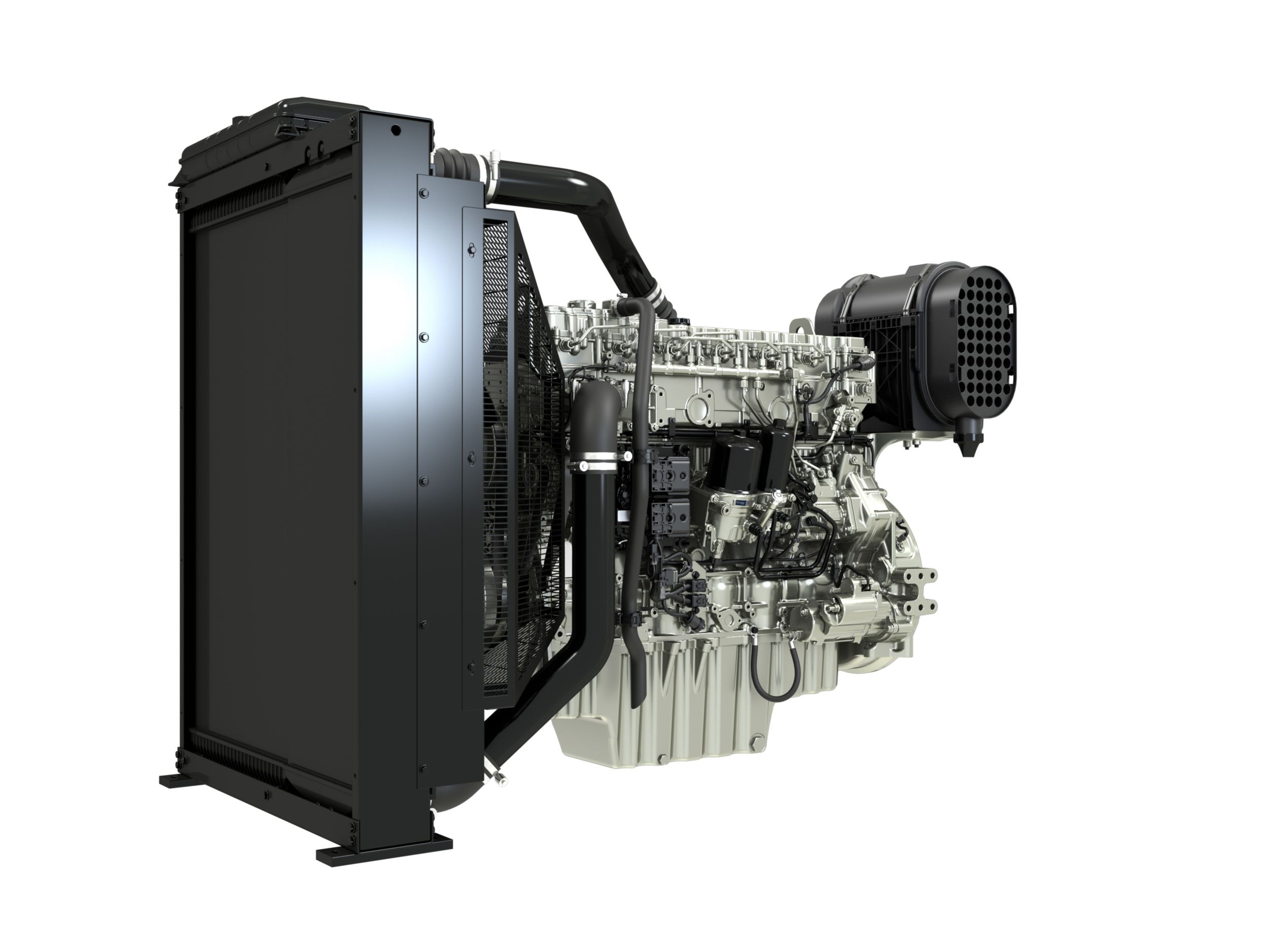

2606C-E13TAG

2606C-E13TAG - Emits equivalent to EU Stage IIOverview

The Perkins® 2606C-E13TAG is a 6 cylinder, fully electronic, common-rail direct injected, turbocharged, air-to-air aftercooled, generator set engine. The 2606C-E13TAG ElectropaK emits equivalent to EU Stage II, and can switch between 50 Hz and 60 Hz frequencies. The 2606C-E13TAG models can be changed over to respective fuel optimised 2606A-E13TAG model variants for countries without emission standards.

