Overview

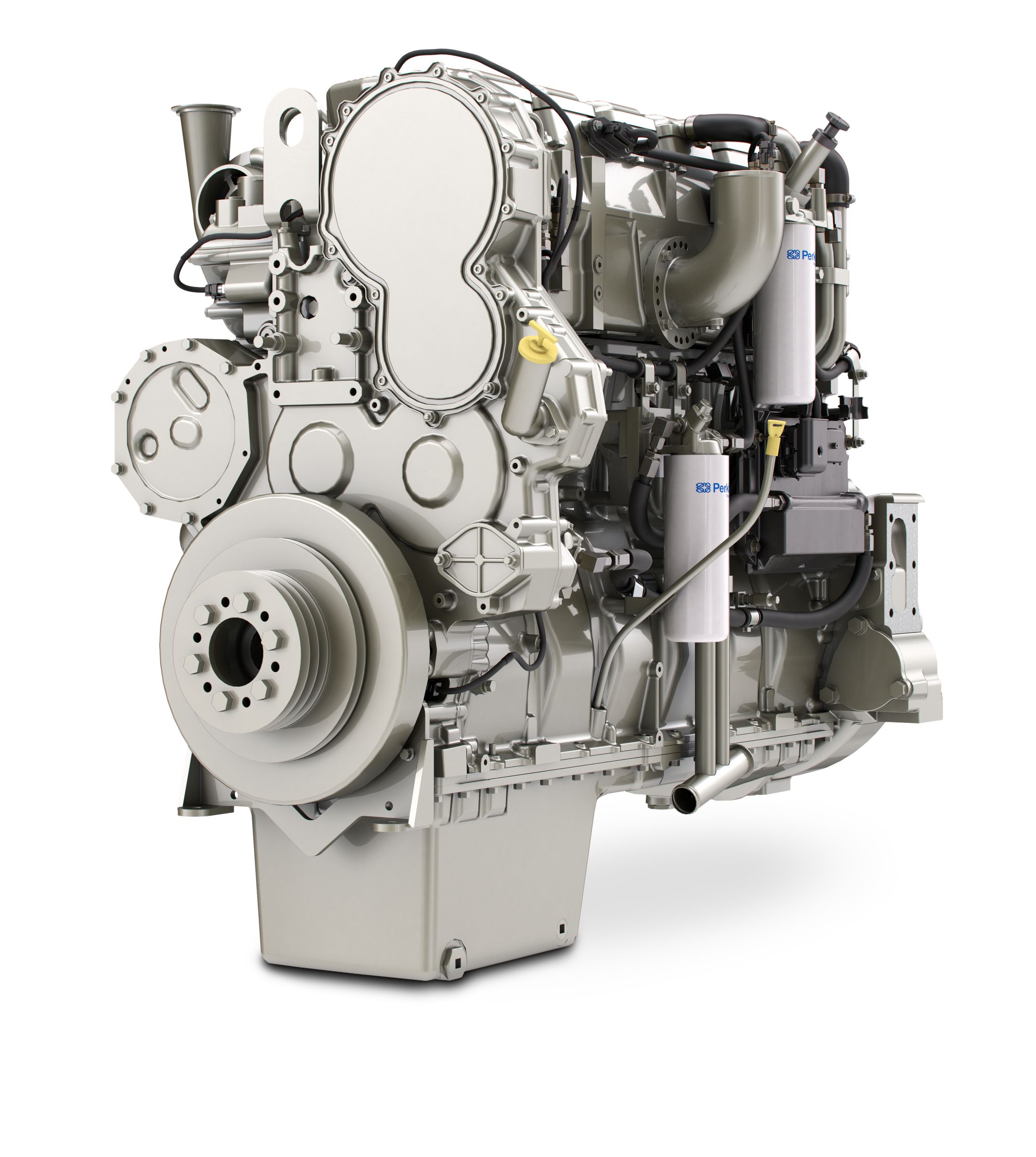

The Perkins 2800 Series is a family of well-proven 6 cylinder, 18 litre in-line diesel engines, designed to address today’s uncompromising demands within the power generation industry with particular aim at the standby market sector. Developed from a proven heavy-duty industrial base, the engine offers superior performance and reliability. The 2806A-E18TTAG is a series turbocharged and air-to-air charge cooled, 6 cylinder diesel engine of 18 litres capacity. </p>Its premium features provide economic and durable operation, low gaseous emissions and advanced overall performance and reliability. Unregulated

