Overview

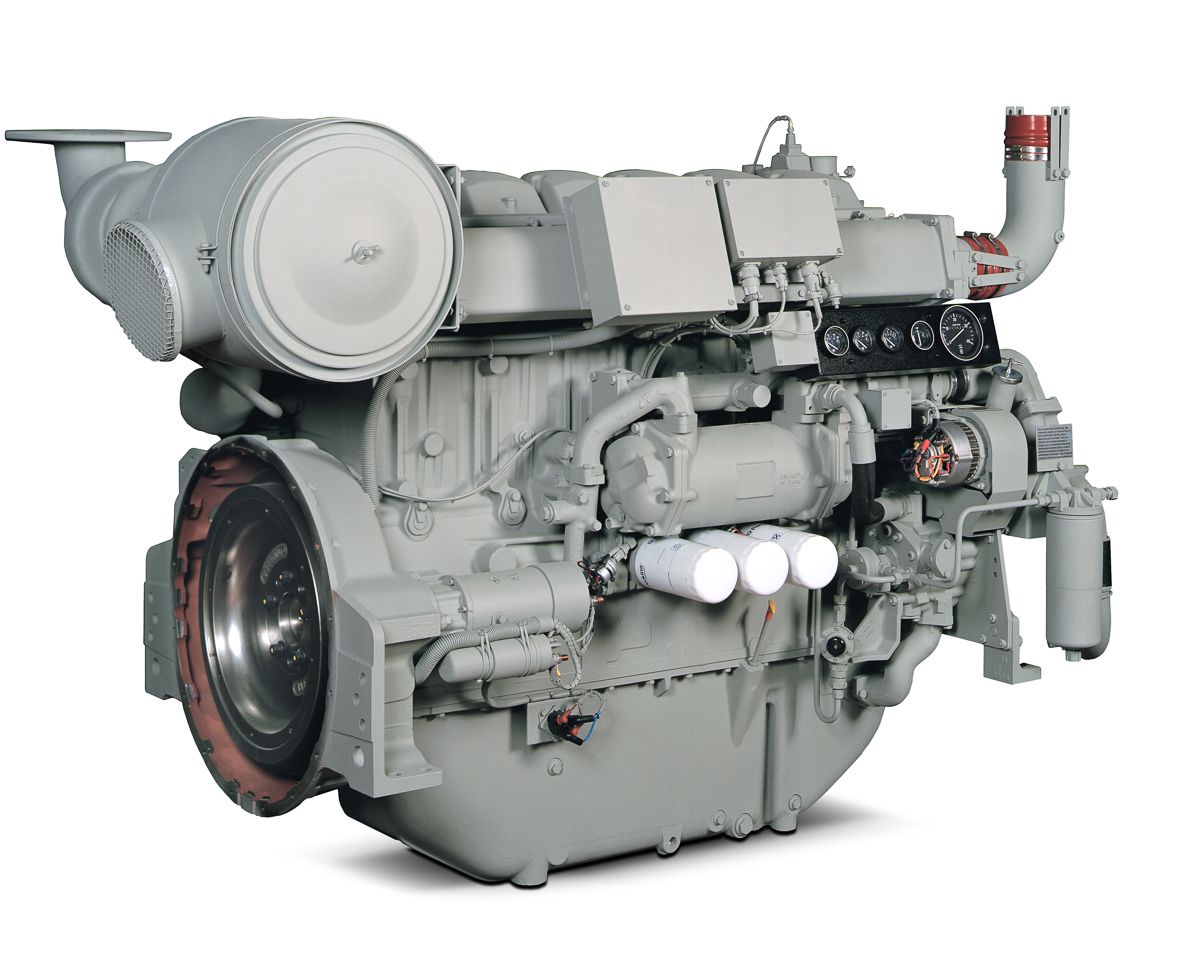

The 6 cylinder Perkins 4006 range gives you the versatility you need in today's power generation market. The range's diesel ElectropaK engines/Electro Units deliver 750-900 kVA and are supplied with or without radiator and air cleaner. This engine has proven reliability in prime and standby installations in all of the key sectors, such as manufacturing facilities, hospitals, and data centres. The 4006 engines have exceptional power-to-weight ratios and compact designs, making them simple to transport and install.

Designed to meet ½ TA Luft (1986) emission standardsSpecifications

| Gross Mechanical Output | 531-886 kWm |

| Typical Electrical Output | 595-1000 kVA (476-800 kWe) |

| Emissions | Fuel Optimised |

Benefits & Features

Dependable power

• Individual 4 valve cylinder heads giving optimised gas flows

• Unit fuel injectors ensure ultra fine fuel atomisation and hence controlled rapid combustion • Commonality of components with other engines in the 4000 Series family for reduced stocking levels • Capable emissions of 1/2 TA Luft (1986)Low operating costs

