Overview

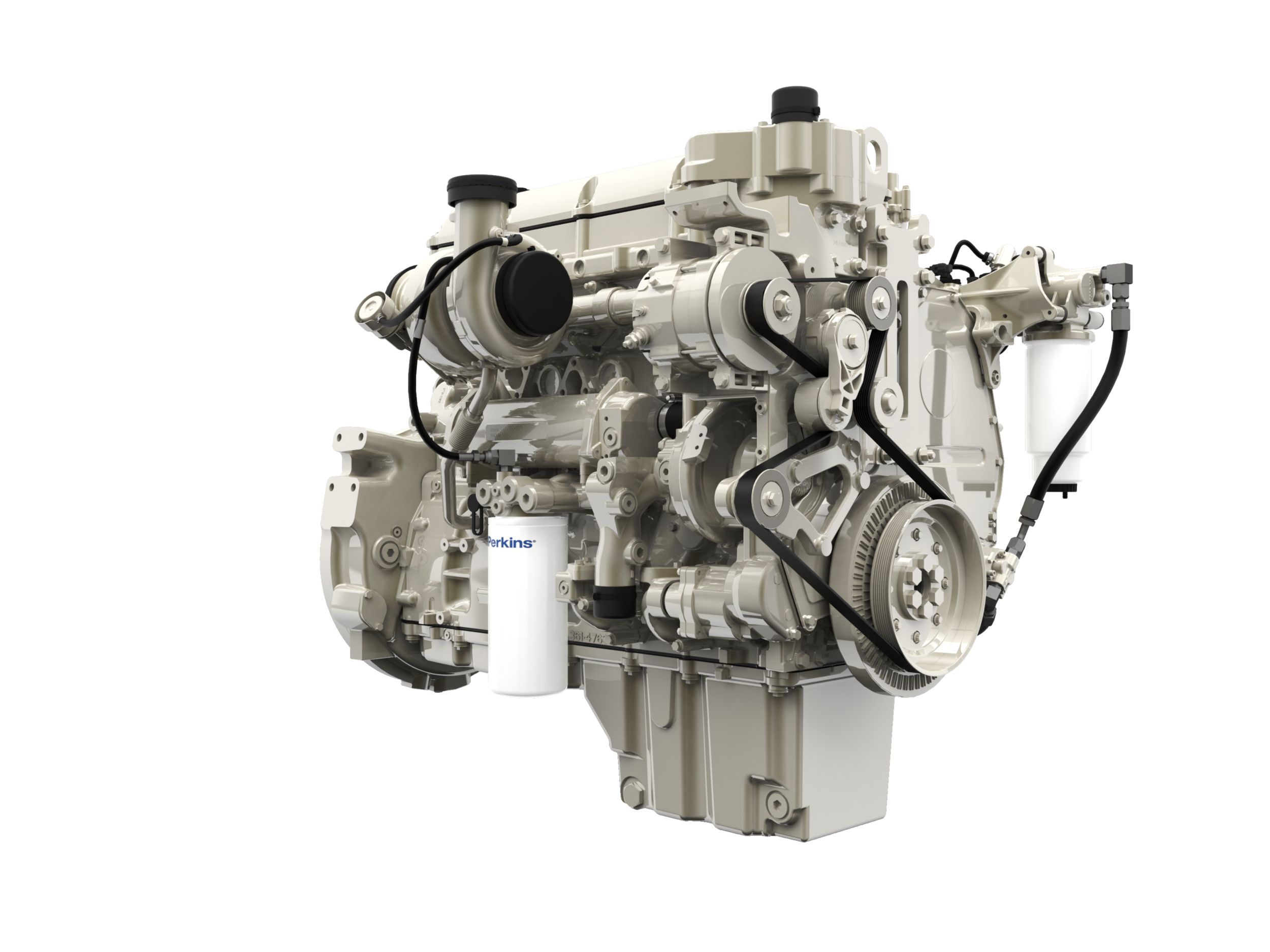

The 2406J/EA-E13TA is a 6 cylinder, 12.5 litre engine capable of producing up to 430 kW (577 hp) of power and 2634 Nm (1943 lb-ft) of torque out of a compact, lightweight package. The 2406J-E13TA is certified to EU Stage V/U.S. EPA Tier 4 Final, along with Japan 2014 (Tier 4 Final) and Korea Stage V. The 2406EA-E13TA is certified to China Nonroad (NR) Stage IV. This simplifies the decision-making process for global customers by allowing them to standardise their worldwide product offering and reap the benefits of common installation, maintenance and service requirements from a single supplier solution.