Specifications

| Gross Mechanical Output | 321-518 kW |

| Typical Electrical Output | 350-563 kVA (280-450 kWe) |

| Emissions | Emits equivalent to EU Stage II |

Benefits & Features

Quick Startup

Reliable power generation with rapid starting whilst delivering impressive steady state and transient response - up to 96% cold prime first step, G2.

Ease of Serviceability

Hydraulic lash adjusters, oil filter drain-backs, electric priming pumps, a water-in-fuel sensor, a single convenient electronic connection point, and the removal of all loose washers make interacting with the Perkins® 2606 service-, maintenance-, and installation-friendly.

Lower Total Cost of Ownership

Periodic operating and running costs reduced from optimised fuel consumption. Maximise uptime in harsh environments with fuel systems robust to various regional diesel fuels, keeping service costs low with up to 1,000-hour oil and fuel service change intervals.

Specifications

| Gross Mechanical Output | 321-518 kW |

| Typical Electrical Output | 350-563 kVA (280-450 kWe) |

| Rated Speed | 1500/1800 rpm |

| Prime | 350-500 kVA |

| Standby | 400-550 kVA |

| Prime | 320-410 kWe |

| Standby | 350-450 kWe |

| Emissions | Emits equivalent to EU Stage II |

| Number of Cylinders | 6 vertical inline |

| Displacement | — |

| Aspiration | Turbocharged aftercooled |

| Bore | — |

| Stroke | — |

| Combustion System | Common rail direct injection |

| Compression Ratio | 18:1 |

| Aftertreatment | None |

| Total Lubricating Oil Capacity | — |

| Total Coolant Capacity | — |

| Rotation from Flywheel End | Anti-clockwise |

| Cooling System | Liquid |

| Typical Alternator Efficiency | 92% |

| Switchable | Yes |

| Length | — |

| Width | — |

| Height | — |

| Dry Weight | — |

| Wet Weight | — |

| Note 1 | *Final dimensions dependent on selected options |

| Prime Power | Unlimited hours usage with an average load factor of 70 percent of the published prime power over each 24 hour period. A 10 percent overload is available for one hour in every 12 hours operation. No overload is permitted. |

| Standby Power | Limited to 500 hours annual usage with an average load factor of 70 percent of the published standby power over each 24 hour period. Up to 300 hours of annual usage may be run continuously. No overload is permitted. |

Benefits & Features

Quick Startup

Reliable power generation with rapid starting whilst delivering impressive steady state and transient response - up to 96% cold prime first step, G2.

Ease of Serviceability

Hydraulic lash adjusters, oil filter drain-backs, electric priming pumps, a water-in-fuel sensor, a single convenient electronic connection point, and the removal of all loose washers make interacting with the Perkins® 2606 service-, maintenance-, and installation-friendly.

Lower Total Cost of Ownership

Periodic operating and running costs reduced from optimised fuel consumption. Maximise uptime in harsh environments with fuel systems robust to various regional diesel fuels, keeping service costs low with up to 1,000-hour oil and fuel service change intervals.

Durable in Extreme Climates

Capable of performing in ambient temperatures up to 60°C and altitudes as high as 3,500 metres without fuel derates.

Data not available.

Standard Equipment

- Electro unit or ElectropaK

- ElectropaK

- Radiator fitted

- Yes

- Fuel filter, engine mounted

- Yes

- Water separator

- Yes

- Fuel water sight glass

- Yes

- Fuel priming pump (manual/electric)

- Electric

- WIF sensor

- Yes

- Fuel cooler

- None

- Air filter, engine mounted

- Yes

- Engine ECM, engine mounted

- Yes

- Wiring harness to ECM

- Yes

- Wiring harness (all connectors to single customer interface)

- Yes

- Battery charging alternator

- Yes

- Flywheel housing

- Yes

- Flywheel

- Yes

- Fan

- Yes

- Fan guard

- Yes

- Temperature and oil pressure for automatic stop/alarm configurable

- Yes