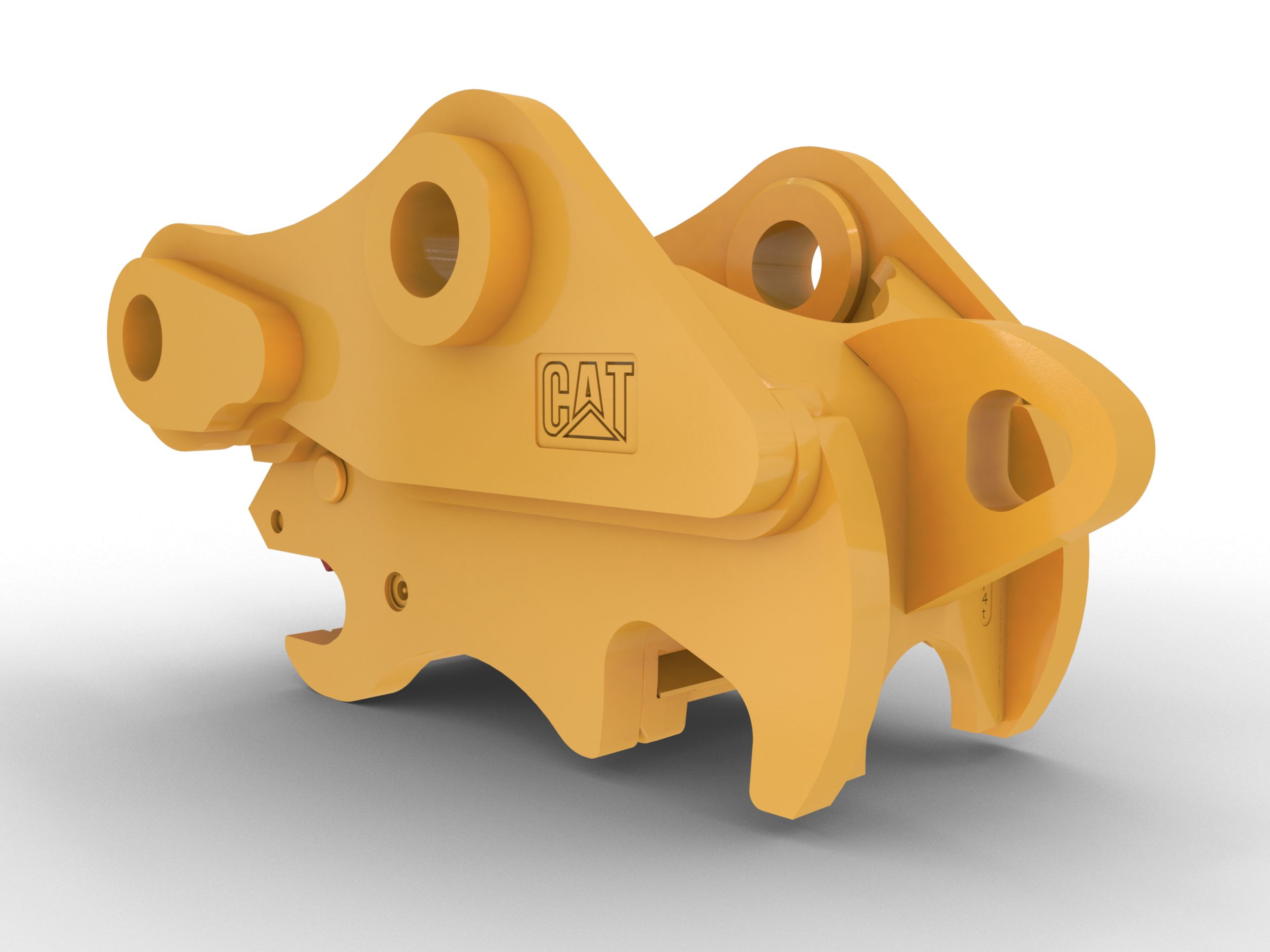

Pin Grabber Coupler (CB-Linkage): 455-3911

GCI_CPG_CB_LE_455-3911Overview

Cat® Pin Grabber Couplers bring another level of productivity and versatility to your operation. Add the ability to change attachments quickly and conveniently to your operation, while staying aligned to worldwide safety standards.

