Overview

Cat® Tiltrotators help you get the job done faster with the quality you expect from Cat products. Integrated to your excavator, Tiltrotators are productive, easy-to-use, and add value to your operation. Tiltrotators are a versatile solution providing enhancements to your operation.

Specifications

Units:

| Machine Class | 14-19 |

| Interface Options: Top-Bottom | Pin-on High Flow / HCS65 |

| Rotation Speed | 7 seconds, per 1 full rotation |

Benefits & Features

Seamless Integration

- Tiltrotators connect to the machine’s HP2 circuit leaving the HP1 circuit for an additional attachment, ensuring smooth hydraulic flow to both

- Display function integrates into the machine’s monitor

- Positioning system connects to Cat GRADE with 3D

Up to 13% More Productivity

- Controls allow for simultaneous tilt, rotation, and machine movement

- Short height maintains consistent breakout force for digging

- Hydraulic quick connect changes attachments in seconds

- Do more work with less attachments and machines

Easy Operation

- Machine joysticks include Tiltrotator controls, preventing delay between operator command and action

- Oil-filled gear box keeps gears constantly lubricated, extending the life of the rotor

- Lubrication System has one grease point, which can be attached to the machine’s greasing

- Innovative Control System has four unique operator settings

June 6, 2025

Specifications

Units:

| Machine Class | 14-19 |

| Interface Options: Top-Bottom | Pin-on High Flow / HCS65 |

| Rotation Speed | 7 seconds, per 1 full rotation |

| Tilt Angle Range | 40° Left/Right |

| Maximum Bucket Capacity | — |

| Maximum Bucket Width | — |

| Optimal Hydraulic Flow | 111 L/min (29 gpm) |

| Maximum Operating Pressure | — |

| Tilting Torque | — |

| Turning Torque | — |

Benefits & Features

Seamless Integration

- Tiltrotators connect to the machine’s HP2 circuit leaving the HP1 circuit for an additional attachment, ensuring smooth hydraulic flow to both

- Display function integrates into the machine’s monitor

- Positioning system connects to Cat GRADE with 3D

Up to 13% More Productivity

- Controls allow for simultaneous tilt, rotation, and machine movement

- Short height maintains consistent breakout force for digging

- Hydraulic quick connect changes attachments in seconds

- Do more work with less attachments and machines

Easy Operation

- Machine joysticks include Tiltrotator controls, preventing delay between operator command and action

- Oil-filled gear box keeps gears constantly lubricated, extending the life of the rotor

- Lubrication System has one grease point, which can be attached to the machine’s greasing

