Overview

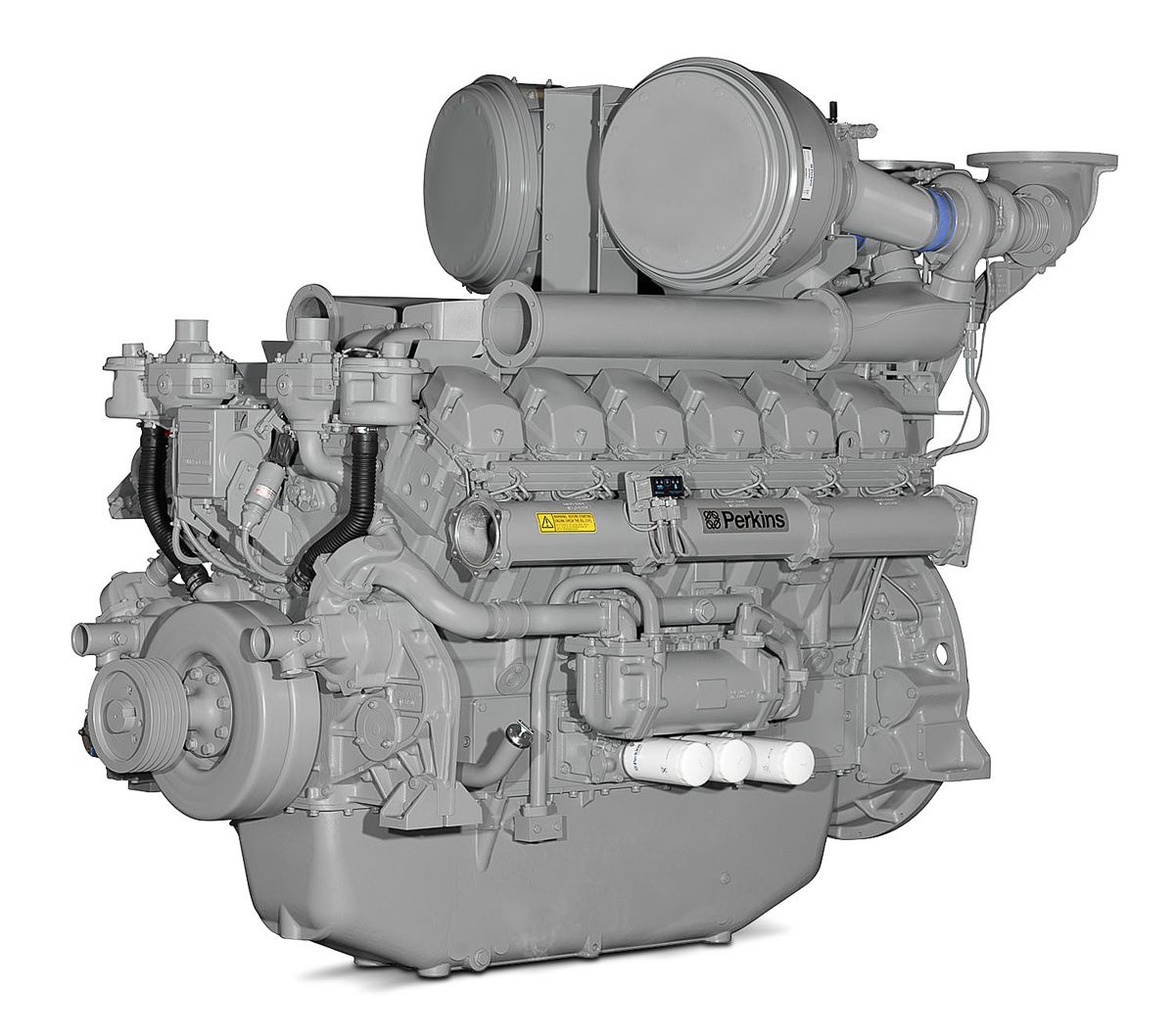

The Perkins 4012 range packs a real performance punch, with 12 cylinders and 46 litre displacement providing all the power you need. The range's diesel ElectropaK engines are supplied complete with radiator and air cleaner, or as engine only. They provide 1000-1880 kVA generator output, with exceptional power-to-weight ratios. The compact design of the engines makes them easy to transport and install.

