Overview

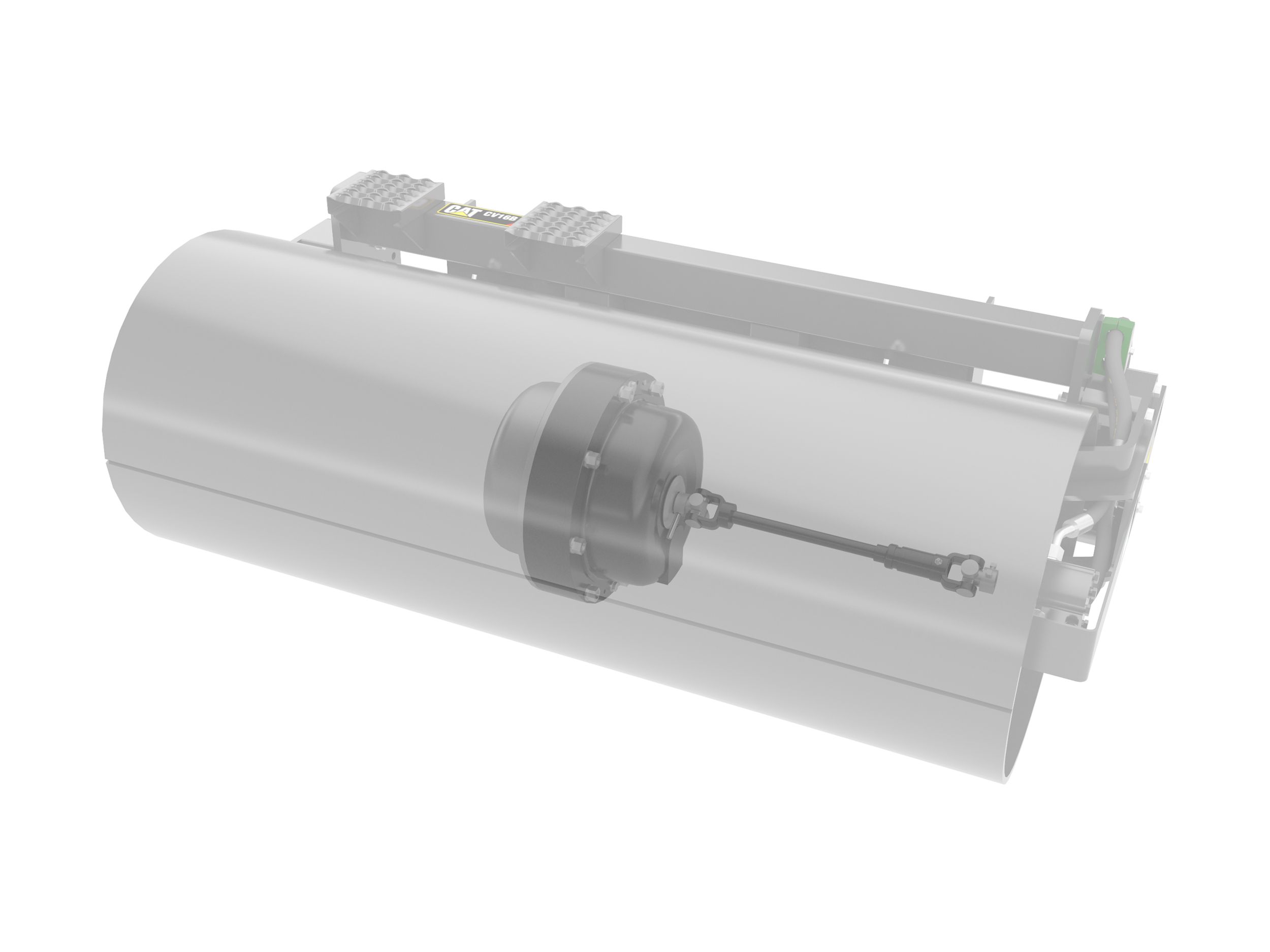

Cat® Vibratory Compactors are used for compacting soil, sand or gravel prior to pouring concrete or laying asphalt surfaces. They are also ideal for asphalt patch work. Their capabilities and lower investment and maintenance costs make them popular with pavers, general contractors and utility contractors in residential, commercial or industrial applications.

Specifications

| Drum Width | — |

| Weight | — |

| Required Hydraulics | Standard Flow |

Benefits & Features

Application

Used for compacting soil, sand or gravel prior to pouring concrete or laying asphalt surfaces. Also ideal for asphalt patch work.

Vibratory Pod Design

Caterpillar exclusive vibratory pod design delivers desired balance between frequency and amplitude to provide a superior matte finish.

Higher Compaction Forces

High compaction forces result in fewer passes for greater productivity.

