Overview

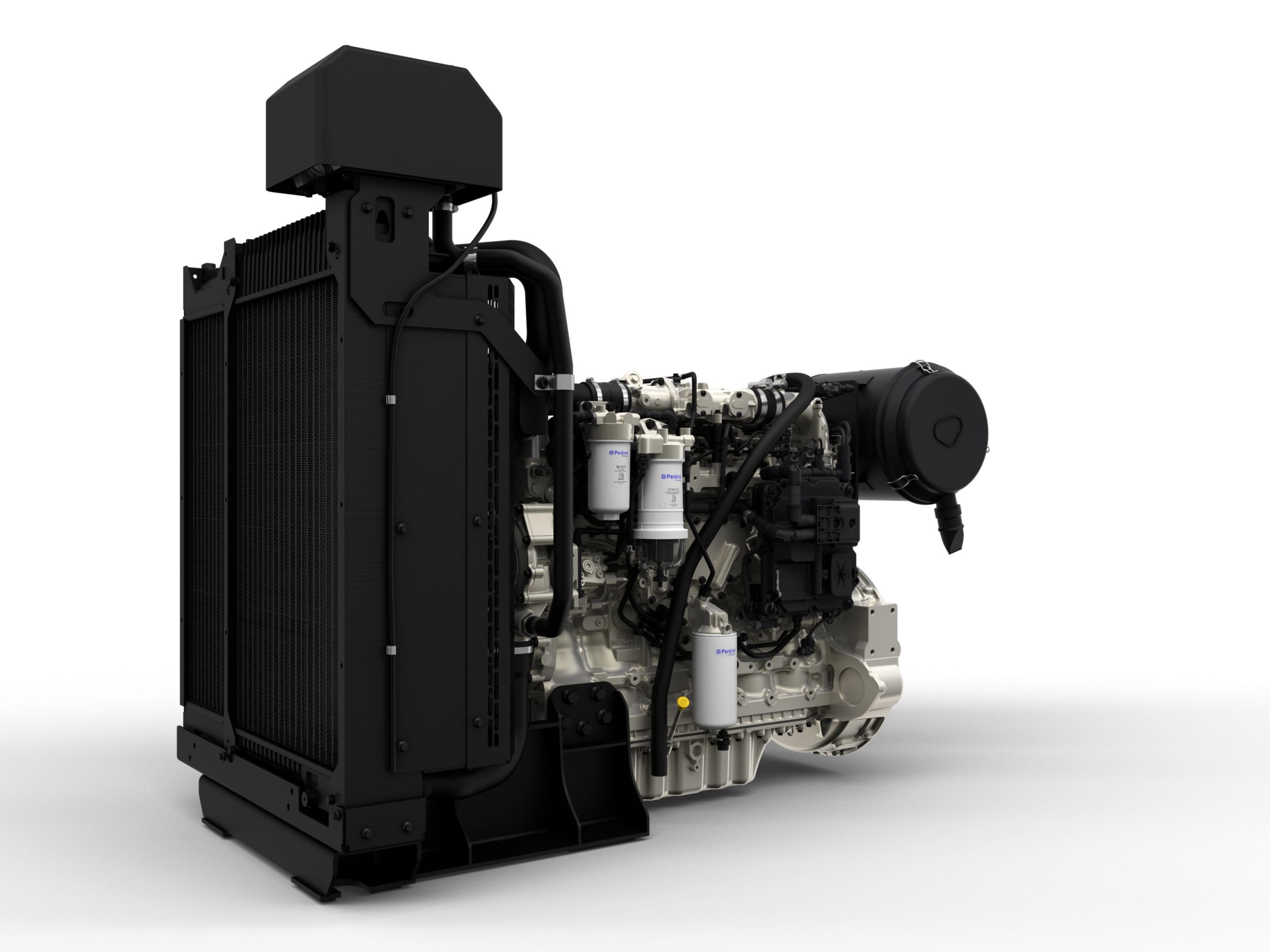

Perkins is pleased to announce the natural expansion of the 1200 Series to include a new addition to the ElectropaK range.</p> The whole engine has been built around the demands of our customers and as such offers a great package with a simple integration design.</p> Perkins have developed a reputation for designing and building reliable and durable engines suitable for the most demanding applications.