Specifications

Units:

| Minimum Carrier Weight | — |

| Maximum Carrier Weight | — |

| Weight | — |

Benefits & Features

Boost Productivity

- Get back to work faster with the capability to change attachments in seconds

- Attachments are shareable between similar sized excavators

- Couplers are weighted to handle big payloads, so you do not have to compromise on bucket size

- Do more with your equipment. Added versatility allows you to switch easily from digging, grading, material handling, compacting soil, breaking rocks, and more.

- Trenching widths available for certain coupler sizes:

- Saves backfill time and material

- Keeps the widest part of the coupler inside the digging width of 24- and 30-inch buckets

- Fully compatible with wider buckets and the same attachments as the standard models

- Pin Grabber Performance Buckets – recessed pins for an even further reduced tip radius

- Pick up buckets in reverse position to clean out square corners

Reliable Power and Strength

- Redundant locking system secures attachments:

- Primary wedge – Blocks pin movement like a deadbolt lock

- Secondary latch – Indicates to operator if coupler is either open or closed. Hinged to clamp the pin in place.

- Two spring-loaded arms – Assure secondary latch stays closed

- In the event you experience a loss of hydraulic pressure, redundant locking systems keep attachment in place

- Short coupler profile maintains tight tip radius, breakout force, and digging power

- Cast frame pieces made from abrasion-resistant steel

- Integrated, centered lift eye handles wide range of shackle, chain, and cable. Its interior shape keeps loads stable.

- Couplers without a lift eye are available in Japan to meet local lifting restrictions.

Top-of-mind Safety

- Visual and audible indicate to operator attachments are secure to the coupler.

- Greasing block provides a primary and easily accessible grease point.

- Operating procedures are simple and intuitive.

- Compliant with worldwide safety standards: ISO13031, EN474, and AS 4772:2008.

- Simplify on-the-job maintenance and improve reliability with the debris shield covering and protecting critical coupler components.

February 6, 2025

Specifications

Units:

| Minimum Carrier Weight | — |

| Maximum Carrier Weight | — |

| Weight | — |

| Attachment Pin Diameter - Stick (Front) | — |

| Attachment Pin Diameter - Link (Rear) | — |

| Pin Spread - Minimum | — |

| Pin Spread - Maximum | — |

| Lifting Eye Working Load Limit | — |

| Width - Machine Interface | — |

| Width - Attachment Interface | — |

Benefits & Features

Boost Productivity

- Get back to work faster with the capability to change attachments in seconds

- Attachments are shareable between similar sized excavators

- Couplers are weighted to handle big payloads, so you do not have to compromise on bucket size

- Do more with your equipment. Added versatility allows you to switch easily from digging, grading, material handling, compacting soil, breaking rocks, and more.

- Trenching widths available for certain coupler sizes:

- Saves backfill time and material

- Keeps the widest part of the coupler inside the digging width of 24- and 30-inch buckets

- Fully compatible with wider buckets and the same attachments as the standard models

- Pin Grabber Performance Buckets – recessed pins for an even further reduced tip radius

