Overview

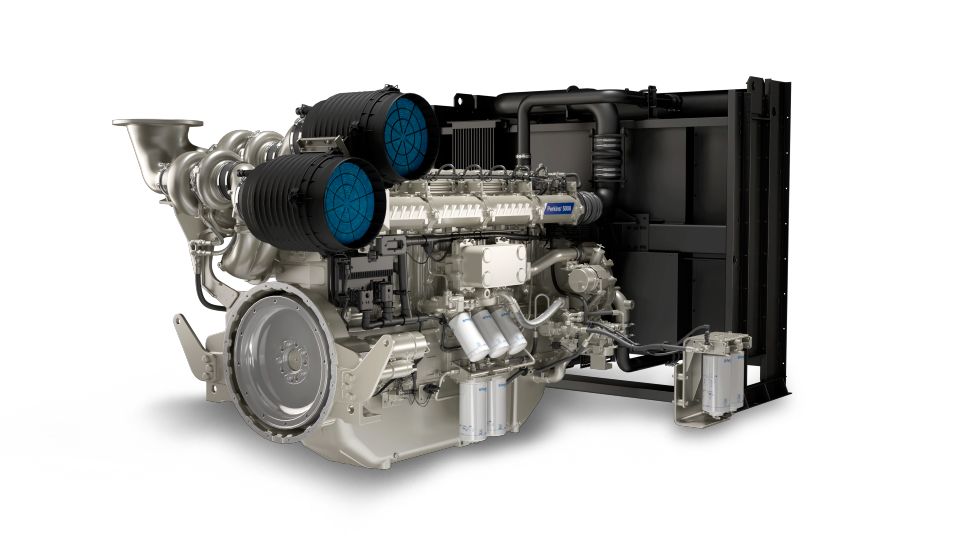

The Perkins® 5008C-E30TAG has been designed to offer reliable power for the emergency standby and critical applications market, including data centres and hospitals among others.

Engineered and built specifically for the power generation market, the Perkins 5000 Series is a power-packed engine range built to be dependable, versatile and offer lower emissions to meet regulatory standards.

Specifications

| Gross Mechanical Output | 907-1107 kWm |

| Typical Electrical Output | 1012-1250 kVA (810-1000 kWe) |

| Emissions | US EPA Stationary Emergency-Use-Only (Tier 2) |

Benefits & Features

Maximised productivity

The 5000 Series delivers maximised productivity through excellent load acceptance, achieving NFPA110 Type 10 and ISO 8528-5 G2 and G3 performance class.

The engine build and performance have been designed with ultimate productivity and dependability in mind, so customers can be confident that power will be available when required.

They have been tested around the world, in the harshest environments imaginable, to ensure that performance, no matter the conditions.

Advanced technology

The 5000 Series utilises advanced technology, with full authority electronics, that easily integrate into the customer’s chosen telematic solutions and are certified to U.S. EPA Tier 2 emission standards.

We offer an optional closed crankcase ventilation system to reduce crankcase emissions further, if required.

Integration and service accessibility

A single point electronics connection ensures ease of integration and service accessibility is provided from a single side with two year oil and fuel service intervals.

Specifications

| Gross Mechanical Output | 907-1107 kWm |

| Typical Electrical Output | 1012-1250 kVA (810-1000 kWe) |

| Rated Speed | 1800 rpm |

| Prime | 810-900 kWe |

| Standby | 900-1000 kWe |

| Emissions | US EPA Stationary Emergency-Use-Only (Tier 2) |

| Number of Cylinders | 8 vertical in-line |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Compression Ratio | 12.8:1 |

| Aspiration | Turbocharged and air-to-air chargecooled |

| Combustion System | Direct injection |

| Rotation from Flywheel End | Anti-clockwise, viewed from flywheel end |

| Cooling System | Watercooled |

| Aftertreatment | - |

| Typical Alternator Efficiency | 95 % |

| Switchable | No |

| Length | — |

| Width | — |

| Height | — |

| Dry Weight | — |

| Note 1 | *Final dimensions dependent on selected options |

Benefits & Features

Maximised productivity

The 5000 Series delivers maximised productivity through excellent load acceptance, achieving NFPA110 Type 10 and ISO 8528-5 G2 and G3 performance class.

The engine build and performance have been designed with ultimate productivity and dependability in mind, so customers can be confident that power will be available when required.

They have been tested around the world, in the harshest environments imaginable, to ensure that performance, no matter the conditions.

Advanced technology

The 5000 Series utilises advanced technology, with full authority electronics, that easily integrate into the customer’s chosen telematic solutions and are certified to U.S. EPA Tier 2 emission standards.

We offer an optional closed crankcase ventilation system to reduce crankcase emissions further, if required.

Integration and service accessibility

A single point electronics connection ensures ease of integration and service accessibility is provided from a single side with two year oil and fuel service intervals.

Daily operating costs

Excellent oil consumption through dedicated piston, ring and liner assembly and superior fuel consumption deliver low daily operating costs.

Data not available.

Standard Equipment

- Air inlet system

- Engine mounted air filter

- Cooling system

- Radiator supplied loose

- Fan and fan guards supplied

- Electrical equipment

- Engine mounted ECM

- Wiring harness to ECM and all connectors to single customer interface supplied

- Elecrtical equipment

- Starter motor and battery charging alternator

- Flywheel and flywheel housing

- Flywheel and flywheel housing options

- Fuel system

- Engine mounted fuel filter

- Electric fuel priming pump

- Fuel cooler supplied

- General

- Temperature and oil pressure for automatic stop/alarm configurable