Overview

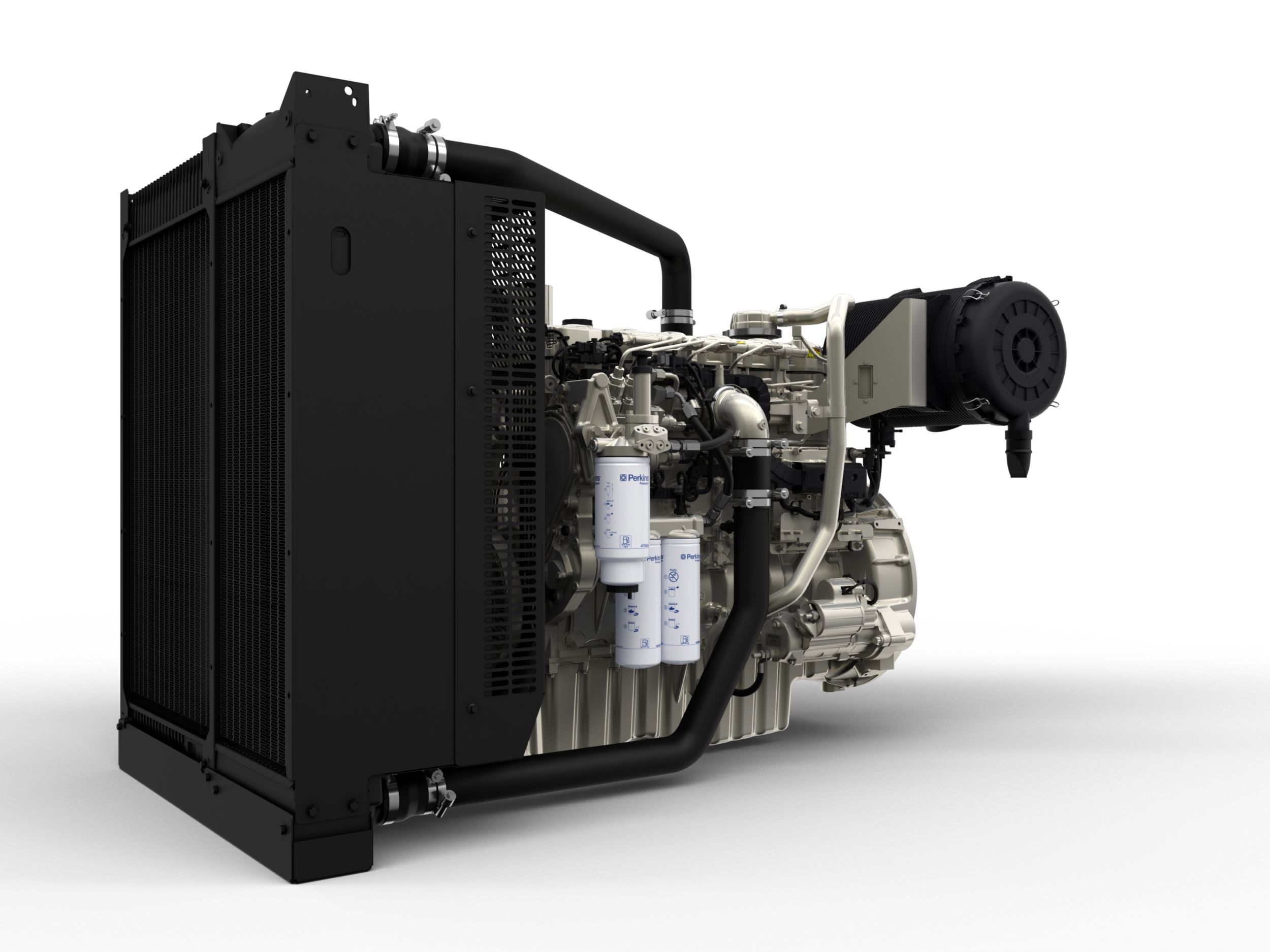

The Perkins® 1700 Series is engineered to provide class leading performance and maximise competitive advantage for our customers. Developed on a latest generation 9.3 litre core, the 1706 offers greater capability and more flexibility to our customers from a simple plug and play product.

Emissions - U.S. EPA Tier 3.

Specifications

| Gross Mechanical Output | 267-354 kWm |

| Typical Electrical Output | 296-397 kVA (237-318 kWe) |

| Emissions | US EPA Tier 3 |

Benefits & Features

Durability and Reliability

A high power density product that combines dependable power and high efficiency coupled with proven core engine designs assures maximum durability, reliability and quiet operation.

Easier Installation

Designed to provide more flexibility to our customers and offer a simple plug and play product allowing for easier installation.

Cost of Ownership

With fuel consumption optimized to both prime power and continuous running applications and the requirement for no additional fluids or additives result in lower cost of ownership.

Specifications

| Gross Mechanical Output | 267-354 kWm |

| Typical Electrical Output | 296-397 kVA (237-318 kWe) |

| Rated Speed | 1800 rpm |

| Prime | 237-288 kWe |

| Standby | 261-318 kWe |

| Emissions | US EPA Tier 3 |

| Number of Cylinders | 6 vertical inline |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Compression Ratio | 17.0:1 |

| Aspiration | Turbocharged aftercooled |

| Combustion System | Direct injection |

| Rotation from Flywheel End | Anti-clockwise |

| Cooling System | Liquid |

| Aftertreatment | - |

| Typical Alternator Efficiency | 93% |

| Switchable | No |

| Length | — |

| Width | — |

| Height | — |

| Dry Weight | — |

| Note 1 | *Final dimensions dependent on selected options |

| Prime Power | Power available at variable load in lieu of a main power network. Overload of 10% is permitted for one hour in every 12 hours of operation. |

| Standby Power | Power available at variable load in the event of a main power network failure. No overload is permitted. |

Benefits & Features

Durability and Reliability

A high power density product that combines dependable power and high efficiency coupled with proven core engine designs assures maximum durability, reliability and quiet operation.

Easier Installation

Designed to provide more flexibility to our customers and offer a simple plug and play product allowing for easier installation.

Cost of Ownership

With fuel consumption optimized to both prime power and continuous running applications and the requirement for no additional fluids or additives result in lower cost of ownership.

Lifetime of low cost

Throughout the life of a Perkins engine, we provide access to genuine OE specification parts along with vee belts and 500-hour oil change intervals enable low‑cost maintenance.

Productive Life

Perkins offer a range of flexible solutions to help provide appropriate support, either to the OEM’s network or directly to the machine customer. Our information systems enable our distributors to quickly diagnose engine faults and identify the right parts supported by the Perkins logistics operation ablility to dispatch more than 45,000 different parts from stock, reaching the customer within 24 hours helping to maximise the productive life of your engine.

High Quality as Standard

Perkins takes pride in manufacturing all products globally to the same high quality standard. All of our products are manufacctured in world class facilities to ensure highest quality for your peace of mind.

Data not available.

Standard Equipment

- Air inlet system

- Standard air cleaners

- Cooling system

- Tropical radiator as standard ensures optimal cooling performances all year round in any state

- 50:50 water glycol mix

- Control system

- Flexible and configurable software features and well supported SAE J1939 CAN bus enables highly integrated machines

- Full electronic control system. All connectors and wiring looms waterproof and designed to withstand harsh environments

- Flywheels and flywheel housing

- SAE1 flywheel housing

- Fuel system

- Electronic high pressure common rail

- Fuel filter, fuel transfer pump, fuel priming pump

- Oil system

- Aluminium sump