Overview

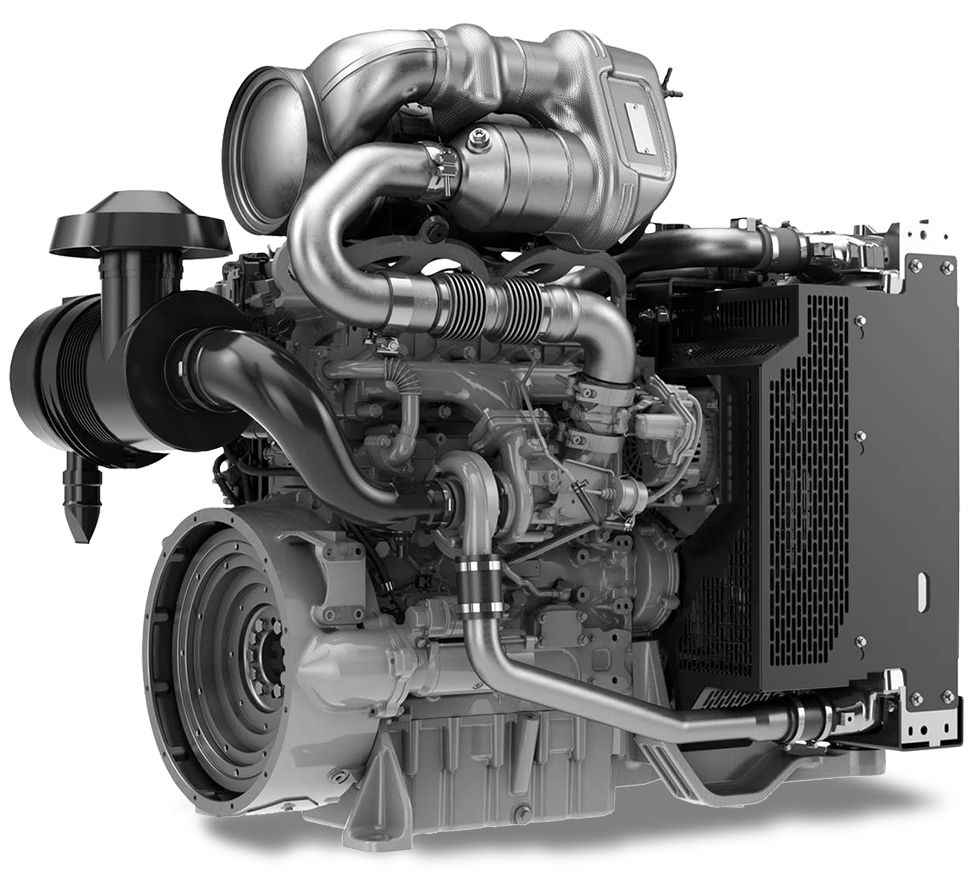

Perkins 1200 Series electric power engines deliver the power you need, when you need it. From hospitals to hotels, icy wastelands to scorching deserts, construction sites to factories – our engines provide the reliability, low operating costs and exceptional performance you need. Engines range from 4.4 to 7 litre, are turbocharged and chargecooled for extra power and load acceptance, while meeting the latest stringent emissions standards.

Designed to meet U.S. EPA Tier 4 Final emissions standards.Specifications

| Gross Mechanical Output | 117-129 kWm |

| Typical Electrical Output | 113.6-125 kVA (91-100 kWe) |

| Emissions | U.S. EPA Tier 4 Final |

Benefits & Features

Cutting-edge technology

Among the other benefits of our 1200 Series EP engines are a fully electronic fuel system for superior performance and low fuel consumption.

Industry leading flexibility

Perkins is proud to offer unrivalled flexibility and our EP engines are no exception. A tropical radiator is supplied as standard.

Lifetime of low cost

Fuel consumption on our engines has been optimised for prime power and continuous running applications, making them a clean and cost effective solution. Your running costs are also lowered by the fact that no additional fluids or additives are required to run or maintain your engine.

Hydraulic tappets, multi-vee belts, service free aftertreatment and 500 hour oil change intervals also keep your maintenance costs as low as possible.Specifications

| Gross Mechanical Output | 117-129 kWm |

| Typical Electrical Output | 113.6-125 kVA (91-100 kWe) |

| Rated Speed | 1800 rpm |

| Prime | 91 kWe |

| Standby | 100 kWe |

| Emissions | U.S. EPA Tier 4 Final |

| Number of Cylinders | 6 vertical inline |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Compression Ratio | 16.5:1 |

| Aspiration | Series turbocharged aftercooled |

| Combustion System | Direct injection |

| Rotation from Flywheel End | Anti-clockwise |

| Cooling System | Liquid |

| Aftertreatment | DOC+SCR |

| Typical Alternator Efficiency | 89% |

| Switchable | No |

| Length | — |

| Width | — |

| Height | — |

| Dry Weight | — |

| Length | — |

| Width | — |

| Height | — |

| Weight | — |

| Note 1 | *Final dimensions dependent on selected options |

| Prime Power | Power available at variable load in lieu of a main power network. Overload of 10% is permitted for one hour in every 12 hours of operation. |

| Standby Power | Power available at variable load in the event of a main power network failure. No overload is permitted. |

Benefits & Features

Cutting-edge technology

Among the other benefits of our 1200 Series EP engines are a fully electronic fuel system for superior performance and low fuel consumption.

Industry leading flexibility

Perkins is proud to offer unrivalled flexibility and our EP engines are no exception. A tropical radiator is supplied as standard.

Lifetime of low cost

Fuel consumption on our engines has been optimised for prime power and continuous running applications, making them a clean and cost effective solution. Your running costs are also lowered by the fact that no additional fluids or additives are required to run or maintain your engine.

Hydraulic tappets, multi-vee belts, service free aftertreatment and 500 hour oil change intervals also keep your maintenance costs as low as possible.Data not available.

Standard Equipment

- Aftertreatment technology

- 3 inch flex pipes available with a variety of elbow options for turbocharger connection

- DOC - Diesel Oxidation Catalyst

- SCR auxiliaries - a range of tanks and heated lines are available

- SCR - Selective Catalytic Reduction

- Air inlet system

- Standard air cleaners

- Cooling system

- Engine mounted radiator with top tank temperature of 108°C

- 50:50 water glycol mix

- Control system

- Flexible and configurable software features and well supported SAE J1939 CAN bus enables highly integrated machines

- Full electronic control system, all connectors and wiring looms waterproof and designed to withstand harsh off-highway environments

- Flywheels and flywheel housing

- Choice of drivetrain interfaces, supplied with SAE2 configuration as standard

- Fuel system

- Electronic high pressure common rail

- Standard and heavy duty fuel filtration

- Oil system

- Flat bottomed, isolated, aluminum sump

- Standard emissions control equipment

- NRS – NOx Reduction System