Specifications

| Maximum Power | — |

| Maximum Torque | — |

| Emissions | China NR IV |

Benefits & Features

High power density and torque

A 6 cylinder, 12.5 litre engine with power up to 430 Nm and peak torque of 2640 Nm to enable engine downsizing.

Low cost of ownership

Optimised design across all systems – fuel, air, electrical, thermal – driving efficiency and lowering total fluid consumption.

Innovative solutions

Perkins design technology and high-efficiency SCR enable a compact, lightweight aftertreatment with simple installation requirements.

Specifications

| Maximum Power | — |

| Maximum Torque | — |

| Rated Speed | 1800-2100 rpm |

| Minimum Power | — |

| Emissions | China NR IV |

| Number of Cylinders | 6 inline |

| Cycle | 4 stroke |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Compression Ratio | 15.8:1 |

| Aspiration | Turbocharged aftercooled |

| Combustion System | Direct injection |

| Rotation from Flywheel End | Anti-clockwise |

| Aftertreatment | DOC+DPF+SCR |

| Cooling System | Liquid |

| Length | — |

| Width | — |

| Height | — |

| Dry Weight | — |

| Note 1 | *Final dimensions dependent on selected options |

Benefits & Features

High power density and torque

A 6 cylinder, 12.5 litre engine with power up to 430 Nm and peak torque of 2640 Nm to enable engine downsizing.

Low cost of ownership

Optimised design across all systems – fuel, air, electrical, thermal – driving efficiency and lowering total fluid consumption.

Innovative solutions

Perkins design technology and high-efficiency SCR enable a compact, lightweight aftertreatment with simple installation requirements.

Maximum uptime

Thermal management designed to provide transparent regeneration, without distraction to the operator or impact to machine performance.

Low installation costs

Fully configurable product with factory solutions such as engine mounted aftertreatment and full power units to limit installation complexity.

The 2406J will be available in single label certification for EU Stage V, U.S. EPA Tier 4 Final, Japan 2014 and Korea Tier 4 Final providing global customers a single source solution that streamlines design, installation and service processes.

Data not available.

Standard Equipment

- Aftertreatment Equipment

- SCR Auxiliaries - A range of tanks and heated lines are available

- Air System

- Turbocharged aftercooled

- Electrical and Electronics

- All connectors and wiring looms waterproof and designed to withstand harsh off-highway environments

- Flexible and configurable software features and well supported SAE J1939 CAN bus enables highly integrated machines

- Full electronic control system with all system functions controlled from a single, engine-mounted electronic control module

- Cooling System

- Detailed guidance on cooling system design and validation available to ensure machine reliability

- Vertical outlet thermostat housing, centifugal water pump

- Flywheel and Flywheel Housing

- Wide choice of drivetrain interfaces, SAE1 configurations

- Fuel System

- Mechanical Unit Injector fuel system, controlled electronically

- Industrial technology requires Ultra Low Sulphur Diesel fuel (ULSD, 15 ppm sulphur), in addition to ultra low sulphur diesel oils, for use in Tier 4 Final/Stage V engines. These cleaner fuels and oils will help reduce ash and maintain service intervals. In addition, B20 biodiesel capability adds even greater sustainability where desired or required

- Oil System

- Choice of sumps for different applications

- Oil cooler, oil filler, oil filter, oil dipstick, oil pump (gear-driven)

- Open crankcase ventilation system with fumes disposal (OCV filter option required for EU Stage V certification engines)

- Power Take-Off (PTO)

- Engine power can also be taken from the front of the engine on some applications

- SAE1 power take-off available with optional SAE B and SAE C power take-off drives (dual rear)