General Duty Bucket 1524 mm (60 in)Non-Current

GCI_267-1571_GD_Wamego/DB_1524 mm (60 in)Overview

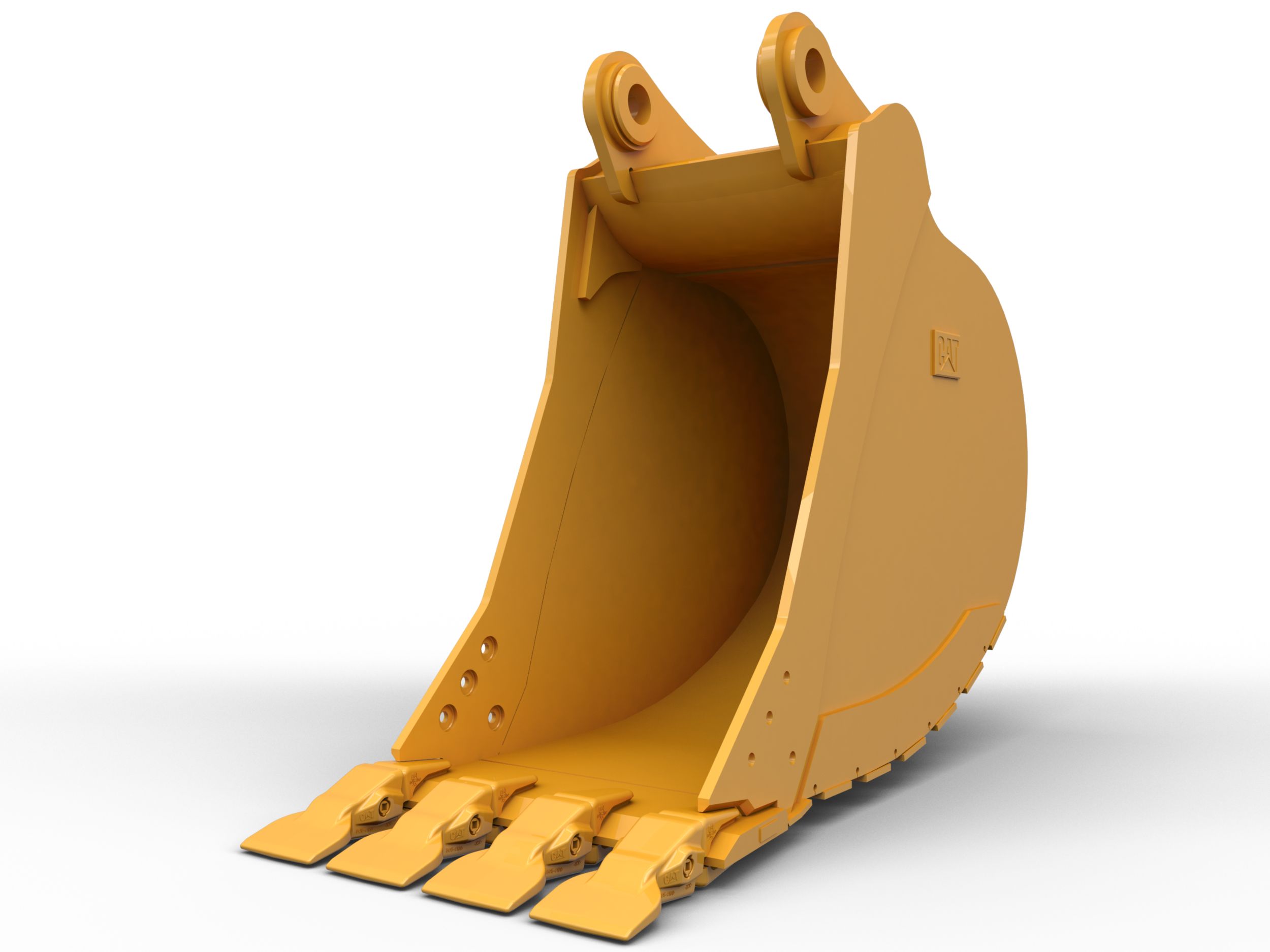

General Duty Bucket 1524 mm (60 in)

Specifications

Units:

| Width | — |

| Capacity | — |

| Weight | — |

Benefits & Features

High Performance

- Productivity is at its best when you pair your Cat machine with a Cat bucket, which we purpose-design to optimize the breakout force and power of the machine.

- The dual radius shell profile improves material flow into the bucket. The added heel clearance ensures the bottom of the bucket does not drag, reducing maintenance costs.

- Fuel consumption peaks during digging. Cat buckets are designed to cut through material quickly to enhance your machine's overall operating efficiency.

- Load more material in less time. Bucket shape and sidebars keep the most material in your bucket for every load.

Reliability and Durability

- Count on the structural integrity of your bucket long-term. The integrated hinge plate helps distribute force better than a weld-on hinge plate.

- Cat buckets are manufactured with high strength, abrasion-resistant steel, especially in excessive wear components.

- Protect the most important, high-wear areas of your bucket with Cat® Ground Engaging Tools (GET). Sidebar protectors and sidecutters help preserve the parts of the bucket that come into contact and pass through materials the most.

