Overview

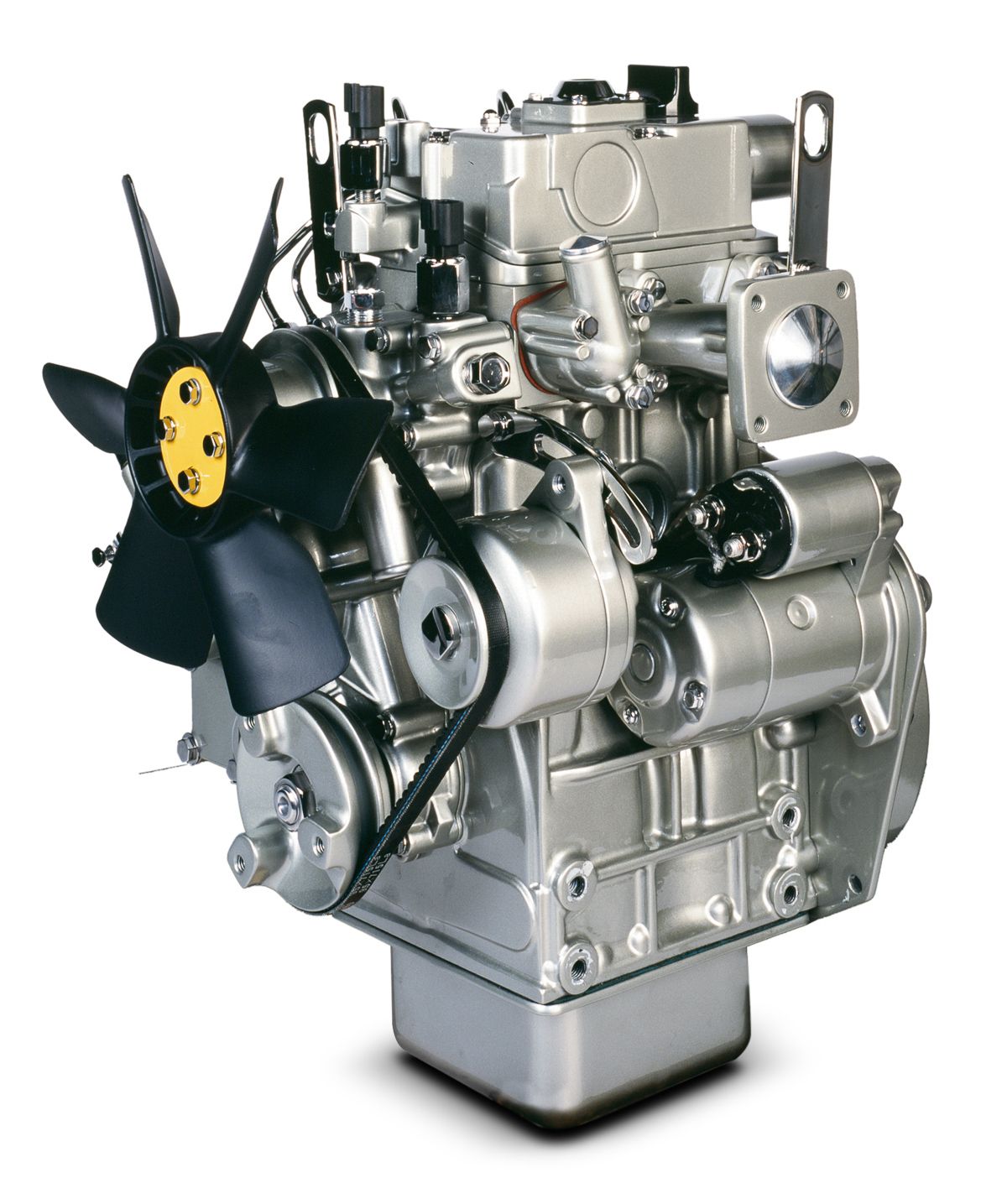

Perkins 400 Series electric power (EP) engines are the ideal solution if you're looking for reliable, economical power from a compact unit. Our 402 range is the smallest of all. These 0.5 litre, 2 cylinder engines are robust and efficient and can fulfil your power generation needs with minimal operating costs. Engines meet EU Stage IIIA/U.S. EPA Tier 4 interim and the more stringent Tier 4 Final emissions standards. Impressive cold-start capabilities even in the most demanding conditions make them an excellent choice for less regulated territories.

