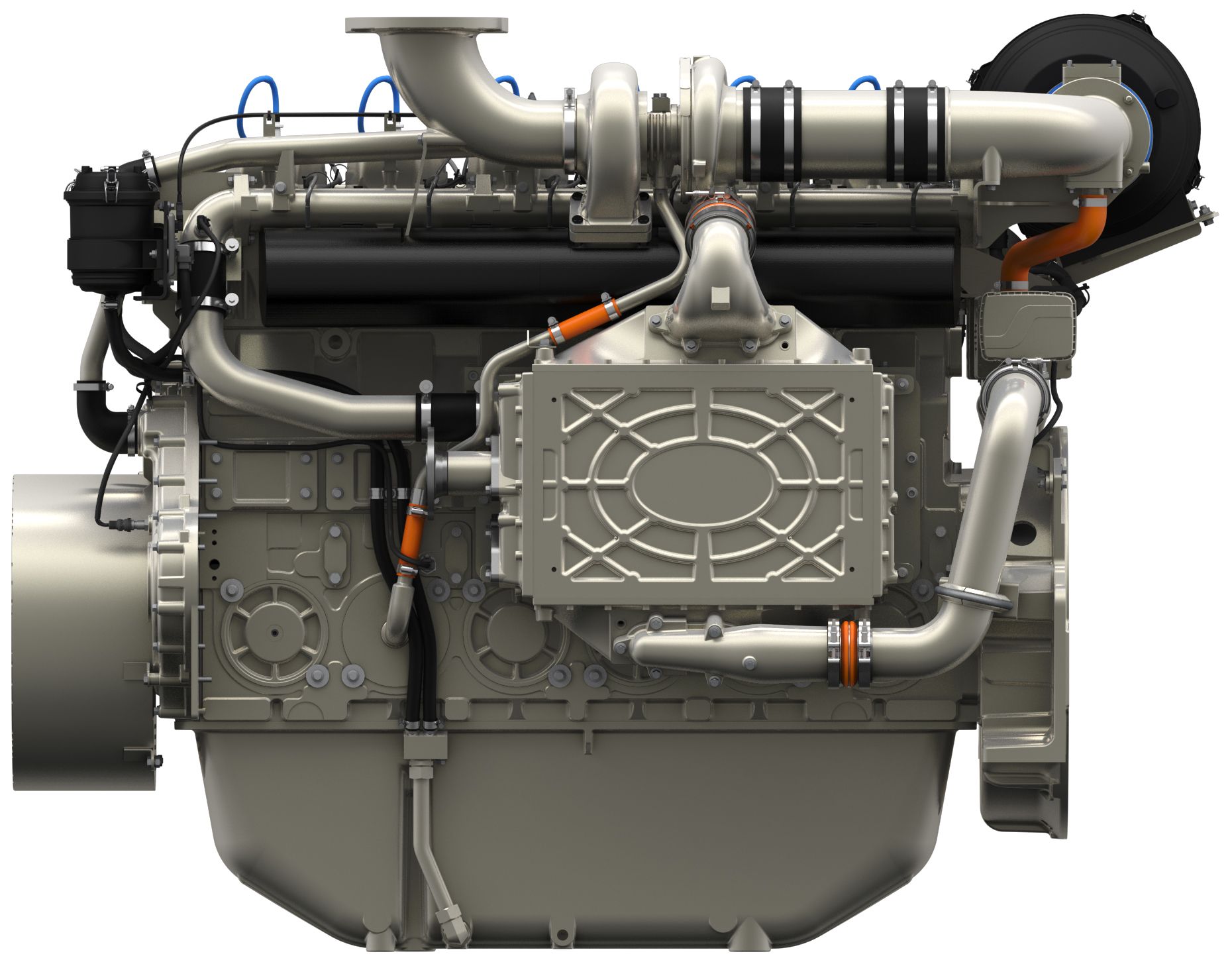

4006-E23TRS Spark Ignited Gas EngineNon-Current

4006-E23TRSOverview

The 4006-E23TRS 6-cylinder spark ignition gas engine offers high performance, dependability and reliability whilst meeting the market’s increasingly stringent emission requirements. The 4006-E23TRS is a turbocharged, air to water charge cooled, 6 cylinder inline engine, designed for operation on a wide range of methane based gases.

