Overview

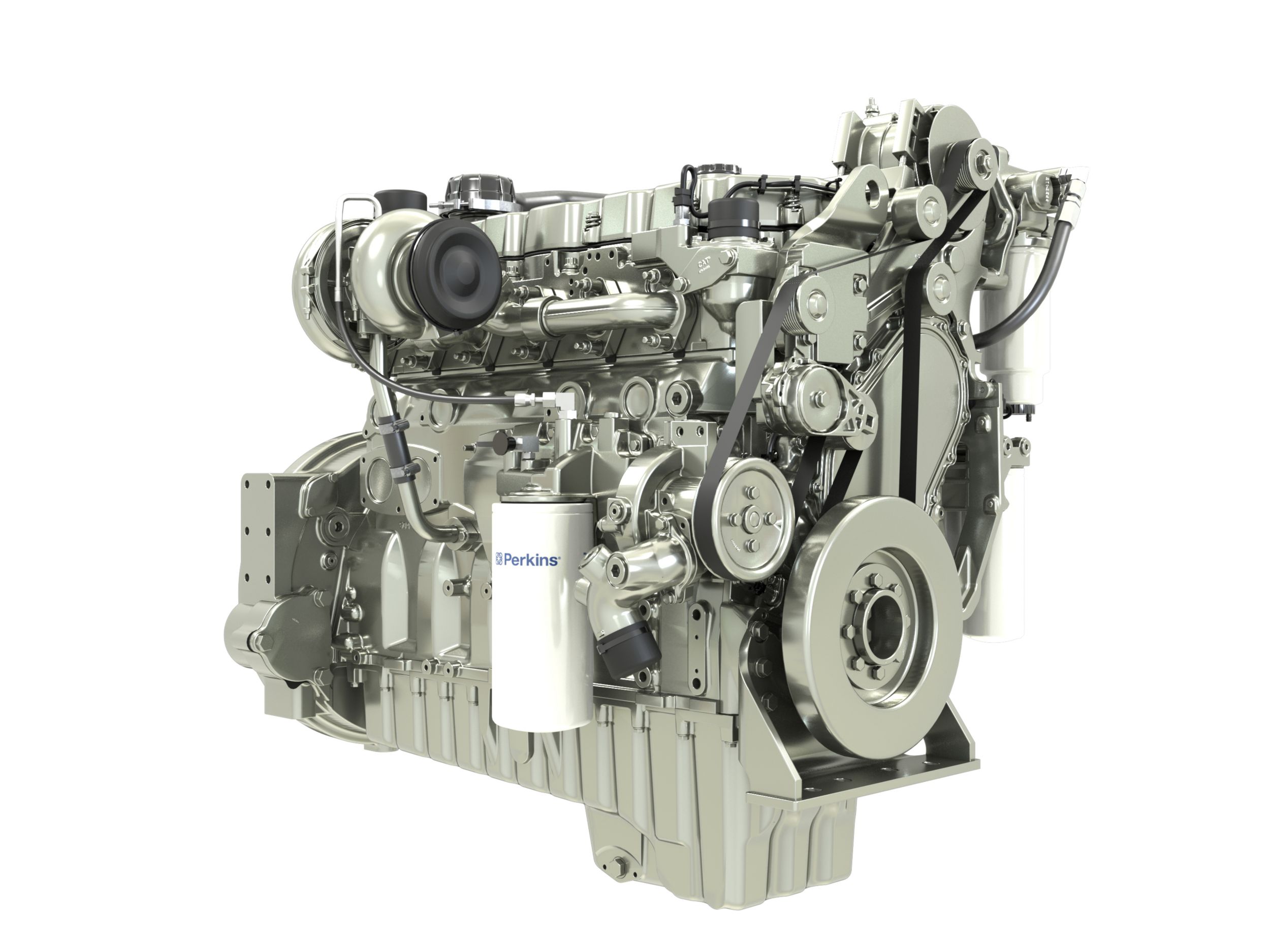

The Perkins® 1706D-E93TA is a 6 cylinder, 9.3 litre engine that produces up to 310 kW (416 hp) of power and 1810 Nm (1335 lb-ft) of torque out of a compact, lightweight package. The 1706D model is a platform extension of the 1706J and meets China Nonroad Stage III, Brazil MAR-1, and UN R96 Stage IIIA emission standards and UN R120 performance standard for measurement of net power and specific fuel consumption.

Specifications

| Maximum Power | — |

| Maximum Torque | — |

| Emissions | China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIA |

Benefits & Features

A lifetime of low cost

High power and torque density, providing the opportunity to downsize in engine displacement without sacrificing performance or reliability

Dependable power

World-class manufacturing capability and processes coupled with proven core engine designs assure reliability, quiet operation and many hours of productive life

High performance

High power and torque density, providing the opportunity to downsize in engine displacement without sacrificing performance or reliability

Specifications

| Maximum Power | — |

| Maximum Torque | — |

| Rated Speed | 1800-2200 rpm |

| Minimum Power | — |

| Emissions | China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIA |

| Number of Cylinders | 6 inline |

| Cycle | 4 stroke |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Compression Ratio | 16.5:1 |

| Aspiration | Turbocharged aftercooled |

| Combustion System | Direct injection |

| Rotation from Flywheel End | Anti-clockwise |

| Aftertreatment | - |

| Cooling System | Liquid |

| Length | — |

| Width | — |

| Height | — |

| Dry Weight | — |

| Note 1 | *Final dimensions dependent on selected options |

Benefits & Features

A lifetime of low cost

High power and torque density, providing the opportunity to downsize in engine displacement without sacrificing performance or reliability

Dependable power

World-class manufacturing capability and processes coupled with proven core engine designs assure reliability, quiet operation and many hours of productive life

High performance

High power and torque density, providing the opportunity to downsize in engine displacement without sacrificing performance or reliability

Data not available.

Standard Equipment

- Air System

- Turbocharged aftercooled

- Electrical and Electronics

- All connectors and wiring looms waterproof and designed to withstand harsh off-highway environments

- Flexible and configurable software features and well-supported SAE J1939 CAN bus enables highly integrated machines

- Full electronic control system with all system functions controlled from a single, engine-mounted electronic control module (ECM)

- Cooling System

- Detailed guidance on cooling system design and validation available to ensure machine reliability

- Vertical outlet thermostat housing, centifugal water pump

- Flywheel and Flywheel Housing

- Wide choice of drivetrain interfaces, SAE2 and SAE1 configurations

- Fuel System

- High Pressure Common rail fuel system

- Oil System

- Choice of sumps for different applications

- Oil cooler, oil filler, oil filter, oil dipstick, oil pump (gear-driven)

- Power Take-Off (PTO)

- Engine power can also be taken from the front of the engine on some applications

- Available SAE No. 1 flywheel housings with rear power take-off (PTO) drive options for SAE B, SAE C or combination.

Optional Equipment

- Oil System

- Open crankcase ventilation system with fumes disposal (optional OCV filter system)