Specifications

| Drum Width | — |

| Weight | — |

| Required Hydraulics | Standard Flow |

| Overall Width | — |

| Height | — |

| Drum Diameter | — |

| Optimal Hydraulic Flow | 42-86 L/min (11-23 gpm) |

| Optimal Hydraulic Pressure | 145-235 bar (2100-3400 psi) |

| Drum Frequency at Maximum Flow | 2,946 vibrations/minute |

| Drum Oscillation Tilt Range | ± 15 degrees |

| Dynamic Force | — |

| Amplitude | — |

| Motor Size | — |

| Drive Method | Gear Motor - Direct |

Benefits & Features

Application

Used for compacting soil, sand or gravel prior to pouring concrete or laying asphalt surfaces. Also ideal for asphalt patch work.

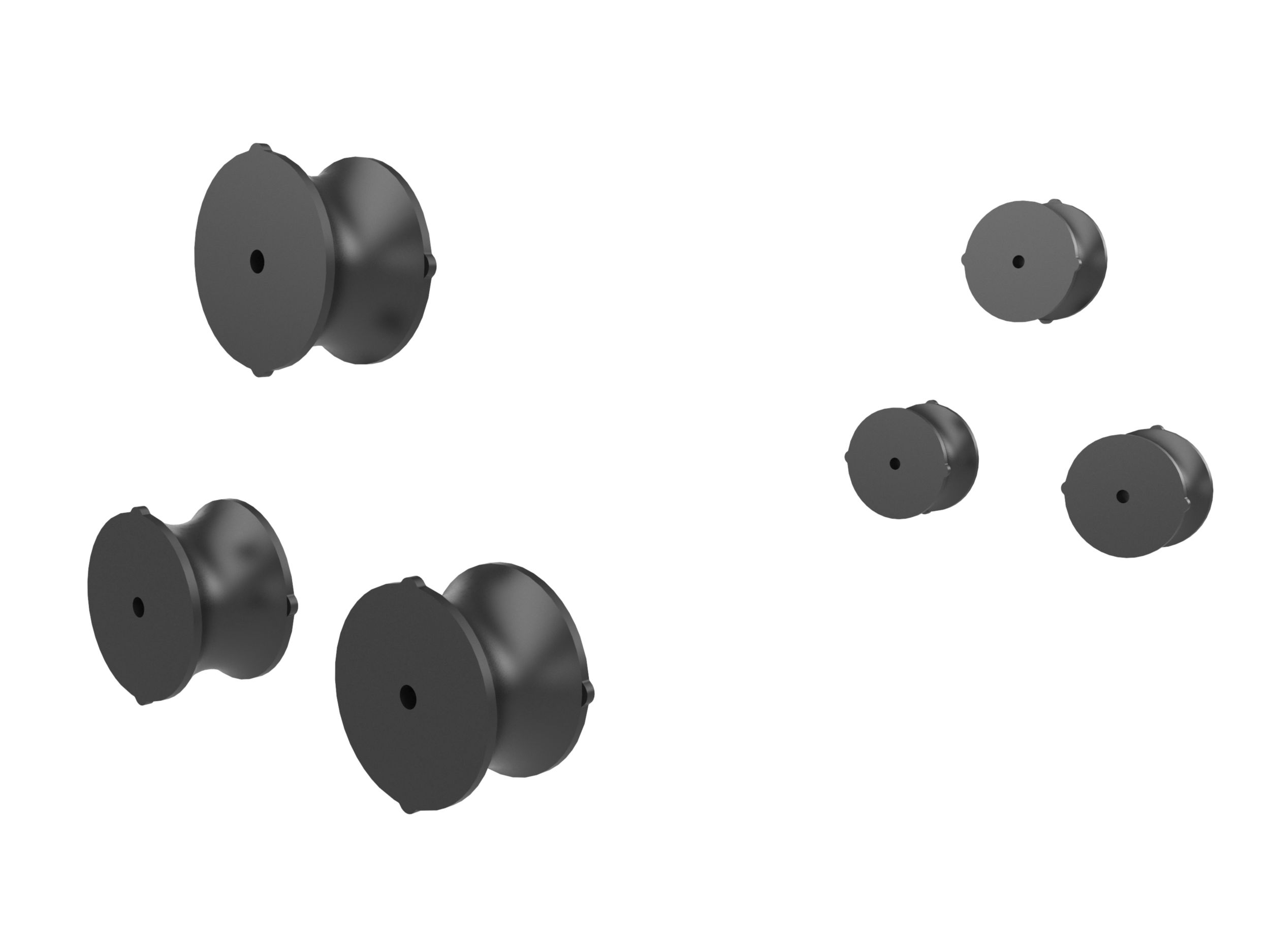

Vibratory Pod Design

Caterpillar exclusive vibratory pod design delivers desired balance between frequency and amplitude to provide a superior matte finish.

Higher Compaction Forces

High compaction forces result in fewer passes for greater productivity.

Replaceable Rubber Mounts

Replaceable rubber mounts isolate vibration and enhance vibratory capabilities.

High Strength Steel Drums

Durable high-strength steel drums are roll formed and finish welded for a smoother surface and longer life.

Pivoting Interface

Pivoting interface allows the drum to oscillate +/-15 degrees and follow the contour of the ground.

Spring-Loaded Scraper Bar

Spring-loaded dual direction non-metallic scraper bar maintains constant pressure on drum to prevent material build up. Non-metallic design minimizes noise.

Data not available.