Specifications

| Gross Mechanical Output | 186 -248.5 kWm |

| Typical Electrical Output | 200-275 kVA (160-220 kWe) |

| Emissions | Fuel Optimised |

Benefits & Features

Dependable power

World-class manufacturing capability and processes coupled with proven core engine designs assure reliability, quiet operation, and many hours of productive life.

Series turbocharging with smart wastegate available on all ratings. A high power density product that combine dependable power and high efficiency at the same time. Driving lower cost of ownership along with better performance. To find more, visit: www.perkins.com/powerdensityIndustry leading flexibility

Perkins is proud to offer unrivalled flexibility and our EP engines are no exception. A tropical radiator is supplied as standard.

Lifetime of low cost

Fuel consumption optimized prime power and continuous running applications. No additional fluids or additives are required which lowers operating costs.

Hydraulic tappets, multi-vee belts, service free aftertreatment and 500 hour oil change intervals also keep your maintenance costs as low as possible.Specifications

| Gross Mechanical Output | 186 -248.5 kWm |

| Typical Electrical Output | 200-275 kVA (160-220 kWe) |

| Rated Speed | 1500/1800 rpm |

| Prime | 200-250 kVA |

| Standby | 225-275 kVA |

| Prime | 180 kWe |

| Standby | 200 kWe |

| Emissions | Fuel Optimised |

| Number of Cylinders | 6 vertical inline |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Compression Ratio | 15.8:1 |

| Aspiration | Twin turbocharged aftercooled |

| Combustion System | Direct injection |

| Rotation from Flywheel End | Anti-clockwise |

| Cooling System | Liquid |

| Aftertreatment | - |

| Typical Alternator Efficiency | 89.5-92% |

| Switchable | Yes |

| Length | — |

| Width | — |

| Height | — |

| Dry Weight | — |

| Note 1 | *Final dimensions dependent on selected options |

| Prime Power | Power available at variable load in lieu of a main power network. Overload of 10% is permitted for one hour in every 12 hours of operation. |

| Standby Power | Power available at variable load in the event of a main power network failure. No overload is permitted. |

Benefits & Features

Dependable power

World-class manufacturing capability and processes coupled with proven core engine designs assure reliability, quiet operation, and many hours of productive life.

Series turbocharging with smart wastegate available on all ratings. A high power density product that combine dependable power and high efficiency at the same time. Driving lower cost of ownership along with better performance. To find more, visit: www.perkins.com/powerdensityIndustry leading flexibility

Perkins is proud to offer unrivalled flexibility and our EP engines are no exception. A tropical radiator is supplied as standard.

Lifetime of low cost

Fuel consumption optimized prime power and continuous running applications. No additional fluids or additives are required which lowers operating costs.

Hydraulic tappets, multi-vee belts, service free aftertreatment and 500 hour oil change intervals also keep your maintenance costs as low as possible.Data not available.

Standard Equipment

- Air inlet system

- Standard air cleaners

- Cooling system

- 50:50 water glycol mix

- Tropical radiator as standard ensures optimal cooling performances all year round in any state

- Control system

- Flexible and configurable software features and well supported SAE J1939 CAN bus enables highly integrated machines

- Full electronic control system, all connectors and wiring looms waterproof and designed to withstand harsh off-highway environments

- Flywheels and flywheel housing

- SAE No. 2 flywheel housing

- Fuel system

- Electronic high pressure common rail

- Innovative filter design - ensures maximum protection of the engine

- Oil system

- Flat bottomed, isolated, aluminum sump

- Standard emissions control equipment

- NRS – NOx Reduction System