Overview

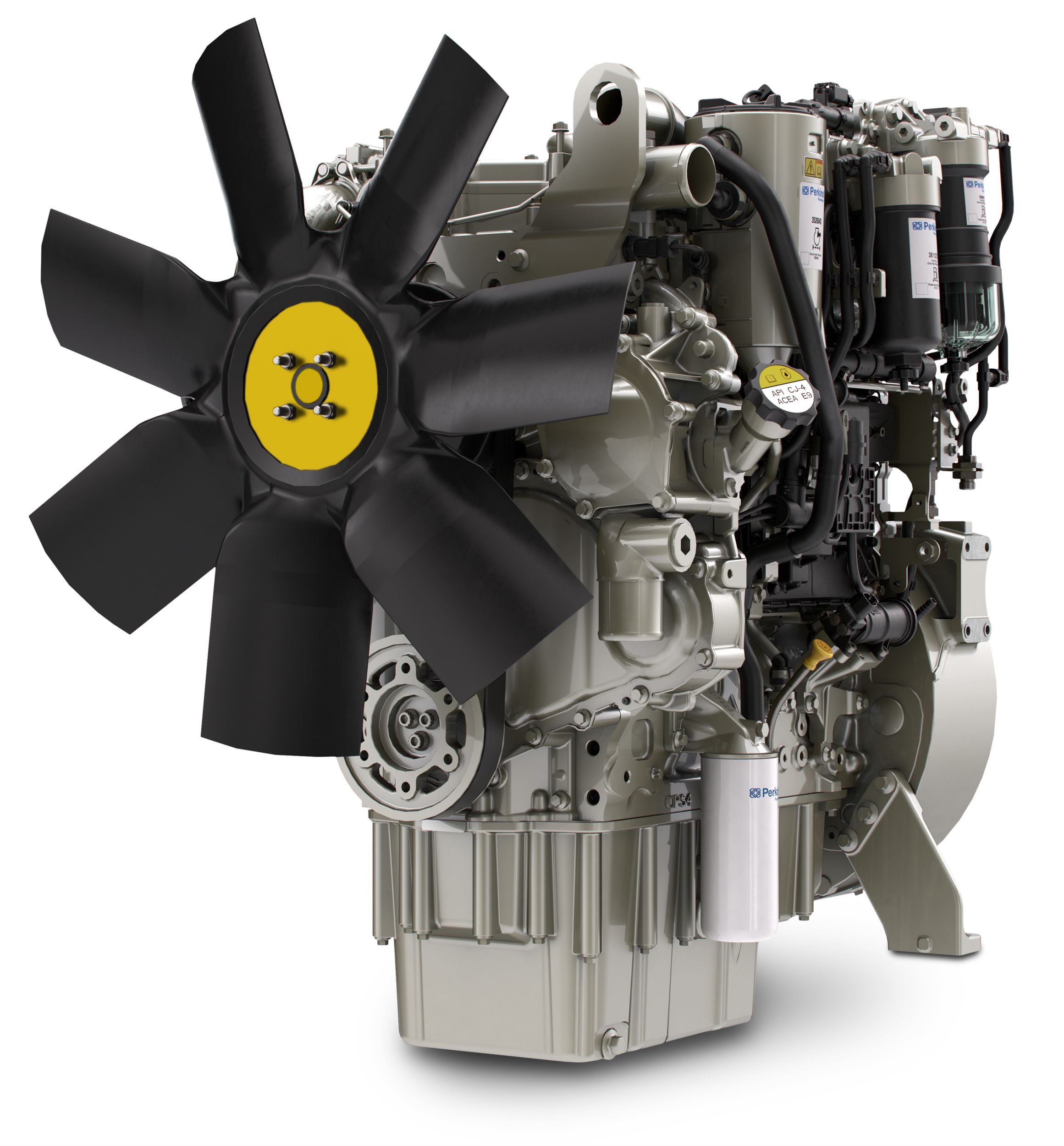

The Perkins® 1204D, the 4 cylinder option for the 1200 Series that gives you a complete power solution for UN ECE R96 Stage IIIA/Brazil Mar 1 emission standards. The choice of options, engine configurations and robust technology allows you to integrate the 1204 range into your equipment with minimum engineering.