Specifications

| Mechanical Output | 322/423 kWm |

| Electrical Output | 310/408 kWe |

| Emissions | This engine does not comply to Harmonised International Regulated Emissions Limits |

Benefits & Features

Economic power

Utilises advanced combustion technology to deliver durable and reliable power

• High commonality of components with other engines in the 4000 Series family for reduced stocking levels • Individual large valve cylinder heads with matched deep bowl pistons for greater swirl, achieve high mechanical efficiencyReliable power

Developed and tested using the latest engineering techniques

• Piston temperatures controlled by an advanced gallery jet cooling system • Extended durability and attention to reducing servicing with extended component life add benefit of the reduced whole life cost • Robust to varying gas qualityCompact, clean and efficient power

Exceptional power-to-weight ratio and compact size give optimum power density for ease of transportation and installation

• In excess of 40% mechanical efficiency • Designed to provide excellent service access for ease of maintenance • All engines in the 4000 Series family are capable of meeting the NOx requirements of TA LuftSpecifications

| Emissions | This engine does not comply to Harmonised International Regulated Emissions Limits |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Aspiration | Turbocharged and air-to-water charge cooled |

| Rotation from Flywheel End | Anti-clockwise |

| Compression Ratio | 14:01 |

| Number of Cylinders | 6 inline |

| Combustion System | Spark ignited |

| Cooling System | Liquid |

| Height - Engine Only Dimension | — |

| Dry Weight - Engine Only | — |

| Length - Engine Only Dimension | — |

| Width - Engine Only Dimension | — |

| Mechanical Output | 322/423 kWm |

| Electrical Output | 310/408 kWe |

| Rated Speed | 1500 rpm |

| Height | — |

| Length | — |

| Dry Weight | — |

| Width | — |

Benefits & Features

Economic power

Utilises advanced combustion technology to deliver durable and reliable power

• High commonality of components with other engines in the 4000 Series family for reduced stocking levels • Individual large valve cylinder heads with matched deep bowl pistons for greater swirl, achieve high mechanical efficiencyReliable power

Developed and tested using the latest engineering techniques

• Piston temperatures controlled by an advanced gallery jet cooling system • Extended durability and attention to reducing servicing with extended component life add benefit of the reduced whole life cost • Robust to varying gas qualityCompact, clean and efficient power

Exceptional power-to-weight ratio and compact size give optimum power density for ease of transportation and installation

• In excess of 40% mechanical efficiency • Designed to provide excellent service access for ease of maintenance • All engines in the 4000 Series family are capable of meeting the NOx requirements of TA LuftData not available.

Standard Equipment

- Air inlet system

- Dry exhaust manifolds

- Exhaust manifold sheilding

- High efficiency turbocharger

- Mounted air filter - replaceable cartridge type

- Upgraded air filters � Powercore Filter for improved component life

- Electrical equipment

- 24 volt starter motor

- High coolant temperature switch

- Low oil pressure switch

- High manifold pressure switch

- Digital knock detection

- Cooling system

- Air to water charge cooler, pipe work – supply on Electro Unit only

- Jacket water thermostatic control – supply on Electro Unit only

- Pressurised jacket water cooling system, gear-driven jacket water, circulating pump – supply on Electro Unit only

- Flywheel and flywheel housing

- High inertia flywheel to SAE J620 size 18

- SAE ‘0' flywheel housing

- General

- Front and rear engine mounting support

- Governing, gas and ignition system

- Air/fuel mixer with zero pressure regulator and mixture adjustment screw

- Woodward L-ECM Series ignition system with individual cylinder ignition coils, spark plugs

- Digital governing system, governing to ISO8528-5 class G2

- Metal braided flexible gas connection

- Oil system

- Closed circuit crankcase ventilation system – natural gases only

- Full flow replaceable canister type oil filters

- Gear driven, externally mounted lubricating oil pump

- Jacket water cooled shell and tube oil cooler/stabiliser

- Low oil pressure switch

- Wet sump with filler and dipstick