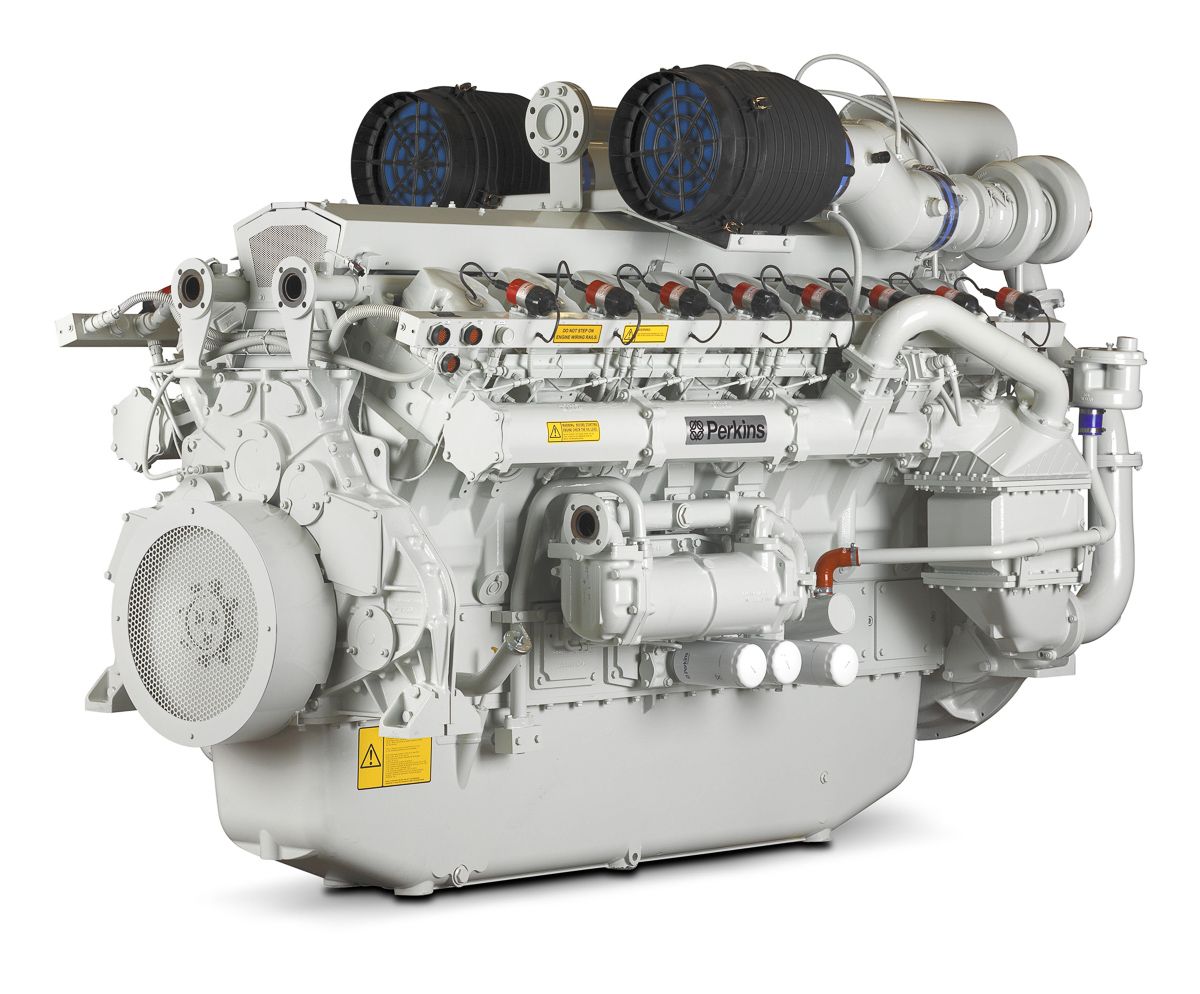

4016-61TRS Spark Ignited Gas EngineNon-Current

4016-61TRSOverview

The Perkins 4000 Series gas engines give you the versatility you need for today's power generation market. They deliver the same high efficiency performance as their diesel counterparts and meet increasingly stringent emissions standards. They can run on landfill gas, digester gas, biogas and coal-bed mine gas and, with exceptional power-to-weight ratios and compact design, they are easy to transport and install.

