Overview

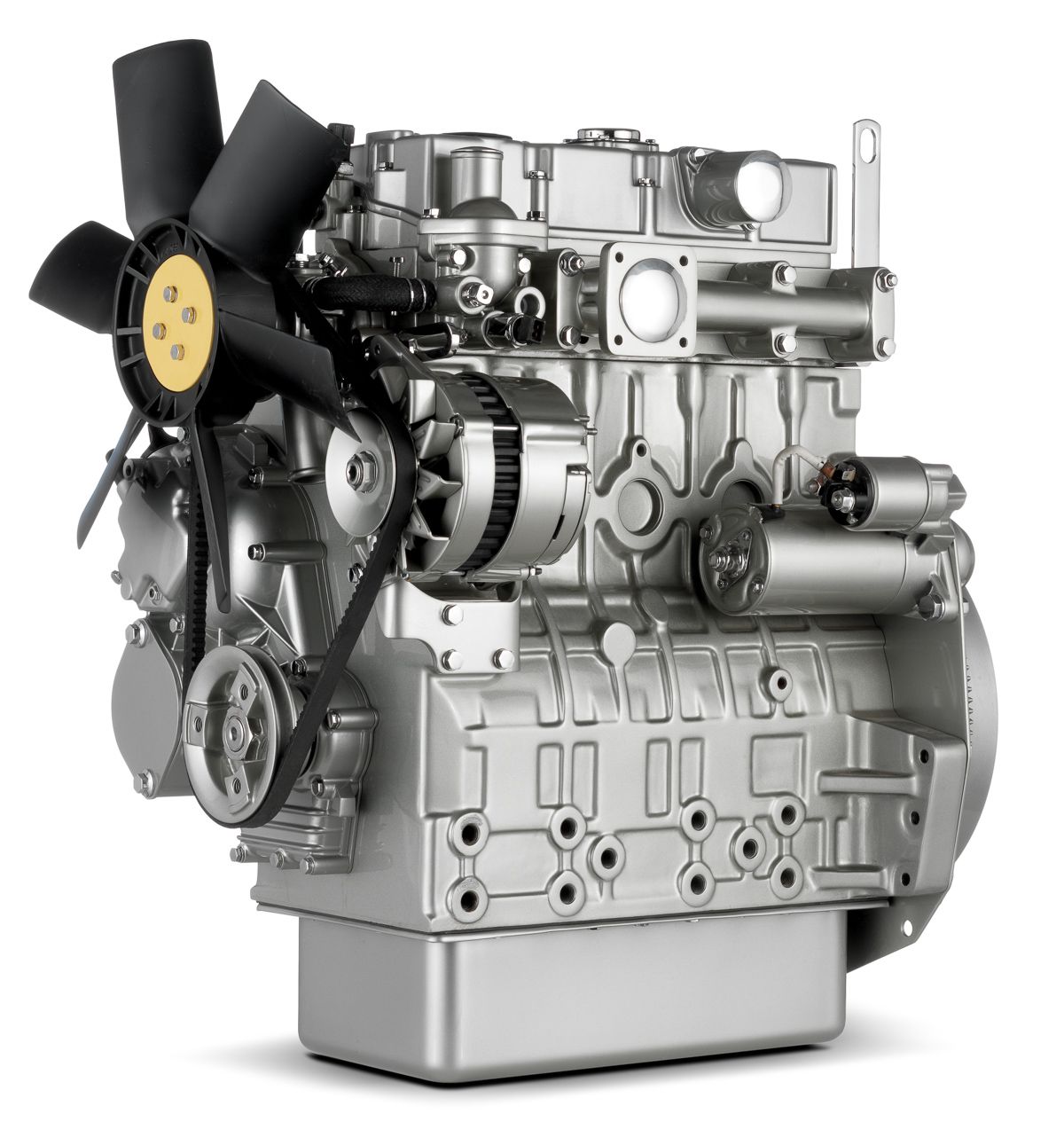

The 404EA-22 and 404EA-22T are indirect injection industrial diesel engines meeting China offroad NR4 without the need for electronic control, aftertreatment or exhaust gas recirculation. Available as naturally aspirated or turbocharged for improved low speed torque, we also offer a range of factory configurable options to minimise the cost of machine development and of manufacturing if equiped with e-controller.

Specifications

| Maximum Power | — |

| Maximum Torque | — |

| Emissions | China NR IV |

Benefits & Features

Durable power

The Perkins 400 Series has been proven to deliver durable power. Manufactured in highly automated, state-of-the-art production facilities, a wide range of customisation is available while preserving high quality levels.

Tailored for your machines

The compact design of these engines makes them suitable for a range of applications, including skid steer loaders, mini excavators, wheel loaders, welders, lift platforms, lighting towers, small tractors, air compressors, turf care machinery and materials handling machinery.

Each of the six core engines in the 400 Series is configured for either Stage IIIA/Tier 4 Interim or Stage IIIB/Tier 4 Final emission standards, giving you flexibility depending on your market.Quiet in service

The stiff block and indirect injection system make this a quiet engine, minimising operator fatigue and saving costs for OEMs in sound attenuation measures.

Specifications

| Maximum Power | — |

| Maximum Torque | — |

| Rated Speed | 2800 rpm |

| Minimum Power | — |

| Emissions | China NR IV |

| Number of Cylinders | 4 inline |

| Cycle | 4 stroke |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Compression Ratio | 23.3:1 |

| Aspiration | Naturally aspirated |

| Combustion System | Indirect injection |

| Rotation from Flywheel End | Anti-clockwise |

| Aftertreatment | - |

| Cooling System | Liquid |

| Length | — |

| Width | — |

| Height | — |

| Dry Weight | — |

| Note 1 | *Final dimensions dependent on selected options |

Benefits & Features

Durable power

The Perkins 400 Series has been proven to deliver durable power. Manufactured in highly automated, state-of-the-art production facilities, a wide range of customisation is available while preserving high quality levels.

Tailored for your machines

The compact design of these engines makes them suitable for a range of applications, including skid steer loaders, mini excavators, wheel loaders, welders, lift platforms, lighting towers, small tractors, air compressors, turf care machinery and materials handling machinery.

Each of the six core engines in the 400 Series is configured for either Stage IIIA/Tier 4 Interim or Stage IIIB/Tier 4 Final emission standards, giving you flexibility depending on your market.Quiet in service

The stiff block and indirect injection system make this a quiet engine, minimising operator fatigue and saving costs for OEMs in sound attenuation measures.

Data not available.

Standard Equipment

- Cooling System

- Coolant temperature switch

- High and low cooling fan positions

- Electrical and Electronics

- Alternator 12V, 40, 65 and 85 Amp

- Starter motor 12V, 2.0 kW

- Electronic Shut Off Solenoid (ESOS)

- Glow plug starting aid

- Flywheel and Flywheel Housing

- Flywheel Housing SAE 4

- Flywheel SAE 7 1/2 and SAE 8/10

- Fuel System

- CTD fuel injection pump

- Spin-on fuel filter

- General

- Gradeability 35° continuous

- Oil System

- Lubricating oil pressure switch

- Spin-on lubricating oil filter

- Dipstick options available

- Power Take-Off (PTO)

- SAE A PTO