Overview

Cat® Hammers for Skid Steer Loaders, Compact Track Loaders, Mini Excavators and Backhoe Loaders are high performance breakers, designed for maximum performance on demolition, construction, and road work.

Specifications

| Operating Weight - With Tool | — |

| Energy Class | — |

| Machine Class | 7-10 Ton Mini Excavators, 415-450 Backhoe Loaders (no side shift) |

Benefits & Features

Application

Cat® B Hammers are suitable for use in a wide range of construction and light demolition applications - such as breaking concrete sidewalks and driveways, pavement, roads, masonry, site prep and landscaping, and breaking frozen ground for utility repairs.

Ergonomically Positioned Hydraulic Lines

Ergonomically positioned hydraulic lines are designed to optimize serviceability, are easily accessible and require no special tools. Housing has been positioned to protect against force and dirt during impact but allow for wrench access. Hydraulic lines and back head pressure can be checked and charged while breaker is mounted to machine, allowing quick monitoring of breaker's condition.

Gas Fired Design

Gas fired design delivers consistently high production over time making the breaker reliable in applications such as concrete, asphalt, rock and light trenching.

Specifications

| Operating Weight - With Tool | — |

| Energy Class | — |

| Machine Class | 7-10 Ton Mini Excavators, 415-450 Backhoe Loaders (no side shift) |

| Tool Shaft Diameter | — |

| Impact Frequency | 400-800 bpm |

| Minimum Operating Pressure | — |

| Minimum Carrier Weight | — |

| Optimal Hydraulic Flow | 60-100 lpm (15.9-26.4 gpm) |

| Overall Width | — |

| Overall Length | — |

| Overall Height | — |

| Height - Without Tool | — |

| Sound Level | 135 dB |

| Mounting Bracket Size | Extra Large |

Benefits & Features

Application

Cat® B Hammers are suitable for use in a wide range of construction and light demolition applications - such as breaking concrete sidewalks and driveways, pavement, roads, masonry, site prep and landscaping, and breaking frozen ground for utility repairs.

Ergonomically Positioned Hydraulic Lines

Ergonomically positioned hydraulic lines are designed to optimize serviceability, are easily accessible and require no special tools. Housing has been positioned to protect against force and dirt during impact but allow for wrench access. Hydraulic lines and back head pressure can be checked and charged while breaker is mounted to machine, allowing quick monitoring of breaker's condition.

Gas Fired Design

Gas fired design delivers consistently high production over time making the breaker reliable in applications such as concrete, asphalt, rock and light trenching.

Flat Top/Top-Mount Style

Flat top/top-mount style provides a larger work area and excellent operator visibility with a common footprint and hole pattern for optimum versatility. Top-mount style increases impact power by keeping breaker force and stick force in line. A top-mount bracket will transfer back significantly less recoil and bending stress into the end of the stick, resulting in reduced impact on machine structures. Full complement of mounting brackets is available to suite coupler or pin-on preference.

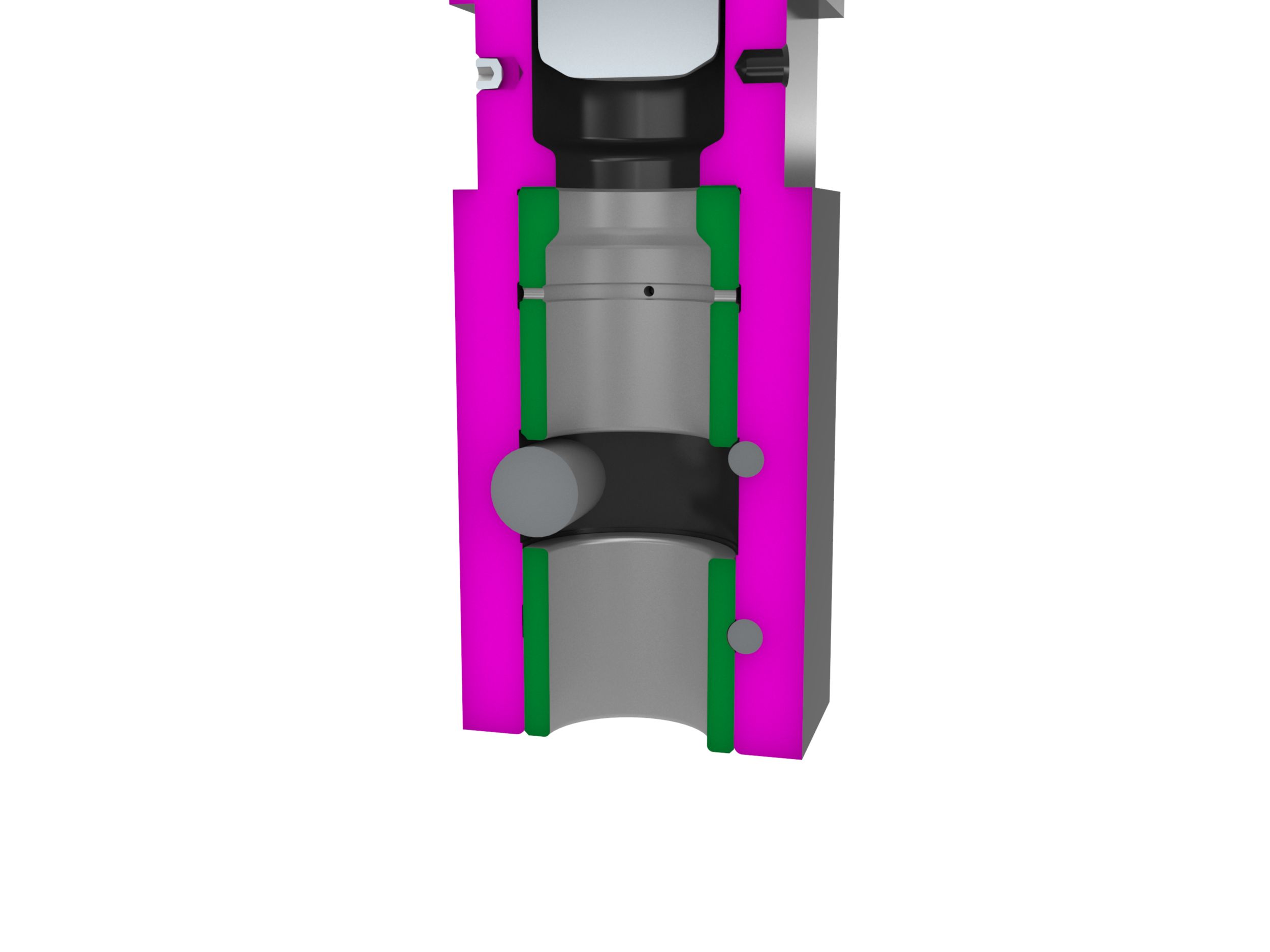

Slip Fit Bushings

Slip fit bushings are field replaceable and easy to maintain due to one locking pin, extending wear life and reducing owning and operating costs. Upper bushing rotates 360°, lower bushing has two positions and can be rotated 90°.

Included with Each B Series Hammer

- Every B Series Hammer comes with:

- Tool Kit w/Storage Box

- 2 Tools (1 x Conical and 1 x Transverse Chisel)

- Maintenance Kit

Data not available.