Overview

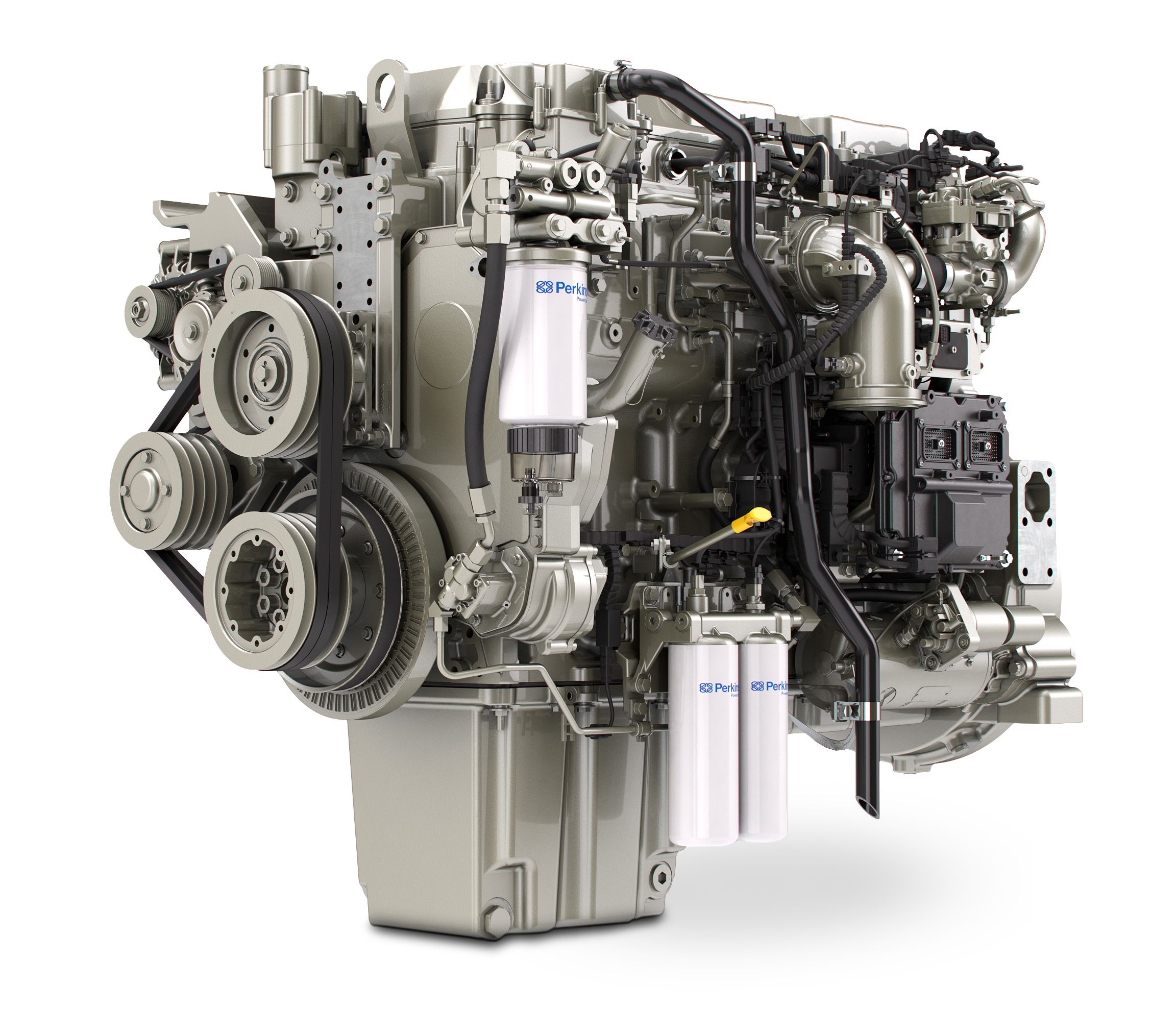

The ability to power your machine line-up with one engine supplier is truly achieveable with Perkins. We have introduced a platform of 9-18 litre industrial engines that completes our market-leading industrial power range and covers 8.8-597 kW (11.8-800 hp).