Specifications

| Maximum Power | — |

| Maximum Torque | — |

| Emissions | UN ECE R96 Stage IIIA, Brazil Mar-1 |

Benefits & Features

A lifetime of low cost

We have designed the Perkins®1204 range with optimised fuel consumption in mind, matching it to the operating cycles of a wide range of equipment and applications. Low cost maintenance is achieved through hydraulic tappets, multi-vee belts,

service free aftertreatment and 500 hour oil change intervals. In addition, on the 1204D industrial engine, many service items can be located on either side of the engine to give you maximum access for servicing.

Downsizing opportunity

The high power density and excellent torque in our 1204 range allows you to select a more compact engine where previously you might have used an engine of a higher cubic capacity. This downsizing has several benefits, including saving you money

and providing more space to package aftertreatment units.

Tailored for your machines

Your needs are our top priority, which is why we provide more tailored technology than anyone else. Working closely with OEMs, we have developed the 1204 range with hundreds of options so that it easily fits into your machine.

Our 1204 range engines come with two year warranties as standard and can als be supported by extended service contracts.

Specifications

| Maximum Power | — |

| Maximum Torque | — |

| Rated Speed | 2200 rpm |

| Minimum Power | — |

| Emissions | UN ECE R96 Stage IIIA, Brazil Mar-1 |

| Number of Cylinders | 4 inline |

| Cycle | 4 stroke |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Compression Ratio | 16.5:1 |

| Aspiration | Series turbocharged aftercooled |

| Combustion System | Direct injection |

| Rotation from Flywheel End | Anti-clockwise |

| Aftertreatment | - |

| Cooling System | Liquid |

| Length | — |

| Width | — |

| Height | — |

| Dry Weight | — |

| Note 1 | *Final dimensions dependent on selected options |

Benefits & Features

A lifetime of low cost

We have designed the Perkins®1204 range with optimised fuel consumption in mind, matching it to the operating cycles of a wide range of equipment and applications. Low cost maintenance is achieved through hydraulic tappets, multi-vee belts,

service free aftertreatment and 500 hour oil change intervals. In addition, on the 1204D industrial engine, many service items can be located on either side of the engine to give you maximum access for servicing.

Downsizing opportunity

The high power density and excellent torque in our 1204 range allows you to select a more compact engine where previously you might have used an engine of a higher cubic capacity. This downsizing has several benefits, including saving you money

and providing more space to package aftertreatment units.

Tailored for your machines

Your needs are our top priority, which is why we provide more tailored technology than anyone else. Working closely with OEMs, we have developed the 1204 range with hundreds of options so that it easily fits into your machine.

Our 1204 range engines come with two year warranties as standard and can als be supported by extended service contracts.

Data not available.

Standard Equipment

- Air System

- Standard air cleaners

- Electrical and Electronics

- Flexible and configurable software features and well-supported SAE J1939 CAN bus enables highly integrated machines

- Full electronic control system, all connectors and wiring looms waterproof and designed to withstand harsh off-highway environments

- Cooling System

- 50:50 water glycol mix

- Detailed guidance on cooling system design and validation available to ensure machine reliability

- Top tank temperature 108°C (226°F) as standard to minimize cooling pack size

- Flywheel and Flywheel Housing

- Wide choice of drivetrain interfaces, including SAE No. 2 and SAE No. 3 configurations

- Fuel System

- Electronic high pressure common rail

- Innovative filter design to ensure maximum protection of the engine

- General

- Available with or without a balancer

- Oil System

- Wide choice of sumps for different applications

- Power Take-Off (PTO)

- SAE A and SAE B flanges on left-hand side. Additional SAE A flange available on left-hand side. Engine power can also be taken from the front of the engine on some applications. Factory fitted compressors are also available.