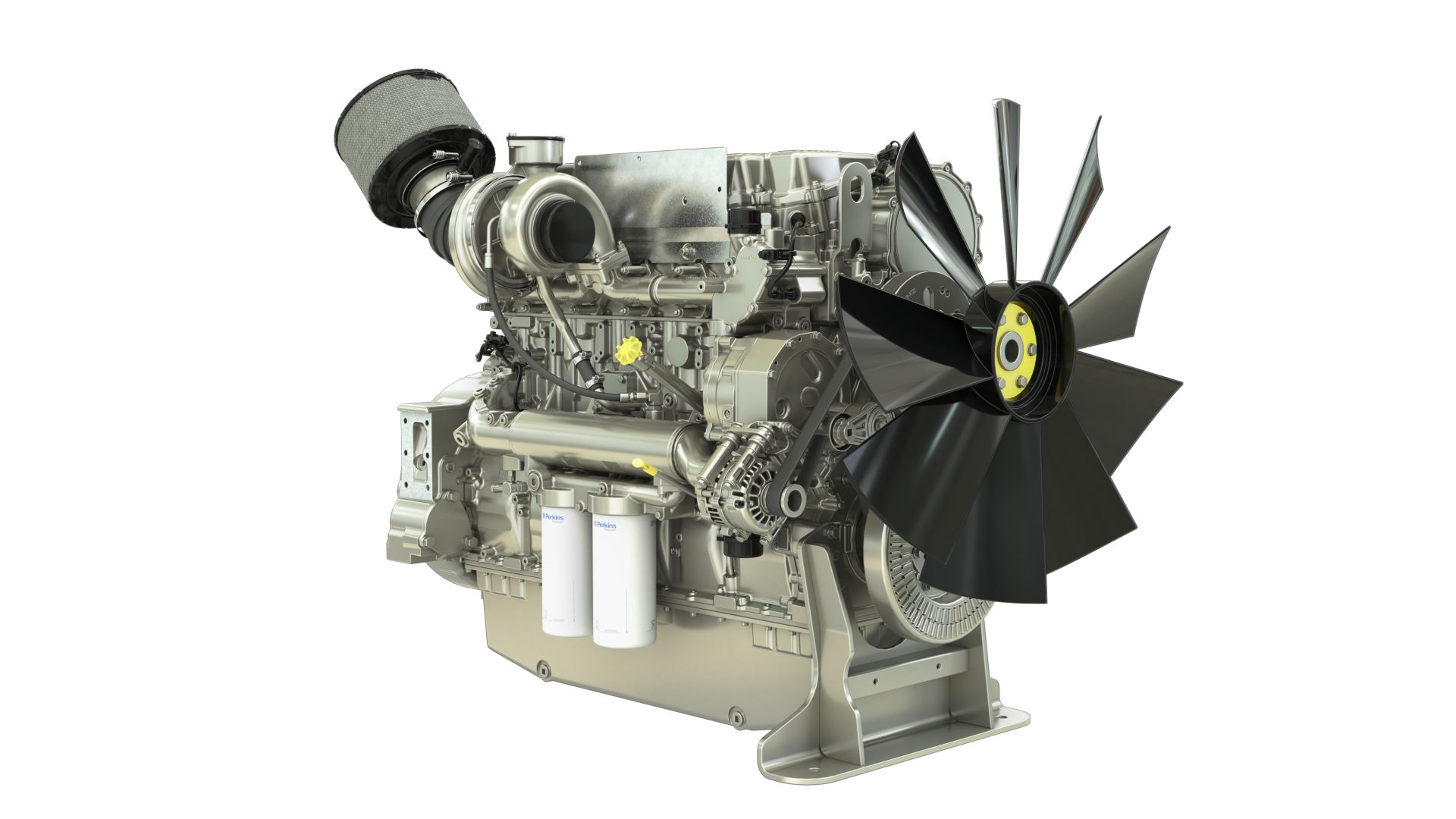

2806FA-E18TAG1 and TAG2

2806FA-E18TAG1 and TAG2Overview

The 2806FA owes its lineage to a long line of proven industrial and electric power engines that have performed for millions of hours all over the world. The 2806FA has been developed exclusively for India's latest emission standards. The SCR-only aftertreatment helps deliver cleaner emissions and excellent performance for years to come.