Capable of meeting the NOx requirements of TA Luft.Specifications

| Mechanical Output | 912-1042 kWm |

| Electrical Output | 875-1000 kWe |

| Emissions | This engine does not comply to Harmonised International Regulated Emissions Limits |

Benefits & Features

Optional equipment

Options for your 4000 Series gas engines include:

• AFR controller (depending on gas quality, variability) • 220/240 volt thermostatically controlled immersion heater • Three-way thermostatic valve for charge cooler cooling circuit • Mechanically driven water pump for charge cooler circuit • Exhaust temperature monitoringUnderstanding your need

Our commitment to excellence goes far beyond the engine itself. Through our 4000 Series Gas Centres of Excellence, we build strong and trusted relationships with you. Not only do our Centres of Excellence distributors keep your engine running in peak condition, they also have an in-depth knowledge of power generation in your market.

They understand your environment, your local emissions standards and the reliability of your grid. And they know what works for your specific circumstances.Wide range of methane-based gases

Gas engines in the series are up to 61.12 litres, with both inline and vee form designs and from 6-16 cylinders.

Engines can be fuelled by a wide range of methane-based gases, including landfill gas, digester gas, biogas and coal bed mine gas.Specifications

| Mechanical Output | 912-1042 kWm |

| Electrical Output | 875-1000 kWe |

| Rated Speed | 1500 rpm |

| Emissions | This engine does not comply to Harmonised International Regulated Emissions Limits |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Aspiration | Turbocharged and air-to-water charge cooled |

| Rotation from Flywheel End | Anti-clockwise |

| Number of Cylinders | 16 vee |

| Compression Ratio | 12:1 |

| Combustion System | Spark ignited |

| Cooling System | Liquid |

| Dry Weight | — |

| Height | — |

| Width | — |

| Length | — |

| Note 1 | Final weight and dimensions will depend on completed specification |

Benefits & Features

Optional equipment

Options for your 4000 Series gas engines include:

• AFR controller (depending on gas quality, variability) • 220/240 volt thermostatically controlled immersion heater • Three-way thermostatic valve for charge cooler cooling circuit • Mechanically driven water pump for charge cooler circuit • Exhaust temperature monitoringUnderstanding your need

Our commitment to excellence goes far beyond the engine itself. Through our 4000 Series Gas Centres of Excellence, we build strong and trusted relationships with you. Not only do our Centres of Excellence distributors keep your engine running in peak condition, they also have an in-depth knowledge of power generation in your market.

They understand your environment, your local emissions standards and the reliability of your grid. And they know what works for your specific circumstances.Wide range of methane-based gases

Gas engines in the series are up to 61.12 litres, with both inline and vee form designs and from 6-16 cylinders.

Engines can be fuelled by a wide range of methane-based gases, including landfill gas, digester gas, biogas and coal bed mine gas.Data not available.

Standard Equipment

- Air inlet system

- Dry cast iron exhaust manifolds with heat shields

- Exhaust gas driven turbocharger

- Horizontal exhaust outlet

- Paper element air filter complete with restriction indicator

- Control system

- 24 volt starter motor

- Cooling system

- Pressurised jacket water cooling system

- Two stage air-to-water charge cooler, jacket/secondary water cooled

- Core engine

- Aluminium alloy piston with advanced bowl design. Three ring pack, gallery (oil) cooled

- Crankshaft driven gear train for camshaft

- Forged camshaft – carburised hardened

- Forged steel crankshaft

- High grade cast iron featuring integral crankcase inspection doors

- High grade cast iron individual cylinder heads, each with four valves per cylinder

- Split cap connecting rods, forged steel with multi-bolt fixing – shot peened

- Wet type liners in centrifugal cast iron, plateau honed for quick ring bedding and reduced oil consumption

- Flywheel and flywheel housing

- Cast iron flywheel housing SAE 00 and flywheel SAE J620 Size 18

- Viscous type torsional vibration damper

- General

- All engines are preserved after test running, shrink wrapping and suitable for containerised shipment

- Commercial primer finish

- Engine supports: front and rear feet mounted off the crankcase

- Governing, gas and ignition system

- Air/Fuel mixer with Heinzmann Elektra gas injection valve control system; automatic adjustment according to fuel gas characteristics

- Engine protection system for high/low coolant temperature and low oil pressure, overspeed, misfire and knock protection

- Full electronic management system, governing to ISO 8528 Part 5 Class G2 standard

- Individual cylinder ignition coils mounted direct to the spark plugs

- Oil system

- Crankcase closed circuit ventilation system

- Gear driven, externally mounted lubricating oil pump

- Jacket water cooled shell and tube oil coolers

- Spin-on, canister type replaceable lubricating oil filters