Overview

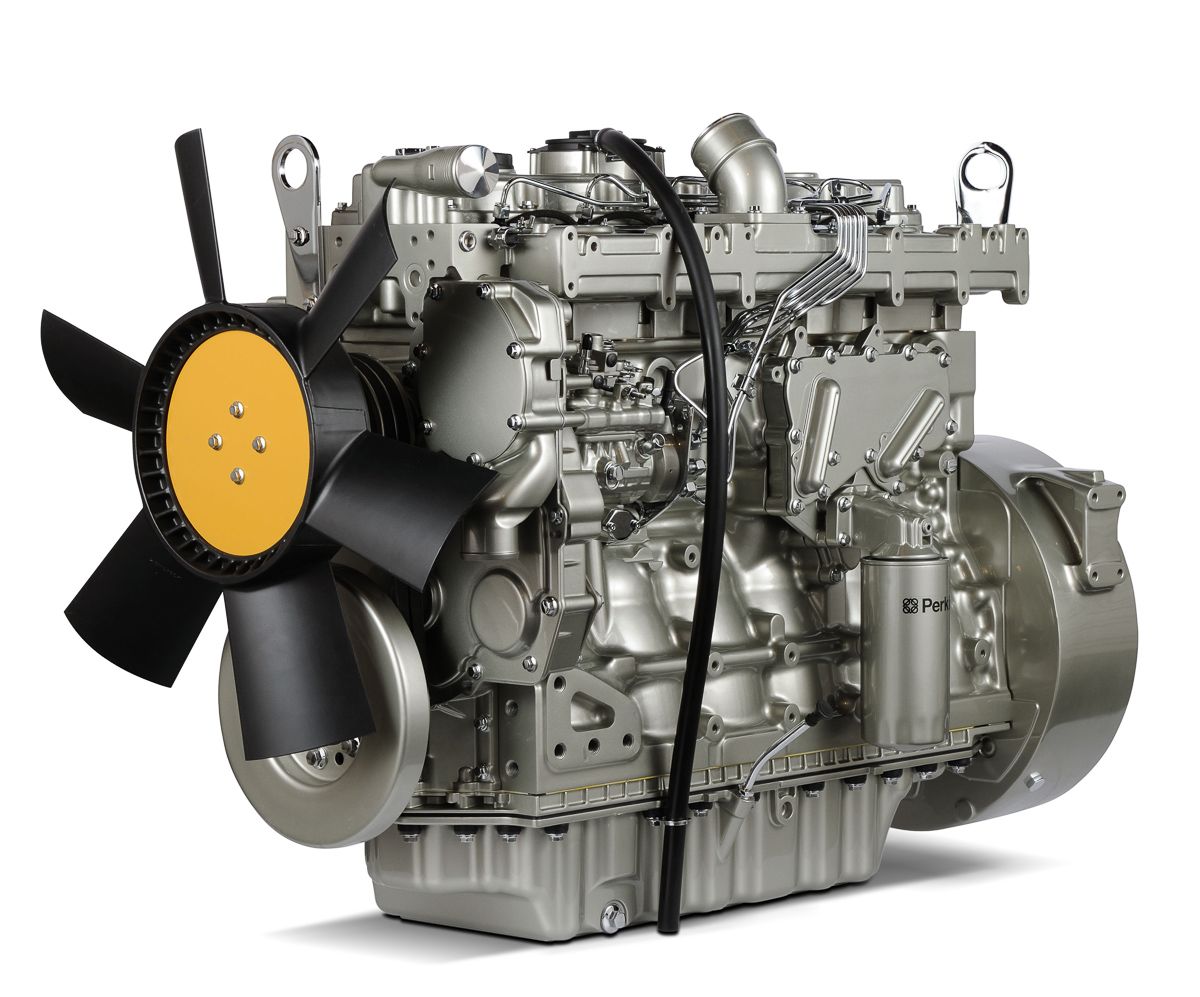

The 1106C provides a common solution to meeting the EU Stage II and U.S. EPA Tier 2 emissions regulations, providing a choice of solutions from the Perkins® 1100 Series diesel engine platform.</p> These clean engines are assembled around optimal, efficient manufacturing processes with state-of-the-art technology. They are built to provide the exact power solution for customers who sell their applications into lesser regulated countries.</p> The new engines boast considerable increases to delivered power, torque and noise reduction. These have been achieved through changes to the manifold and combustion areas, turbocharger geometry, increased cylinder displacement.</p>Focusing on our common platform theme, changes to engine envelope dimensions and connection points have been kept to a minimum.