Specifications

| Gross Mechanical Output | 611 |

| Typical Electrical Output | N/A |

| Emissions | India CPCB IV+ |

Benefits & Features

Compact, clean and efficient power

Exceptional power to weight ratio and compact size give optimum power density for ease of installation and more cost effective transportation

Designed to provide excellent service access for ease of maintenanceEconomic power

Mechanically operated unit fuel injectors with electronic control combined with carefully matched turbocharging give excellent fuel atomsation and combustion with optimum economy

Reliable power

Developed and tested using the latest engineering techniques and finite element analysis for high reliability, low oil usage and low wear rates

High compression ratios ensure clean rapid starting in all conditions Perkins global product support is designed to enhance the customer experience of owning a Perkins powered machine. We deliver this through the quality of our distribution network, extensive global coverage and a range of Perkins supported OEM partnership options. So whether you are an end-user or an equipment manufacturer our engine expertise is essential to your successSpecifications

| Gross Mechanical Output | 611 |

| Typical Electrical Output | N/A |

| Rated Speed | 1500 rpm |

| Prime | N/A |

| Standby | N/A |

| Baseload | N/A |

| Prime | N/A |

| Standby | N/A |

| Baseload | N/A |

| Emissions | India CPCB IV+ |

| Number of Cylinders | 6 vertical inline |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Compression Ratio | 16.0:1 |

| Aspiration | Turbocharged aftercooled |

| Combustion System | Diesel Compression Ignition |

| Rotation from Flywheel End | Anti-clockwise |

| Cooling System | N/A |

| Aftertreatment | DOC+SCR+AMOX |

| Typical Alternator Efficiency | 95% |

| Switchable | No |

| Aftertreatment | Remote mounted |

| Cycle | N/A |

| Length | — |

| Width | — |

| Height | — |

| Dry Weight | — |

| Length | — |

| Width | — |

| Height | — |

| Weight | — |

| Note 1 | *Final dimensions dependent on selected options |

| Prime Power | Variable load. Unlimited hours usage with an average load of 70% of the published prime power rating. A 10% overload is available for 1 hour in every 12 hour of operation. |

| Standby Power | Variable load. Limited to 500 hours annual usage up to 300 hours of which may be continuous running. No overload is permitted. |

| Baseload | N/A |

Benefits & Features

Compact, clean and efficient power

Exceptional power to weight ratio and compact size give optimum power density for ease of installation and more cost effective transportation

Designed to provide excellent service access for ease of maintenanceEconomic power

Mechanically operated unit fuel injectors with electronic control combined with carefully matched turbocharging give excellent fuel atomsation and combustion with optimum economy

Reliable power

Developed and tested using the latest engineering techniques and finite element analysis for high reliability, low oil usage and low wear rates

High compression ratios ensure clean rapid starting in all conditions Perkins global product support is designed to enhance the customer experience of owning a Perkins powered machine. We deliver this through the quality of our distribution network, extensive global coverage and a range of Perkins supported OEM partnership options. So whether you are an end-user or an equipment manufacturer our engine expertise is essential to your successProduct support

Perkins actively pursues product support excellence by ensuring our distribution network invest in their territory � strengthening relationships and providing more value to you, our customer

Through an experienced global network of distributors and dealers, fully trained engine experts deliver total service support around the clock, 365 days a year. They have a comprehensive suite of web based tools at their fingertips covering technical information, parts identification and ordering systems, all dedicated to maximising the productivity of your engine Throughout the entire life of a Perkins engine, we provide access to genuine OE specification parts and service. We give 100% reassurance that you receive the very best in terms of quality for lowest possible cost .. wherever your Perkins powered machine is operating in the worldData not available.

Standard Equipment

- Air inlet system

- Mounted air filter

- Cooling system

- Gear-driven circulating pump

- Mounted belt-driven pusher fan

- System designed for ambients up to 55�C (131�F)

- Electrical equipment

- 3 level engine protection system

- 24 volt starter motor and 24 volt 85 amp alternator with DC output

- ECM mounted on engine with wiring looms and sensors

- Flywheels and flywheel housing

- High inertia flywheel to SAE J620 size 14

- SAE No. 1 flywheel housing

- Fuel system

- Governing to ISO 8528-5 class G3 with isochronous capability

- Mechanically actuated electronically controlled unit fuel injectors with full authority electronic control

- Replaceable spin on fuel filter elements with primary filter/water separator

- Mountings

- Front engine mounting bracket

- Oil system

- Full-flow replaceable filter

- Oil cooler and filter

- Wet sump with filler and dipstick

- Optional equipment

- CAM and crank speed sensors

- Temperature and pressure sensors for gauges

- Starter provided. Facility for second starter