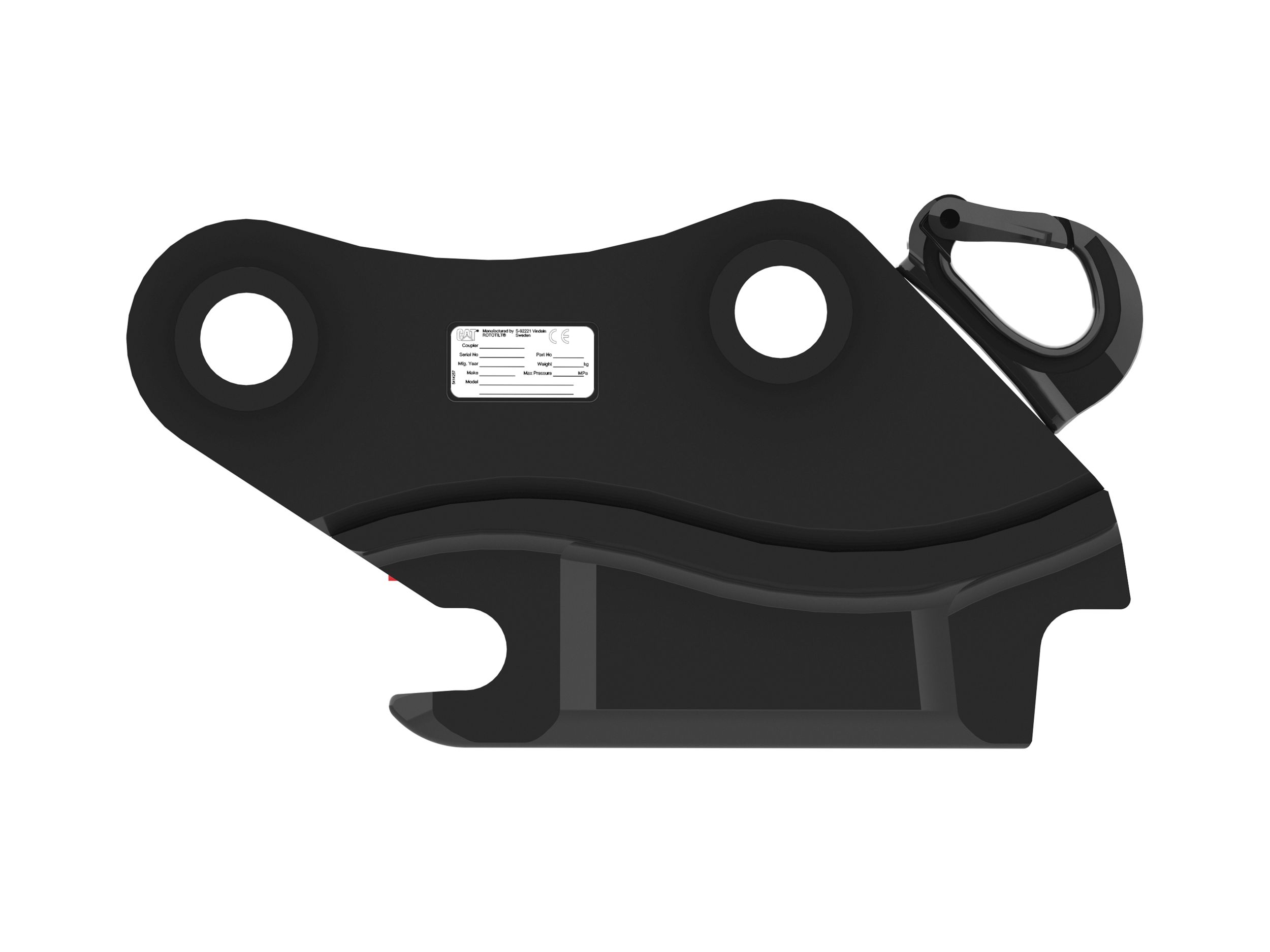

Cat® S Type Couplers for Mini Excavators are an optimal design for a dedicated quick coupler solution. Low offset, pin grabber ability, and a wedge type locking system ensures a tight fit, no attachment play during use. It also creates the solution to exchange work tools among different platforms and brands. In combination with the Tilt Rotate System that can be equipped with an S Type Coupler and the variety of different buckets offered, it provides a complete attachment solution for Mini Excavators. The coupler is designed with the highest safety standards and comes with a visible locking mechanism.