EU Stage V - ready.Specifications

| Maximum Power | — |

| Maximum Torque | — |

| Emissions | EU Stage V |

Benefits & Features

A lifetime of low cost

We have designed the Perkins 2000 range with optimised fluid (DEF and Fuel) consumption in mind, matching it to the operating cycles of a wide range of equipment and applications. Low cost maintenance is achieved through a minimum 5,000 hour aftertreatment service interval and 500 hour oil change intervals. Transparent regeneration of the aftertreatment provides minimum downtime.

Dependable Power

The Perkins 2000 range is suitable for the toughest operating conditions. Built in a world class manufacturing facility, and with proven core engine designs you can be assured of many hours of productive life. Aftertreatment designed to perform through the whole work cycle of the engine, supporting productivity of machines in all conditions.

Low cost of Installation

Features built into the 2000 Range provide opportunities to reduce the cost of installation into your machine. With a compact package size of the engine, supported by multiple options available to support optimisation for your application. Supported by our expertise of application installations, the knowledge required to improve total integration is at all times you work with Perkins. Flexibility in aftertreatment installation, including horiztonal and vertical options.

Specifications

| Maximum Power | — |

| Maximum Torque | — |

| Rated Speed | 1800-2100 rpm |

| Minimum Power | — |

| Emissions | EU Stage V |

| Number of Cylinders | 6 inline |

| Cycle | 4 stroke |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Compression Ratio | 17.0:1 |

| Aspiration | Turbocharged aftercooled |

| Combustion System | Direct injection |

| Rotation from Flywheel End | Anti-clockwise |

| Aftertreatment | DOC+DPF+SCR |

| Cooling System | Liquid |

| Length | — |

| Width | — |

| Height | — |

| Dry Weight | — |

| Note 1 | *Final dimensions dependent on selected options |

Benefits & Features

A lifetime of low cost

We have designed the Perkins 2000 range with optimised fluid (DEF and Fuel) consumption in mind, matching it to the operating cycles of a wide range of equipment and applications. Low cost maintenance is achieved through a minimum 5,000 hour aftertreatment service interval and 500 hour oil change intervals. Transparent regeneration of the aftertreatment provides minimum downtime.

Dependable Power

The Perkins 2000 range is suitable for the toughest operating conditions. Built in a world class manufacturing facility, and with proven core engine designs you can be assured of many hours of productive life. Aftertreatment designed to perform through the whole work cycle of the engine, supporting productivity of machines in all conditions.

Low cost of Installation

Features built into the 2000 Range provide opportunities to reduce the cost of installation into your machine. With a compact package size of the engine, supported by multiple options available to support optimisation for your application. Supported by our expertise of application installations, the knowledge required to improve total integration is at all times you work with Perkins. Flexibility in aftertreatment installation, including horiztonal and vertical options.

Data not available.

Standard Equipment

- Aftertreatment Equipment

- ECU - Aftertreatment Electronic Control Units

- PETU - Pump Electronic Tank Unit

- SCR Auxiliaries - A range of tanks and heated lines are available

- Air System

- Turbocharged aftercooled

- Electrical and Electronics

- All connectors and wiring looms waterproof and designed to withstand harsh off-highway environments

- Flexible and configurable software features and well supported SAE J1939 CAN bus enables highly integrated machines

- Full electronic control system

- Cooling System

- Detailed guidance on cooling system design and validation available to ensure machine reliability

- Vertical outlet thermostat housing, centifugal water pump

- Flywheel and Flywheel Housing

- Wide choice of drivetrain interfaces, SAE1 configurations

- Fuel System

- Mechanical Unit Injector fuel system, controlled electronically

- Industrial technology requires Ultra Low Sulphur Diesel fuel (ULSD, 15 ppm sulphur), in addition to ultra low sulphur diesel oils, for use in Tier 4 Final/Stage IV engines. These cleaner fuels and oils will help reduce ash and maintain service intervals. In addition, B20 biodiesel capability adds even greater sustainability where desired or required

- Oil System

- Choice of sumps for different applications

- Oil cooler, oil filler, oil filter, oil dipstick, oil pump (gear-driven)

- Open crankcase ventilation system with fumes disposal (optional OCV filter system)

- Power Take-Off (PTO)

- Engine power can also be taken from the front of the engine on some applications

- SAE1 power take-off available with optional SAE A, SAE B and SAE C power take-off drives