- Pick up buckets in reverse position to clean out square corners

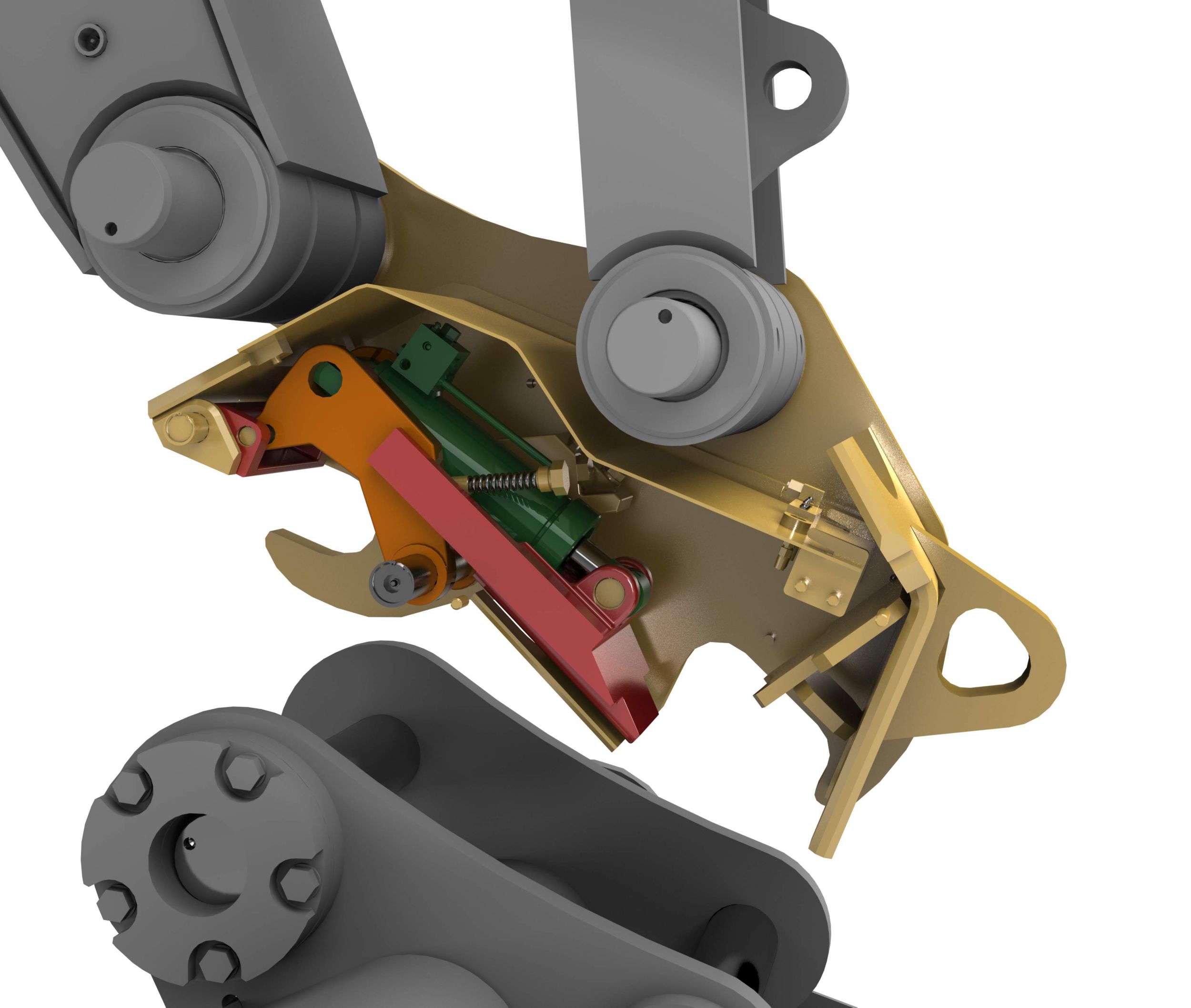

Reliable Power and Strength

- Redundant locking system secures attachments:

- Primary wedge – Blocks pin movement like a deadbolt lock

- Secondary latch – Indicates to operator if coupler is either open or closed. Hinged to clamp the pin in place.

- Two spring-loaded arms – Assure secondary latch stays closed

- In the event you experience a loss of hydraulic pressure, redundant locking systems keep attachment in place

- Short coupler profile maintains tight tip radius, breakout force, and digging power

- Cast frame pieces made from abrasion-resistant steel

- Integrated, centered lift eye handles wide range of shackle, chain, and cable. Its interior shape keeps loads stable.

- Couplers without a lift eye are available in Japan to meet local lifting restrictions.

Top-of-mind Safety

- Visual and audible indicate to operator attachments are secure to the coupler.

- Greasing block provides a primary and easily accessible grease point.

- Operating procedures are simple and intuitive.

- Compliant with worldwide safety standards: ISO13031, EN474, and AS 4772:2008.

- Simplify on-the-job maintenance and improve reliability with the debris shield covering and protecting critical coupler components.

Boost Efficiency and Productivity with Integrated Technologies

- Never waste time looking for your couplers again. Cat asset tracking is available on select Pin Grabber Couplers.

- Track your entire fleet of attachments and machines from one source. Couplers with asset tracking can be viewed in VisionLink®alongside Product Link™subscribed equipment.

- Keep your assets secure. Couplers with an asset tracker send an alert if they leave an easy-to-setup site boundary.

Data not available.