- Reduce maintenance costs by selecting the right GET for your bucket and application combination.

- Bucket tips are available in a variety of options to suit your specific application. Whether you need to leave a clean, level floor or dig hard, abrasive materials, there is a tip solution.

Versatility and Convenience with Couplers

- Managing multiple buckets and other attachments for a fleet is easier with a coupler system. Couplers allow machines of similar sizes to share and attachments can be changed out in seconds without leaving the safety of the cab.

- Buckets capable of being pinned directly to the machine are also compatible with Cat®Pin Grabber Couplers, except Pin Grabber Performance buckets. Pin Grabber Performance buckets have a recessed pin which optimizes breakout force resulting in faster cycle times for your bucket when using with a Cat Pin Grabber Coupler.

- The Cat Pin Grabber Coupler also gives the operator the ability to pick up a bucket in reverse position to clean out and square corners with ease.

- Ensure your attachments are secure with audible and visible cues from the coupler's secondary latch, always in the operator's line of sight.

- Cat Pin Grabber Couplers are compatible with 311-352 tracked excavators and all wheeled excavators. Trenching width couplers are also available.

- Attachments compatible with the CW Dedicated Coupler system use fixed quick coupler hinges. CW Dedicated Couplers feature a wedge-style locking system to keep attachments secure.

- CW Dedicated Couplers are available for all tracked and wheeled excavators.

April 22, 2025

Specifications

Units:

| Width | — |

| Capacity | — |

| Weight | — |

| Interface | Use as Pin-on or with Cat Pin Grabber Coupler |

| Adapter Quantity | 7 |

| Adapter Size | K80 |

| Edge Type | Straight |

Benefits & Features

High Performance

- Productivity is at its best when you pair your Cat machine with a Cat bucket, which we purpose-design to optimize the breakout force and power of the machine.

- The dual radius shell profile improves material flow into the bucket. The added heel clearance ensures the bottom of the bucket does not drag, reducing maintenance costs.

- Fuel consumption peaks during digging. Cat buckets are designed to cut through material quickly to enhance your machine's overall operating efficiency.

- Load more material in less time. Bucket shape and sidebars keep the most material in your bucket for every load.

Reliability and Durability

- Count on the structural integrity of your bucket long-term. The integrated hinge plate helps distribute force better than a weld-on hinge plate.

- Cat buckets are manufactured with high strength, abrasion-resistant steel, especially in excessive wear components.

- Protect the most important, high-wear areas of your bucket with Cat® Ground Engaging Tools (GET). Sidebar protectors and sidecutters help preserve the parts of the bucket that come into contact and pass through materials the most.

- Reduce maintenance costs by selecting the right GET for your bucket and application combination.

- Bucket tips are available in a variety of options to suit your specific application. Whether you need to leave a clean, level floor or dig hard, abrasive materials, there is a tip solution.

Versatility and Convenience with Couplers

- Managing multiple buckets and other attachments for a fleet is easier with a coupler system. Couplers allow machines of similar sizes to share and attachments can be changed out in seconds without leaving the safety of the cab.

- Buckets capable of being pinned directly to the machine are also compatible with Cat®Pin Grabber Couplers, except Pin Grabber Performance buckets. Pin Grabber Performance buckets have a recessed pin which optimizes breakout force resulting in faster cycle times for your bucket when using with a Cat Pin Grabber Coupler.

- The Cat Pin Grabber Coupler also gives the operator the ability to pick up a bucket in reverse position to clean out and square corners with ease.

- Ensure your attachments are secure with audible and visible cues from the coupler's secondary latch, always in the operator's line of sight.

- Cat Pin Grabber Couplers are compatible with 311-352 tracked excavators and all wheeled excavators. Trenching width couplers are also available.

- Attachments compatible with the CW Dedicated Coupler system use fixed quick coupler hinges. CW Dedicated Couplers feature a wedge-style locking system to keep attachments secure.

- CW Dedicated Couplers are available for all tracked and wheeled excavators.

Boost Efficiency and Productivity with Integrated Cat Connect Technologies

- Never waste time looking for your buckets again. Cat asset tracking is available on select buckets.

- Track your entire fleet of attachments and machines from one source. Buckets with asset tracking can be viewed within VisionLink® alongside Product Link ™subscribed equipment.

- Keep your assets secure. Buckets with an asset tracker send an alert if they leave an easy-to-setup site boundary.

General Duty – For Universal Loading and Material Moving

- With widths from 450-2600 mm (18-102 in.), and a wide range of capacities, General Duty buckets are a solution for any excavator size.

- General Duty buckets are best suited for materials such as dirt, loam, and fine gravel and where the tip life can exceed 800 hours.

- The addition of extra plates along the side, bottom, and base of General Duty buckets enable a longer life than Utility Duty buckets.

- Using a Leveling Edge or Wide Tip General Duty bucket will enable you to backfill a trench, create a level floor, or achieve a smooth finish for any job.

- You can pin General Duty buckets directly to your machine or use them with a Cat Pin Grabber Coupler or CW Dedicated Coupler.

Data not available.