The 402D-05G is a naturally aspirated, indirect injection engine that meets EU Stage IIIA/U.S. EPA Tier 4 interim emissions standards.Specifications

| Gross Mechanical Output | 4.6-5.1 kWm |

| Typical Electrical Output | 4.8-5.3 kVA (3.9-4.2 kWe) |

| Emissions | EU Stage IIIA/U.S. EPA Tier 3 |

Benefits & Features

Lower operating costs

The durability of the 402 range, its simple technology, ease of installation and warranty offering all combine to drive down your ownership costs. Oil and filter changes are 500 hours, dependent on load factor, which also trims your costs. As the 400 Series is built on a common engine platform, if you need to upgrade you can do so easily and affordably.

Small packages

When you need power and reliability in even the smallest application, you can trust the 400 Series EP engines to deliver. Our engineers have carefully designed every component to minimise space. Your engine can also be flexibly adapted to make installation and servicing even easier.

Specifications

| Gross Mechanical Output | 4.6-5.1 kWm |

| Typical Electrical Output | 4.8-5.3 kVA (3.9-4.2 kWe) |

| Rated Speed | 1800 rpm |

| Prime | 3.9 kWe |

| Standby | 4.2 kWe |

| Emissions | EU Stage IIIA/U.S. EPA Tier 3 |

| Number of Cylinders | 2 inline |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Compression Ratio | 23.5:1 |

| Aspiration | Naturally aspirated |

| Combustion System | Indirect injection |

| Rotation from Flywheel End | Anti-clockwise |

| Cooling System | Liquid |

| Aftertreatment | - |

| Typical Alternator Efficiency | 84.70% |

| Switchable | No |

| Length | — |

| Width | — |

| Height | — |

| Dry Weight | — |

| Note 1 | *Final dimensions dependent on selected options |

| Note 2 | ESE (1800 rpm) only - Emergency Stationary Equipment |

| Prime Power | Power available at variable load in lieu of a main power network. Overload of 10% is permitted for one hour in every 12 hours of operation. |

| Standby Power | Power available at variable load in the event of a main power network failure. No overload is permitted. |

Benefits & Features

Lower operating costs

The durability of the 402 range, its simple technology, ease of installation and warranty offering all combine to drive down your ownership costs. Oil and filter changes are 500 hours, dependent on load factor, which also trims your costs. As the 400 Series is built on a common engine platform, if you need to upgrade you can do so easily and affordably.

Small packages

When you need power and reliability in even the smallest application, you can trust the 400 Series EP engines to deliver. Our engineers have carefully designed every component to minimise space. Your engine can also be flexibly adapted to make installation and servicing even easier.

Data not available.

Standard Equipment

- Air inlet system

- Mounted air filter

- Control system

- 12 volt electronic shut off solenoid (ESOS) energised to run

- 12 volt starter motor and 12 volt 14 amp alternator with DC output

- Glow plug cold start aid and heater/starter switch

- Oil pressure and coolant temperature switches

- Cooling system

- Thermostatically-controlled system with belt driven coolant pump and pusher fan

- Radiator and hoses supplied separately

- Flywheel and flywheel housing

- 1500/1800 rpm High inertia flywheel to SAE J620 Size 6½ Heavy Flywheel housing SAE 5 Long

- 3000 rpm High inertia flywheel to SAE J620 Size 6½ Light Flywheel housing SAE 5 Short

- Fuel system

- Mechanically governed cassette type fuel injection pump

- Split element fuel filter

- Oil system

- Wet steel sump with filler and dipstick

- Spin-on full-flow lubricating oil filter