Overview

Building upon Perkins proven reputation within the power

generation industry the Perkins® 1500 Series Electropak engines

now fit even closer to our customer’s needs.

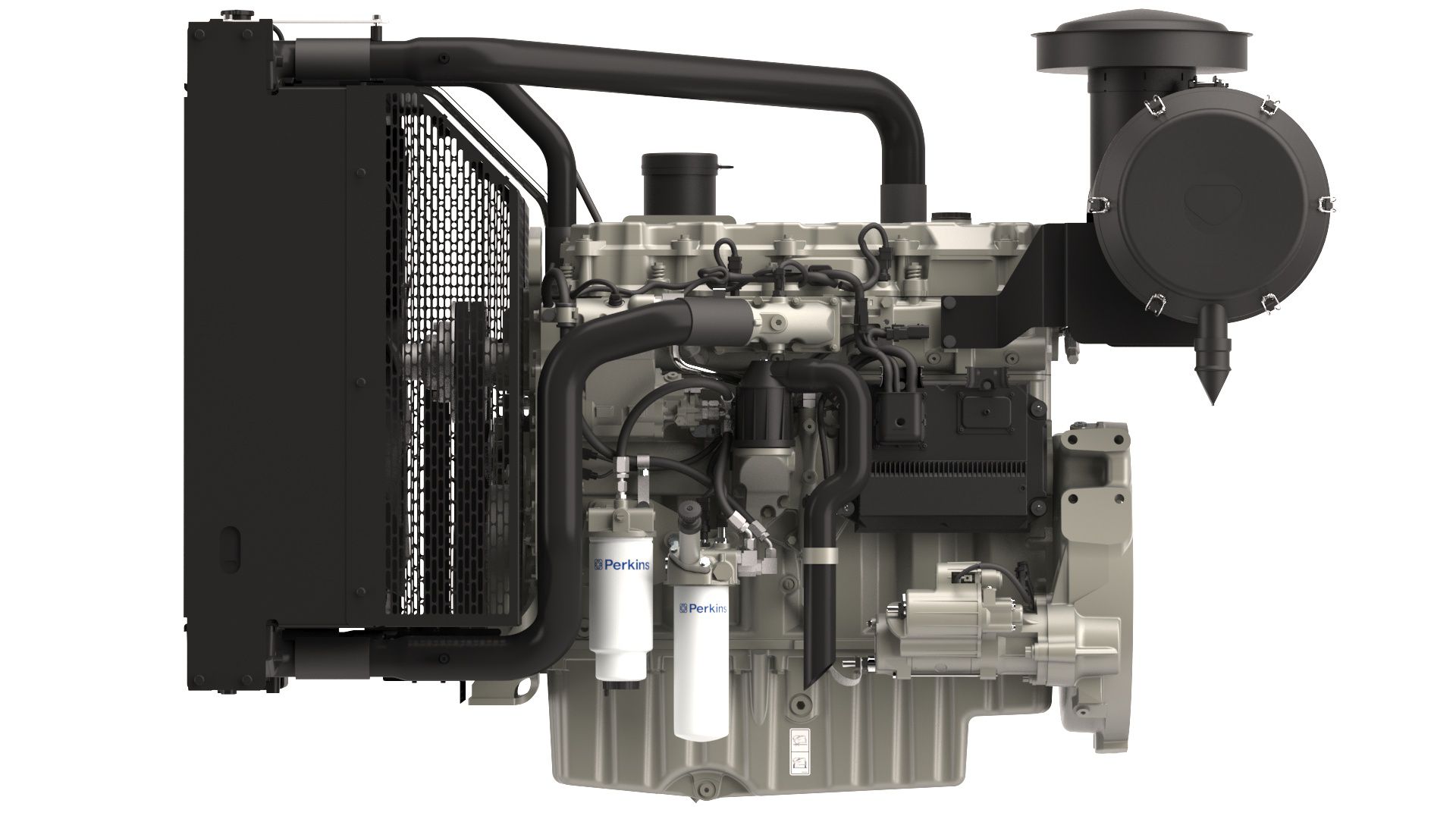

The 1506D-E88TAG3 ElectropaK is a 6 cylinder, fully electronic,

turbocharged, air-to-air charge cooled diesel engine. It is

economical, quiet and reliable and provides the high performance

that is demanded by our customers for their power generation

needs.