• Oil change service intervals are set at 500 hours as standard

• Designed to provide low cost of ownership, simple maintenance and reduced downtime • Class leading warranty. Prime power - 12 months unlimited hours. For engines that operate less than 6,000 hours the warranty is available for two years or until the application reaches 6,000 hours (whichever is sooner). Standby power - three years or 1,500 hours (whichever is sooner). • Perkins Platinum Protection - comprehensive cover from as little as 5 percent* of the cost of your engine. Talk to your local distributor or visit www.perkins.com/platinum protection for more detailsWorld class product support

• Our experienced global network of distributors and dealers, fully trained engine experts deliver total service support around the clock, 365 days a year. They have a comprehensive suite of web based tools at their disposal, covering technical information, parts identification and ordering systems, all dedicated to maximising the productivity of your engine

• Perkins actively pursues product support excellence by insisting our distribution network invest in their territory to provide customers with a consistent quality of support across the globe • Throughout the entire life of a Perkins engine, we provide access to genuine parts giving 100% reassurance that you receive the very best in terms of quality for lowest possible cost, wherever your Perkins powered machine is operating in the world. To find your local distributor: www.perkins.com/distributorSpecifications

| Gross Mechanical Output | 531-886 kWm |

| Typical Electrical Output | 595-1000 kVA (476-800 kWe) |

| Rated Speed | 1500/1800 rpm |

| Prime | 746-802 KVA |

| Standby | 820-898 KVA |

| Baseload | 595-637 kVA |

| Prime | 600-722 kWe |

| Standby | 660-800 kWe |

| Baseload | 480-572 kWe |

| Emissions | Fuel Optimised |

| Number of Cylinders | 6 inline |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Compression Ratio | 13.6:1 |

| Aspiration | Turbocharged and air-to-air charge cooled |

| Combustion System | Direct injection |

| Rotation from Flywheel End | Anti-clockwise |

| Cooling System | Liquid |

| Aftertreatment | - |

| Typical Alternator Efficiency | 90-95% |

| Switchable | Yes |

| Length | — |

| Width | — |

| Height | — |

| Dry Weight | — |

| Note 1 | *Final dimensions dependent on selected options |

| Prime Power | Unlimited hours usage with an average load factor of 80% of the published prime power over each 24 hours period. A 10% overload is available for |

| Standby Power | Limited to 500 hours annual usage with an average load factor of 80% of the published standby power rating over each 24 hour period. Up to 300 hours of annual usage may be run continuously. No overload is permitted on standby power. |

| Baseload | Unlimited hours usage with an average load factor of 100% of the published baseload power. No overload is permitted on baseload power. |

Benefits & Features

Dependable power

• Individual 4 valve cylinder heads giving optimised gas flows

• Unit fuel injectors ensure ultra fine fuel atomisation and hence controlled rapid combustion • Commonality of components with other engines in the 4000 Series family for reduced stocking levels • Capable emissions of 1/2 TA Luft (1986)Low operating costs

• Oil change service intervals are set at 500 hours as standard

• Designed to provide low cost of ownership, simple maintenance and reduced downtime • Class leading warranty. Prime power - 12 months unlimited hours. For engines that operate less than 6,000 hours the warranty is available for two years or until the application reaches 6,000 hours (whichever is sooner). Standby power - three years or 1,500 hours (whichever is sooner). • Perkins Platinum Protection - comprehensive cover from as little as 5 percent* of the cost of your engine. Talk to your local distributor or visit www.perkins.com/platinum protection for more detailsWorld class product support

• Our experienced global network of distributors and dealers, fully trained engine experts deliver total service support around the clock, 365 days a year. They have a comprehensive suite of web based tools at their disposal, covering technical information, parts identification and ordering systems, all dedicated to maximising the productivity of your engine

• Perkins actively pursues product support excellence by insisting our distribution network invest in their territory to provide customers with a consistent quality of support across the globe • Throughout the entire life of a Perkins engine, we provide access to genuine parts giving 100% reassurance that you receive the very best in terms of quality for lowest possible cost, wherever your Perkins powered machine is operating in the world. To find your local distributor: www.perkins.com/distributorData not available.

Standard Equipment

- Air inlet system

- Mounted air filter and turbocharger

- Cooling system

- Radiator supplied loose incorporating air-to-air charge cooler

- System designed for ambients up to 50ºC (122ºF)

- Twin thermostats, water pump

- Electrical equipment

- 24V starter motor, 24V alternator with integral voltage regulator and DC output

- High coolant temperature protection switch

- Low oil pressure protection switch

- Turbine inlet temperature protection

- Flywheel and housing

- SAE ‘0' flywheel housing

- SAE J620 size 18 flywheel

- Fuel system

- Digital governing to ISO 8528-5 Class G2 with isochronous capability

- Direct fuel injection system with fuel lift pump

- Full flow spin-on filters

- Lubrication system

- Full flow spin-on oil filters

- Wet full aluminium sump with filler and dipstick

- Optional equipment

- 4 meter wiring harness

- Exhaust counter flanges

- Immersion heater

- Secondary electric start

- Single exhaust outlet pipe

- Temperate radiator kit