Overview

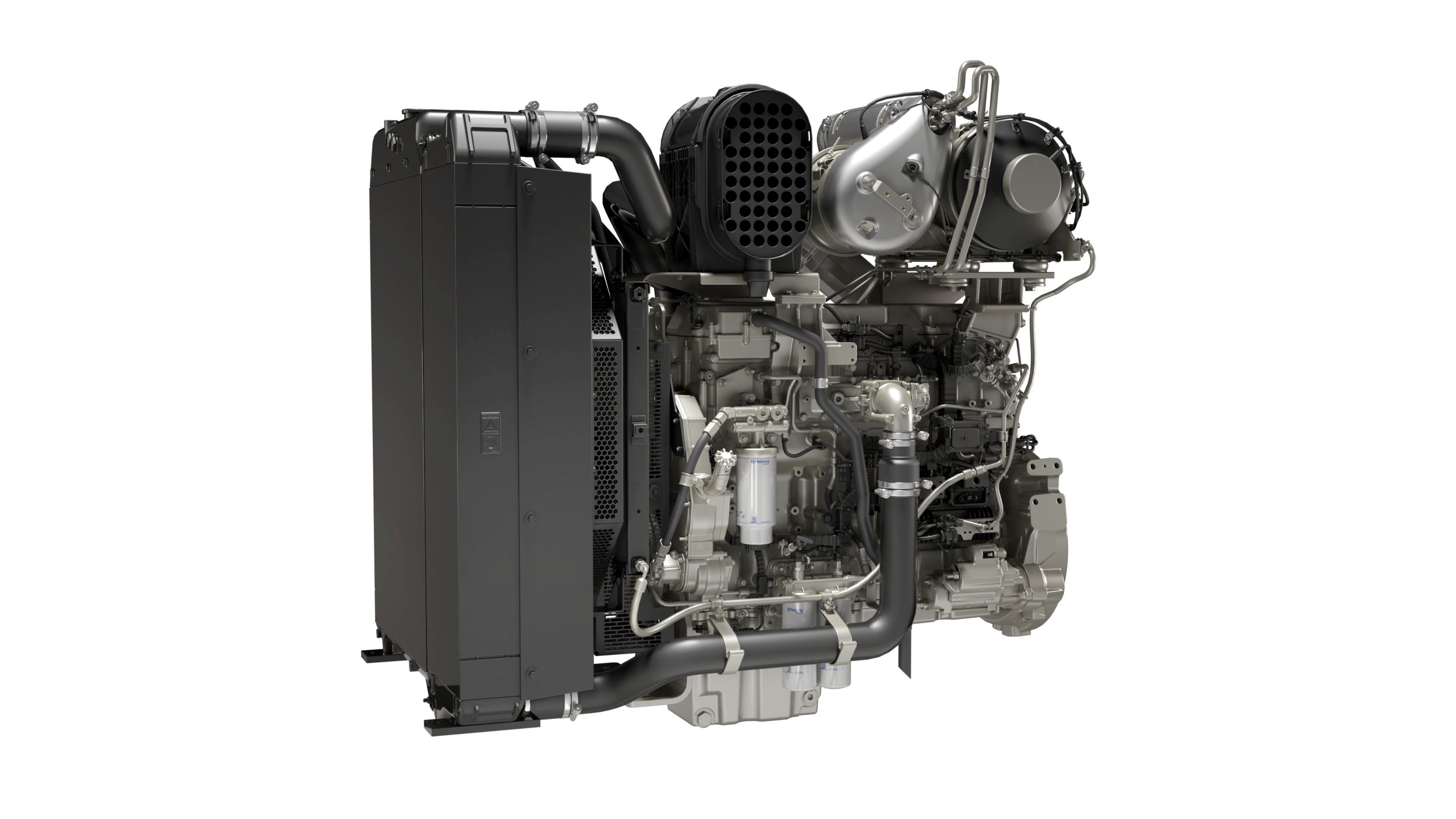

The Perkins® 2000 Series is a family of well-proven 6 cylinder 13, 15, and 18 litre diesel engines, designed to address today’s uncompromising demands within the power generation industry.

The 2000 Series is engineered to provide outstanding performance and maximise competitive advantage for our customers.

Developed on a latest generation 12.5 litre core, the 2406 offers greater capability and more flexibility to our customers from a simple plug and play product.

