Overview

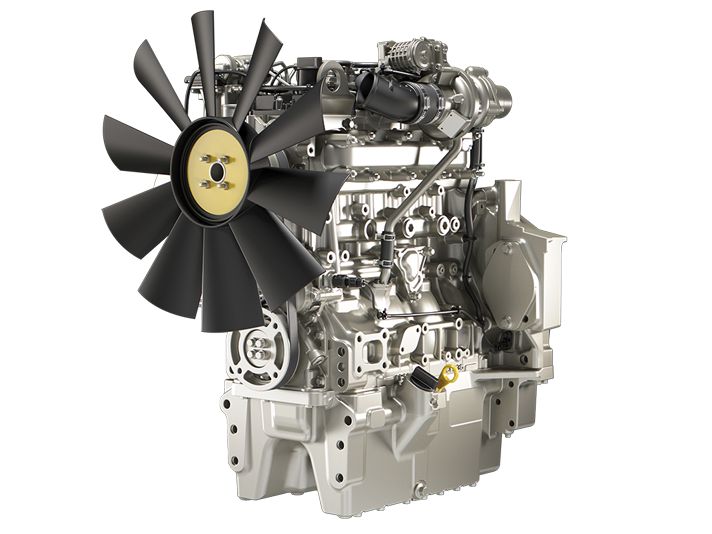

The 904 Series, 3.6 engine offers the perfect solution for frameless agricultural tractors - compact, powerful and quiet. Compact packaging including structural capability for front bolster and rear transmission, including twin balancers for operator comfort and rigid mounting; the 3.6 is the cornerstone of your tractor.

Our compact engine packaging enables tight turning circles and uninterrupted sight lines with no aftertreatment required and no A-Pillar or battery box interference; the 904 Series enables simple integration and easy logistics for the original equipment manufacturer.

Powerful, with excellent performance in power, peak and low speed torque, fuel consumption and transient response; the 3.6 has all the performance required including for downsizing from larger displacement engines for your tractor and your customers.

A naturally quiet engine by design, your customers will be impressed with the noise and sound quality of the engine, making the 3.6 a natural choice for tractors used around livestock and noise sensitive areas.Meets UN R96 (equivalent to EU Stage IIIA). Brazil Mar-1.

Specifications

| Maximum Power | — |

| Maximum Torque | — |

| Emissions | UN ECE R96 Stage IIIA, Brazil MAR-1 |

Benefits & Features

A lifetime of low cost

Fuel consumption is optimised to match the operating cycles of a wide range of agricultural tractors.

Hydraulic tappets, multi-vee belts and 500 hour service intervals enable low cost maintenance

Dependable power

The engine has been designed using the latest predictive engineering methods, combined with an extensive

field validation program to ensure reliable power in the toughest off-highway conditions.

Quality, reliability and consistency are assured. Our facilities worldwide employ the same efficient processes,

the same tested and validated components, and the same stringent quality controls wherever your engines are manufactured.

Industry leading flexibility

A modular engine concept allows OEMs to design one tractor for different regions. This reduces cost and development time for cooling pack, mounting, hydraulic and control interfaces.

Specifications

| Maximum Power | — |

| Maximum Torque | — |

| Rated Speed | 2000-2400rpm |

| Minimum Power | — |

| Emissions | UN ECE R96 Stage IIIA, Brazil MAR-1 |

| Number of Cylinders | 4 inline |

| Cycle | 4 Stroke |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Compression Ratio | 17.0:1 |

| Aspiration | Turbocharged aftercooled |

| Combustion System | Direct injection |

| Rotation from Flywheel End | Anti-clockwise |

| Aftertreatment | - |

| Cooling System | Liquid |

| Length | — |

| Width | — |

| Height | — |

| Dry Weight | — |

| Note 1 | *Final dimensions dependent on selected options |

Benefits & Features

A lifetime of low cost

Fuel consumption is optimised to match the operating cycles of a wide range of agricultural tractors.

Hydraulic tappets, multi-vee belts and 500 hour service intervals enable low cost maintenance

Dependable power

The engine has been designed using the latest predictive engineering methods, combined with an extensive

field validation program to ensure reliable power in the toughest off-highway conditions.

Quality, reliability and consistency are assured. Our facilities worldwide employ the same efficient processes,

the same tested and validated components, and the same stringent quality controls wherever your engines are manufactured.

Industry leading flexibility

A modular engine concept allows OEMs to design one tractor for different regions. This reduces cost and development time for cooling pack, mounting, hydraulic and control interfaces.

Warranties and Perkins Platinum Protection

We provide one-year warranties for constant speed engines and two-year warranties for variable speed models, as standard. These are supported by Perkins Platinum Protection that can be bought additionally.

Discover more: www.perkins.com ‘Parts and Service’.

Local support, global coverage

Perkins recognise that the customer relationship is important to machine manufacturers and we can offer arange of flexible solutions to help provide appropriate support, either to the OEM’s network or directly to the machine customer.

Perkins information systems enable our distributors to quickly diagnose engine faults and identify the right parts.

The Perkins logistics operation is able to dispatch more than 45,000 different parts from stock, reaching the customer within 24 hours.

To find your local distributor: www.perkins.com ‘Our Network’.

Data not available.

Standard Equipment

- Electrical and Electronics

- 12V systems

- Data interface via CANbus J1939

- Full electronic control

- Glow plugs for best cold starting with minimum battery impact

- High power alternator and starter motor options

- Sensors and robust wiring harness included

- Wide choice of interfaces for common transmissions

- Fuel System

- Electronic high pressure common rail

- Fuel filter - chassis mounted

- Water sensor included - early warning for operator

- General

- Structual sump including twin balancers for front bolster mounting

- Cold-start capable with standard equipment to -25°C

- Supplied painted or lacquered

- Ag backplate for transmission mounting

- Oil System

- Oil filters. Mounting options available on either side of the engine, plus remote

- Dipsticks. Choice of position and length

- Oil fillers. Multiple locations on engine to allow for choice of service access

- High incline sump. 25° continuous in all directions

- Power Take-Off (PTO)

- SAE-A and SAE-B interfaces available