Specifications

| Maximum Power | — |

| Maximum Torque | — |

| Emissions | EU Stage II/U.S. EPA Tier 2 equivalent |

Benefits & Features

Designed for lesser regulated territories

The 1106 engines have been specifically designed for use in territories with Stage II/IIIA and Tier 2/3 equivalent emissions standards, using the best technologies to ensure a reliable and easy to maintain machine. It uses a turbocharged aftercooled engine to offer the best combination of power delivery and response, whilst still meeting the emissions standards.

Ease of maintenance

The engines have mechanical or electronic fuel injection with standard 500 hour service intervals. And single side service components, for ease of end user servicing.

Easy to upgrade

Common front and rear ends, connection points and components across the range mean that you can easily install a different 1100 Series engine in your application.

Specifications

| Maximum Power | — |

| Maximum Torque | — |

| Rated Speed | 1950-2200 rpm |

| Minimum Power | — |

| Emissions | EU Stage II/U.S. EPA Tier 2 equivalent |

| Number of Cylinders | 6 inline |

| Cycle | 4 stroke |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Compression Ratio | 18.2:1 |

| Aspiration | Turbocharged aftercooled |

| Combustion System | Direct injection |

| Rotation from Flywheel End | Anti-clockwise |

| Aftertreatment | - |

| Cooling System | Liquid |

| Length | — |

| Width | — |

| Height | — |

| Dry Weight | — |

| Note 1 | *Final dimensions dependent on selected options |

Benefits & Features

Designed for lesser regulated territories

The 1106 engines have been specifically designed for use in territories with Stage II/IIIA and Tier 2/3 equivalent emissions standards, using the best technologies to ensure a reliable and easy to maintain machine. It uses a turbocharged aftercooled engine to offer the best combination of power delivery and response, whilst still meeting the emissions standards.

Ease of maintenance

The engines have mechanical or electronic fuel injection with standard 500 hour service intervals. And single side service components, for ease of end user servicing.

Easy to upgrade

Common front and rear ends, connection points and components across the range mean that you can easily install a different 1100 Series engine in your application.

Expertise whenever you need it

With our network of distributors, you will find all the advice you need to ensure you get the right engine. By building strong relationships with you, we make sure you have access to the full power of the Perkins brand and expertise. Our fully trained experts deliver total service support 24/7, 365 days of the year. Whether you need technical information, parts identification or ordering, our distribution network is there to make sure your Perkins engine keeps on running at peak performance.

Oil and fuel filtration

The high quality oil and fuel filtration on our 1100 Series range produces an engine that is reliable and durable. Ecoplus fuel filtration is available to boost its clean running qualities and the engine is capable of running on a wide range of global fuels including biodiesel.

Data not available.

Standard Equipment

- Air System

- Air compressor

- Exhaust manifold

- Induction manifold

- Electrical and Electronics

- Alternator

- Control panel

- Starter motor

- Cooling System

- Cooling pack

- Fan drive

- Flywheel and Flywheel Housing

- Adaptor plate

- Flywheel and starter ring

- SAE B PTO Drive

- Fuel System

- Fuel filter

- General

- Cold start aid

- Engine mountings

- Oil System

- Lubricating oil filter and breather

- Oil filter

- Sound isolated lubricating oil sump

- Power Take-Off (PTO)

- Belt driven auxiliaries

- Front end drive

- Timing case and gear driven auxiliaries