Specifications

| Gross Mechanical Output | 362-426 kWm |

| Typical Electrical Output | 410-474 kVA (328-379 kWe) |

| Emissions | EU Stage V/U.S. EPA Tier 4 Final |

Benefits & Features

Maximised productivity

Maximised productivity by achieving key power nodes with clean rapid starting whilst delivering impressive steady state and transient response.

Options between EU Stage V certified products for the EU mobile generator set market and U.S. EPA Tier 4 Final certified products for the U.S. mobile generator set market provides flexibility for our customers and tailored to their needs.

Exceptional power density

Exceptional power density enables standardisation across numerous applications providing ease of integration and service accessibility.

Better packaging options ship loose or engine mounted aftertreatment.

Simplified aftertreatment solution compatible with switchable Stage V and Tier 4 Final solution.

Optimised fuel consumption and low oil consumption

The 2000 Series offers optimised fuel consumption and low oil consumption whilst meeting the Stage V and Tier 4 Final emissions standards; all delivered from a proven reliable core engine delivering low daily operating costs.

Specifications

| Gross Mechanical Output | 362-426 kWm |

| Typical Electrical Output | 410-474 kVA (328-379 kWe) |

| Rated Speed | 1500/1800 rpm |

| Prime | 410 KVA |

| Standby | 452 kVA |

| Prime | 342 kWe |

| Standby | 379 kWe |

| Emissions | EU Stage V/U.S. EPA Tier 4 Final |

| Number of Cylinders | 6 vertical inline |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Compression Ratio | 15.8:1 |

| Aspiration | Turbocharged aftercooled |

| Combustion System | Direct injection |

| Rotation from Flywheel End | Anti-clockwise |

| Cooling System | Liquid |

| Aftertreatment | DOC+DPF+SCR+AMOX+DEF |

| Switchable | Yes |

| Length | — |

| Width | — |

| Height | — |

| Dry Weight | — |

| Note 1 | *Final dimensions dependent on selected options |

| Note 2 | *Generator powers are typical and based on typical alternator efficiencies and a power factor (cos ?) or 0.8 |

| Prime Power | Power available at variable load in lieu of a main power network. Overload of 10% is permitted for one hour in every 12 hours of operation. |

| Standby Power | Power available at variable load in the event of a main power network failure. No overload is permitted |

Benefits & Features

Maximised productivity

Maximised productivity by achieving key power nodes with clean rapid starting whilst delivering impressive steady state and transient response.

Options between EU Stage V certified products for the EU mobile generator set market and U.S. EPA Tier 4 Final certified products for the U.S. mobile generator set market provides flexibility for our customers and tailored to their needs.

Exceptional power density

Exceptional power density enables standardisation across numerous applications providing ease of integration and service accessibility.

Better packaging options ship loose or engine mounted aftertreatment.

Simplified aftertreatment solution compatible with switchable Stage V and Tier 4 Final solution.

Optimised fuel consumption and low oil consumption

The 2000 Series offers optimised fuel consumption and low oil consumption whilst meeting the Stage V and Tier 4 Final emissions standards; all delivered from a proven reliable core engine delivering low daily operating costs.

Low periodic running costs.

Perkins engines are designed and developed with our customers in mind.

Keeping service cost to a minimum enables low periodic running costs. This is achieved through 500 hour service intervals for oil and fuel as standard under all operating conditions.

Long productive life

The long productive life of our products is supported through the Perkins 12 month warranty as standard for prime power applications, and the 1500 hour or two year emissions warranty.

For further peace of mind, there is also the option to extend the warranty period through Perkins® Platinum Protection. Contact your local distributor or visit www.perkins.com/platinumprotection.

Efficient processes and stringent quality controls

Engines are produced using the Caterpillar Production System established in all Perkins manufacturing operations, achieving the same efficient processes and stringent quality controls at every global facility.

Data not available.

Standard Equipment

- Air inlet system

- Engine mounted air filter

- Cooling system

- Radiator fitted

- Fan

- Fan Guard

- Electrical equipment

- ECM mounted on engine with wiring looms and sensors

- Wiring harness (all connectors to single customer interface)

- Starter motor

- Battery charging alternator

- Flywheels and flywheel housing

- Flywheel

- Flywheel housing

- Fuel system

- Engine mounted fuel filter

- Manual fuel priming pump

- Oil system

- Temperature and oil pressure for automatic stop/alarm configurable