Specifications

| Weight | — |

| Lifting Hook Capacity | — |

| Width | — |

Benefits & Features

Hydraulic Cylinder Lock

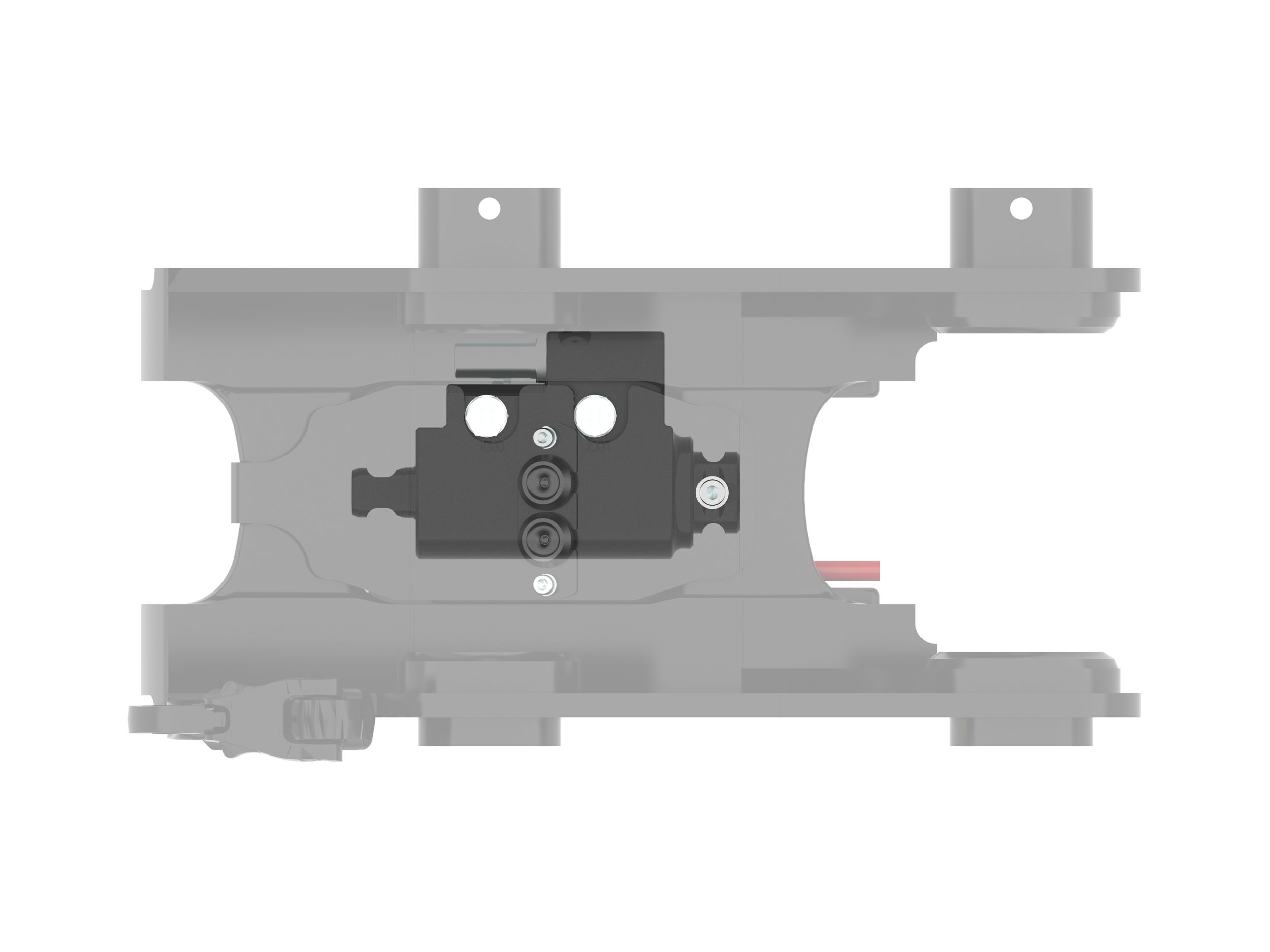

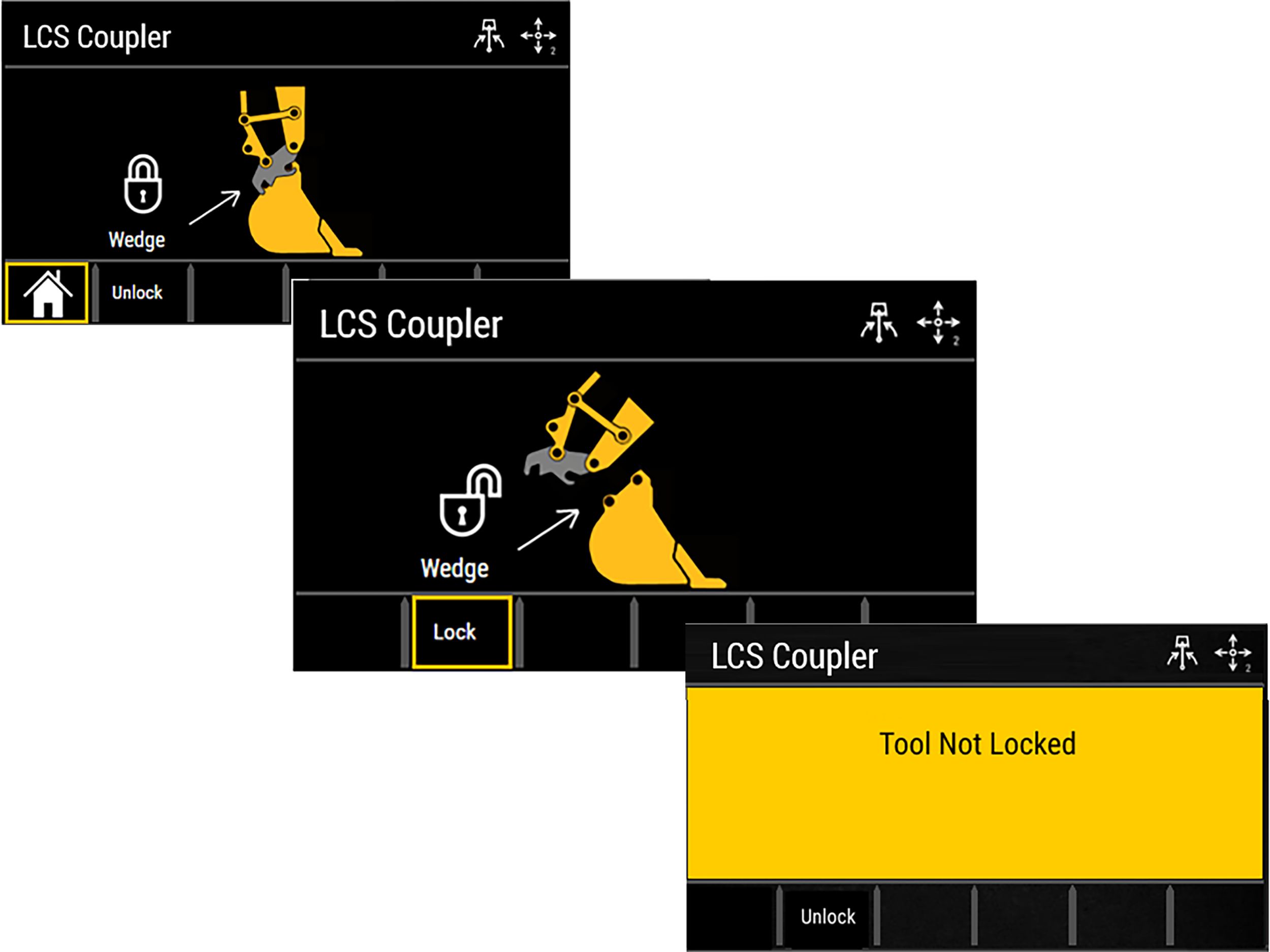

Hydraulic cylinder with check, relief and pressure control valve included. Locking Control System (LCS) incorporates an electronic position sensor integrated into the quick coupler hydraulic cylinder. This sensor provides precise and reliable input to an electronic processor mounted inside the quick coupler. This microprocessor provides digital communication to the Next Generation Mini Hydraulic Excavator machine's (ECM) by way of an electrical harness.

Locking Indicator

The visual verification rod allows the operator to visibly confirm, from the cab, that the coupler has successfully locked the attachment into place properly.

Lifting Hook

Integrated lifting hook allows the operator to switch tasks to lifting without changing tools or coupler.

Specifications

| Weight | — |

| Lifting Hook Capacity | — |

| Width | — |

| Overall Length | — |

| Overall Height | — |

| Pin Diameter | — |

| Machine Class | 7-9 Ton Mini Excavators |

| Interface Type | Pin On |

| Required Hydraulics | Dedicated Factory Installed |

| Maximum Operating Pressure | — |

| Coupler Type | S-45 Pin Grabber |

Benefits & Features

Hydraulic Cylinder Lock

Hydraulic cylinder with check, relief and pressure control valve included. Locking Control System (LCS) incorporates an electronic position sensor integrated into the quick coupler hydraulic cylinder. This sensor provides precise and reliable input to an electronic processor mounted inside the quick coupler. This microprocessor provides digital communication to the Next Generation Mini Hydraulic Excavator machine's (ECM) by way of an electrical harness.