Specifications

| Gross Mechanical Output | 623-821 kWm |

| Typical Electrical Output | 706 - 938 kVA (565 - 750 kWe) |

| Emissions | Fuel Optimised |

Benefits & Features

Economic power

• Mechanically operated unit fuel injectors with electronic control combined with carefully matched turbocharging give excellent fuel atomisation and combustion with optimum economy

• Low emissions result from electronic control of fuel injected

Reliable power

• Developed and tested using the latest engineering techniques and finite element analysis for high reliability, low oil usage and low wear rates

• High compression ratios also ensure clean rapid starting in all conditions

• Perkins global product support is designed to enhance the customer experience of owning a Perkins powered machine. We deliver this through the quality of our distribution network, extensive global coverage and a range of Perkins supported OEM partnership options. So whether you are an end-user or an equipment manufacturer our engine expertise is essential to your success

Compact, clean and efficient power

• Exceptional power to weight ratio and compact size give optimum power density with easier installation and cost effective transportation

• Designed to provide excellent service access for ease of maintenance

• The availability of a low emissions specification allows minimum environmental impact through operation, and complies with US EPA emissions legislation. The standard specification model provides superior fuel consumption which maximises engine efficiency

Specifications

| Gross Mechanical Output | 623-821 kWm |

| Typical Electrical Output | 706 - 938 kVA (565 - 750 kWe) |

| Rated Speed | 1500/1800 rpm |

| Prime | 706-770 kVA |

| Standby | 780-850 kVA |

| Prime | 642-680 kWe |

| Standby | 710-750 kWe |

| Emissions | Fuel Optimised |

| Number of Cylinders | 6 vertical inline |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Compression Ratio | 14:01 |

| Aspiration | Parallel turbocharged and air-to-air charge cooled |

| Combustion System | Direct injection |

| Rotation from Flywheel End | Anti-clockwise |

| Cooling System | Liquid |

| Aftertreatment | - |

| Typical Alternator Efficiency | 95% |

| Switchable | Yes |

| Length | — |

| Width | — |

| Height | — |

| Dry Weight | — |

| Note 1 | *Final dimensions dependent on selected options |

| Prime Power | Power available at variable load in lieu of a main power network. Overload of 10% is permitted for one hour in every 12 hours of operation. |

| Standby Power | Power available at variable load in the event of a main power network failure. No overload is permitted. |

Benefits & Features

Economic power

• Mechanically operated unit fuel injectors with electronic control combined with carefully matched turbocharging give excellent fuel atomisation and combustion with optimum economy

• Low emissions result from electronic control of fuel injected

Reliable power

• Developed and tested using the latest engineering techniques and finite element analysis for high reliability, low oil usage and low wear rates

• High compression ratios also ensure clean rapid starting in all conditions

• Perkins global product support is designed to enhance the customer experience of owning a Perkins powered machine. We deliver this through the quality of our distribution network, extensive global coverage and a range of Perkins supported OEM partnership options. So whether you are an end-user or an equipment manufacturer our engine expertise is essential to your success

Compact, clean and efficient power

• Exceptional power to weight ratio and compact size give optimum power density with easier installation and cost effective transportation

• Designed to provide excellent service access for ease of maintenance

• The availability of a low emissions specification allows minimum environmental impact through operation, and complies with US EPA emissions legislation. The standard specification model provides superior fuel consumption which maximises engine efficiency

Data not available.

Standard Equipment

- Air inlet system

- Mounted air filter

- Cooling system

- Gear driven circulating pump

- Low coolant level switch

- Mounted belt driven pusher fan

- Radiator incorporating air-to-air charge cooler, (supplied loose)

- System designed for ambients up to 50ºC (122ºF)

- Electrical equipment

- 3 level engine protection system

- 24 volt starter motor and 24 volt 50 amp alternator with DC output

- ECM mounted on engine with wiring looms and sensors

- Flywheels and flywheel housing

- High inertia flywheel to SAE J620 size 14

- SAE 1 flywheel housing

- Fuel system

- Fuel cooler

- Governing to ISO 8528-5 class G2 with isochronous capability

- Mechanically actuated electronically controlled unit fuel injectors with full authority electronic control

- Replaceable fuel filter elements with primary filter/water separator

- Mountings

- Front engine mounting bracket

- Oil system

- Full flow replaceable filter

- Oil cooler integral with filter header

- Wet sump with filler and dipstick