- Innovative Control System has four unique operator settings

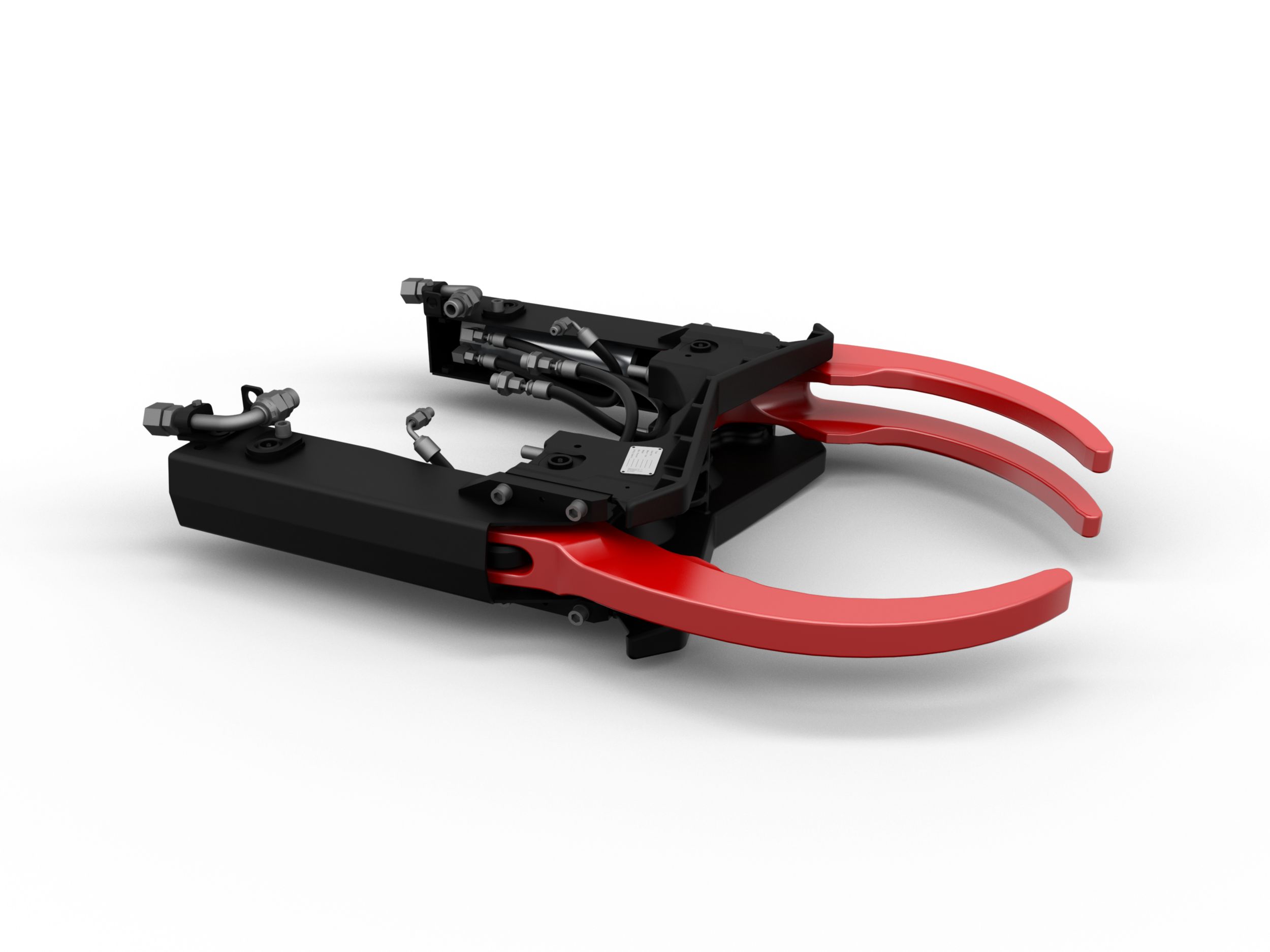

Enhanced Versatility

- 40⁰ left and right tilt, plus 360° rotation adds capability to fixed attachments

- Use grapple module without removing bottom attachment

- Mixed configurations enable use of multiple attachment interfaces

- Innovative Control system has settings for four unique operators

Stay Safe

- Curl to Unlock technology verifies the operator has the coupler or tiltrotator curled in the correct position before it is allowed to unlock during the process of switching attachments. This helps keep your attachments secure while working and connected to the coupler during the uncoupling process.

- Grapple module is faster and safer than people manually moving heavy objects

- Operator stays in cab while switching attachments

- Hydraulic quick connect does not require manual hose change

- Double acting tilt cylinders have built-in load holding valves in the event of pressure loss

Configuration Options

- Meet your usage and attachment interface needs with a variety of top and bottom configuration options for your tiltrotator depending on your preferred coupler system.

- Tiltrotators with a pin-on top are ideal when the tiltrotator is used regularly and compatible attachments are switched out on the bottom side.

- Options with a specific coupler interface on top are used with a standard coupler so the tiltrotator can be detached and larger or higher flow requirement attachments can be used with the standard coupler.

- Specific coupler interfaces may require attachments or brackets for attachments with that interface.

- The following are the current available interfaces for tiltrotators:

- Pin-on

- CW Dedicated

- S Type

- Hydraulic Connecting S Type

Data not available.