The 4012-46TAG ElectropaK engine is turbocharged and air-to-air chargecooled. Designed to meet ½ TA Luft (1986) emissions standards.Specifications

| Gross Mechanical Output | 906-1643 kWm |

| Typical Electrical Output | 1000-1880 kVA (800-1504 kWe) |

| Emissions | Fuel Optimised |

Benefits & Features

Economy

Economic and durable, the engines have excellent power-to-weight ratios, as well as outstanding load acceptance and improved emissions.

Commonality of components with other engines in the 4000 Series makes replacing parts or upgrading an easy process.ElectropaK diesel

The ElectropaK diesel engines in the 4012 range come complete with radiator and air cleaner. Models in the range are either turbocharged and air-to-air chargecooled or turbocharged and air-to-water chargecooled.

Giving 1250-1880 kVA engine power, our 4012 range diesel engines include a model to suit all your power generation needs – prime or standby.

Engine-only options are also available.

Optional equipment

Options for your 4012 range diesel engines include:

• Fuel oil cooler integral to the radiator assembly • Immersion heater with thermostatSpecifications

| Gross Mechanical Output | 906-1643 kWm |

| Typical Electrical Output | 1000-1880 kVA (800-1504 kWe) |

| Rated Speed | 1500/1800 rpm |

| Prime | 1250-1710 kVA |

| Standby | 1375-1880 kVA |

| Baseload | 1000-1425 kVA |

| Prime | 1095-1368 kWe |

| Standby | 1204-1504 kWe |

| Baseload | 868-1140 kWe |

| Emissions | Fuel Optimised |

| Number of Cylinders | 12 Vee |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Compression Ratio | 13:1/13.6:1 |

| Aspiration | Turbocharged and air-to-air charge cooled |

| Combustion System | Direct injection |

| Rotation from Flywheel End | Anti-clockwise |

| Cooling System | Liquid |

| Aftertreatment | - |

| Typical Alternator Efficiency | 95% |

| Switchable | Available for some power nodes |

| Length | — |

| Width | — |

| Height | — |

| Dry Weight | — |

| Note 1 | *Final dimensions dependent on selected options |

| Prime Power | Unlimited hours usage with an average load factor of 80% of the published prime power over each 24 hours period. A 10% overload is available for 1 hour in every 12 hours operation. |

| Standby Power | Limited to 500 hours annual usage with an average load factor of 80% of the published standby power rating over each 24 hour period. Up to 300 hours of annual usage may be run continuously. No overload is permitted on standby power. |

| Baseload | Unlimited hours usage with an average load factor of 100% of the published baseload power. No overload is permitted on baseload power. |

Benefits & Features

Economy

Economic and durable, the engines have excellent power-to-weight ratios, as well as outstanding load acceptance and improved emissions.

Commonality of components with other engines in the 4000 Series makes replacing parts or upgrading an easy process.ElectropaK diesel

The ElectropaK diesel engines in the 4012 range come complete with radiator and air cleaner. Models in the range are either turbocharged and air-to-air chargecooled or turbocharged and air-to-water chargecooled.

Giving 1250-1880 kVA engine power, our 4012 range diesel engines include a model to suit all your power generation needs – prime or standby.

Engine-only options are also available.

Optional equipment

Options for your 4012 range diesel engines include:

• Fuel oil cooler integral to the radiator assembly • Immersion heater with thermostatData not available.

Standard Equipment

- Air inlet system

- Mounted air filter and turbochargers

- Cooling system

- Powder coated radiator comprising: water radiator; air charge cooled radiator; fuel oil cooling (optional); all pipes, hoses and clips; fan; pulleys; fan belts and safety guards

- System designed for ambients up to 50ºC (122ºF)

- Two twin thermostats

- Electrical equipment

- 24 volt starter motor and 24 volt alternator with integral regulator and DC output

- Overspeed switch and magnetic pickup

- Turbine inlet temperature shutdown switch

- Twin high coolant temperate shutdown switches

- Twin low oil pressure shutdown switches

- Flywheels and flywheel housing

- SAE 0 flywheel housing

- SAE J620 size 18 flywheel

- Fuel system

- Direct fuel injection system, fuel lift pump

- Full flow spin-on fuel oil filters

- Governing

- Governing to ISO 8528-5 class G2 with isochronous capability

- Oil system

- Engine jacket water/lubricating oil temperature stabiliser

- Full flow spin-on oil filters

- Wet sump with filler and dipstick