Locking Indicator

The visual verification rod allows the operator to visibly confirm, from the cab, that the coupler has successfully locked the attachment into place properly.

Lifting Hook

Integrated lifting hook allows the operator to switch tasks to lifting without changing tools or coupler.

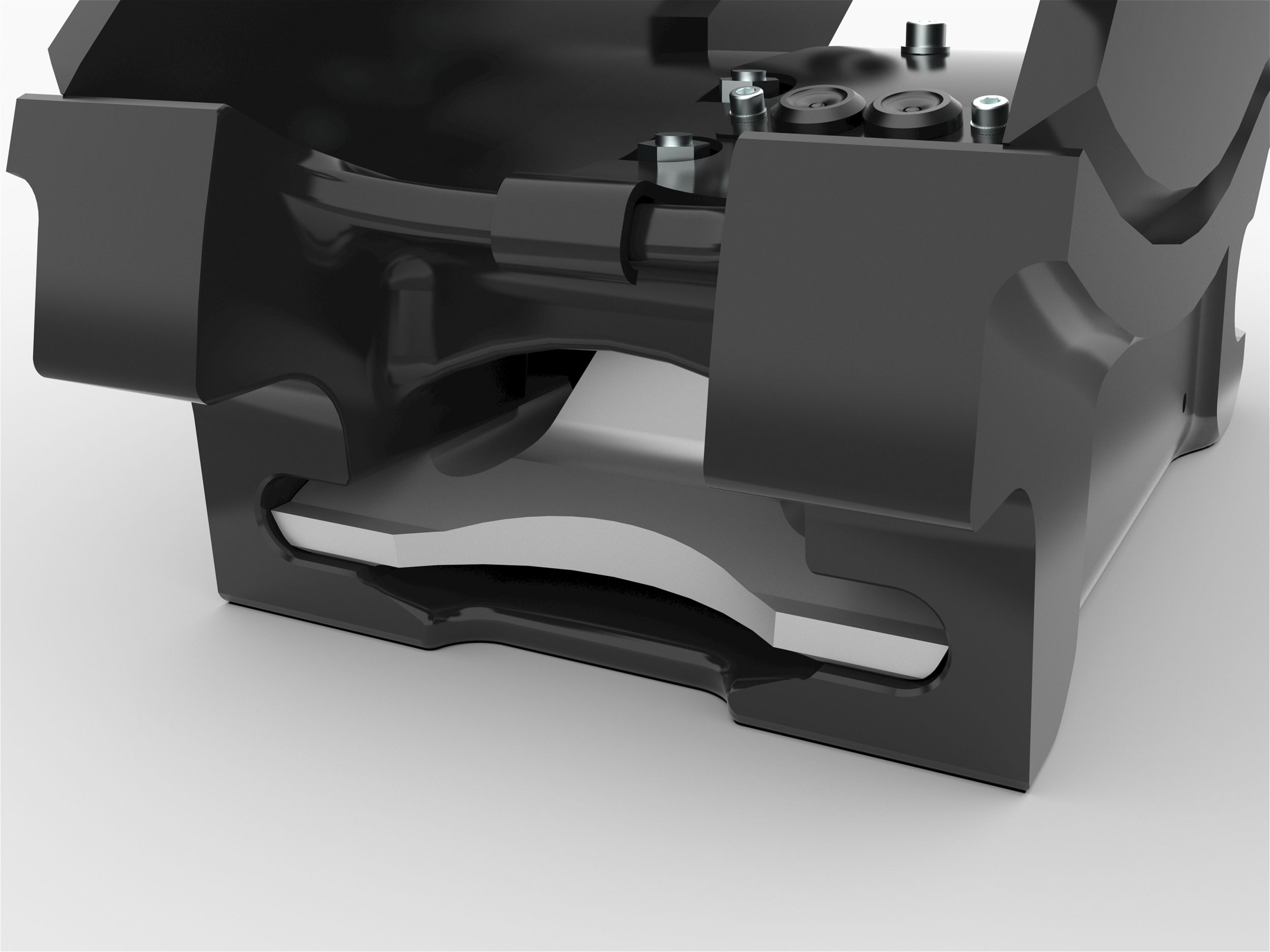

Low Profile/Build Height

Low build height quick coupler with minimal offset results in minimal break out force reduction.

Protected Components

All components integrated inside the coupler housing and protected against contaminants and potential force impact.

Wedge Type Locking Mechanism

Wedge type locking mechanism minimizes impact loading into the hydraulic cylinder.

Locking Control System

Locking Control System (LCS) incorporates cylinder positioning sensing and provides electrical feedback to the machine which requires Cat® software to display locking system status.

Data not available.