Focusing on the Perkins common platform theme, changes to

engine envelope dimensions and connection points have been

kept to a minimum, making for easy installation across the ratings.

This engine meets U.S. EPA Tier 3 Emergency Stationary Engines only.

Specifications

| Gross Mechanical Output | 275-358 kWm |

| Typical Electrical Output | 292-386 kVA (234-309 kWe) |

| Emissions | U.S. EPA Tier 3 |

Benefits & Features

Dependable power

1506D series delivers greater productivity through an improved power to weight ratio.

The world-class power density has been achieved from an 8.8 litre turbocharged engine using a hydraulic actuated

unit injection (HEUI) fuel system; making this engine robust for all markets due to its ability to cope with the variation

of fuel quality around the world.

Lower operating costs

The 1500 Series in designed to provide low cost of ownership, simple maintenance and reduced downtime. Oil change intervals are set at 500 hours as standard.

World class product support

Our experienced global network of distributors and dealers, fully trained engine experts deliver total service support

around the clock, 365 days a year. They have a comprehensive suite of web based tools at their disposal, covering

technical information, parts identification and ordering systems, all dedicated to maximising the productivity of your

engine

Specifications

| Gross Mechanical Output | 275-358 kWm |

| Typical Electrical Output | 292-386 kVA (234-309 kWe) |

| Rated Speed | 1800 rpm |

| Prime | 234-282 kWe |

| Standby | 254-309 kWe |

| Emissions | U.S. EPA Tier 3 |

| Number of Cylinders | 6 vertical inline |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Compression Ratio | 16.1:1 |

| Aspiration | Turbocharged aftercooled |

| Combustion System | Direct injection |

| Rotation from Flywheel End | Anti-clockwise |

| Cooling System | Liquid |

| Aftertreatment | - |

| Typical Alternator Efficiency | 92% |

| Switchable | Yes |

| Length | — |

| Width | — |

| Height | — |

| Dry Weight | — |

| Note 1 | *Final dimensions dependent on selected options |

| Prime Power | Variable load. Unlimited hours usage with an average load of 70% of the published prime power rating. A 10% overload is available for 1 hour in every 12 hour of operation. |

| Standby Power | Variable load. Limited to 500 hours annual usage up to 300 hours of which may be continuous running. No overload is permitted. |

Benefits & Features

Dependable power

1506D series delivers greater productivity through an improved power to weight ratio.

The world-class power density has been achieved from an 8.8 litre turbocharged engine using a hydraulic actuated

unit injection (HEUI) fuel system; making this engine robust for all markets due to its ability to cope with the variation

of fuel quality around the world.

Lower operating costs

The 1500 Series in designed to provide low cost of ownership, simple maintenance and reduced downtime. Oil change intervals are set at 500 hours as standard.

World class product support

Our experienced global network of distributors and dealers, fully trained engine experts deliver total service support

around the clock, 365 days a year. They have a comprehensive suite of web based tools at their disposal, covering

technical information, parts identification and ordering systems, all dedicated to maximising the productivity of your

engine

Data not available.

Standard Equipment

- Air inlet system

- Mounted air filter and turbocharger

- Cooling system

- Air-to-air charge cooler incorporated in radiator

- Mounted belt driven pusher fan

- Radiator supplied loose with all guards and pipes

- Thermostatically controlled with belt driven, circulating pump and belt-drive fan

- Electrical equipment

- 24 volt starter motor and 24 volt 45 amp alternator with DC output

- ECM mounted on engine with wiring looms and sensors

- Flywheels and flywheel housing

- Aluminium SAE 1 flywheel housing

- High inertia flywheel to SAE 1 J620 Size 355.6 mm (14 in)

- Fuel system

- Electronic governing to ISO 8528-5 with stand-alone isochronous and load-sharing capabilities

- Fuel filter, fuel transfer pump, fuel priming pump

- HEUI fuel system with full authority electronic control

- Spin on primary, secondary and water filter separator

- Mountings

- Front engine mounting bracket

- Oil System

- Wet full alumimum sump with filler and dipstick

- Full flow spin on filters

- Oil pump, gear driven