ATC-300+ CONTROLLER

ATC-300+ CONTROLLEROverview

The ATC-300+ is a comprehensive and multifunctional microprocessor-based ATS controller. It is a compact and self-contained panel-mounted device that is designed to replace traditional relay and solid-state logic panels. The ATC-300+ Controller provides programmed flexibility to address the needs of any system. It operates from all system voltages between 120 to 600V, single-phase and three-phase at 50 or 60 Hz. In addition, a period of no control power is provided. The controller monitors the condition of the three-phase line-to-line voltage and frequency of Source 1 and Source 2 power sources and can be programmed for single-phase operation. The ATC-300+ Controller provides the intelligence to ensure that the ATS operates properly through a series of programmed sensing and timing functions.

Specifications

| Rating Range | 120 to 600V, single phase and three phase @ 50/60 Hz |

| Transfer Type | Switch application dependent |

| Switch Type | Switch application dependent |

Benefits & Features

Product Features

- Auxiliary relay contacts:

- Source 1 present 2NO and 2NC

- Source 2 present 2NO and 2NC

- Source 1 and source 2 sensing:

- Undervoltage / underfrequency

- Overvoltage / overfrequency

- Three-phase rotation protection

- Three-phase voltage unbalance/loss

- Pre-transfer signal contacts 1NO and 1NC

- Go to emergency (Source 2)

- Seven field-programmable time delays

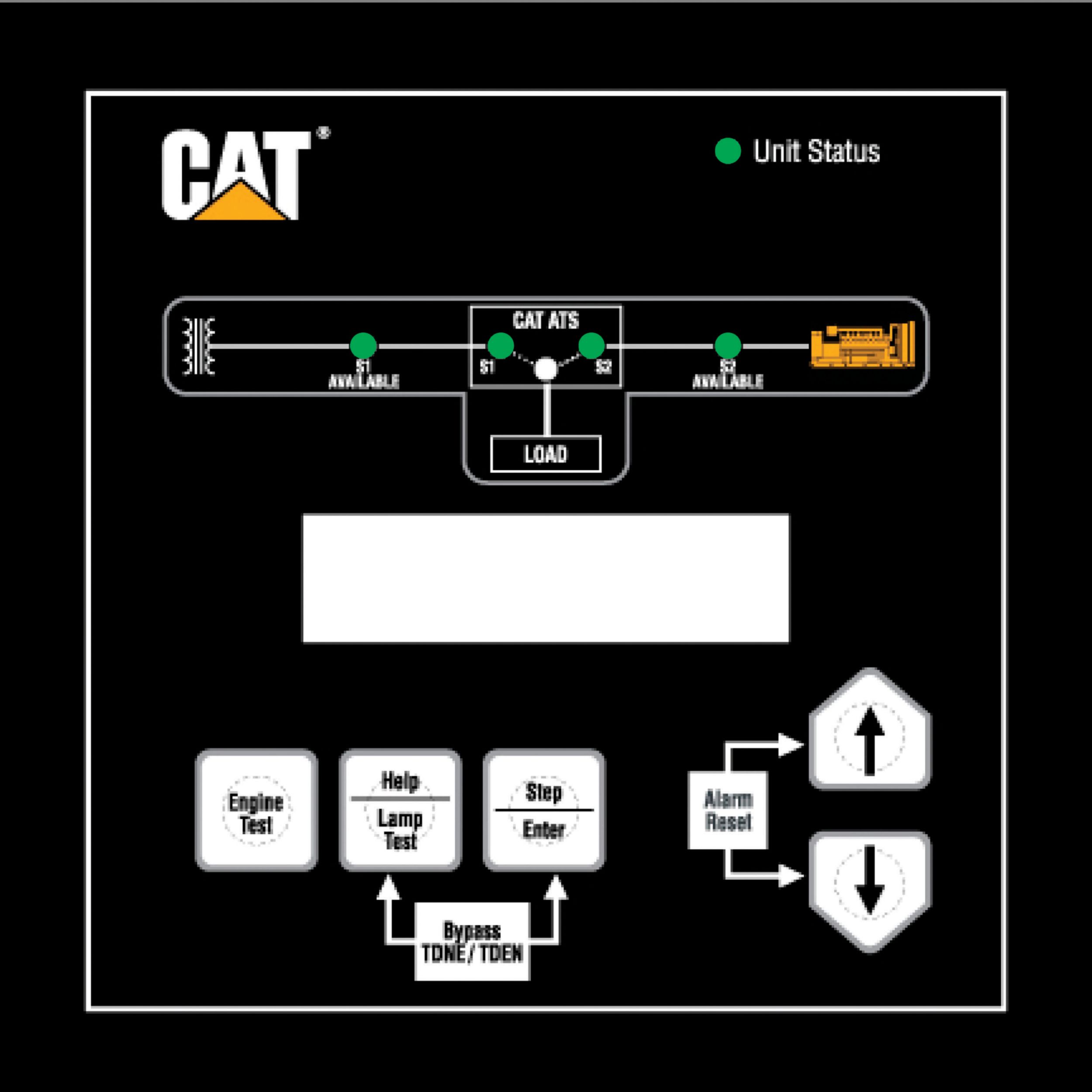

- LCD-based display for programming, system diagnostic and help message display

- Mimic diagram with source available and connected LED indication

- Time-stamped history log

- System test pushbutton

- Programmable plant exercise (off, daily, 7,14 and 28 day) interval selectable run time 0-600 minutes no load/load with fail-safe

- Integral overcurrent protection (optional)

- In-phase transition

- Stainless steel cover for controller (optional)

- Communications via RS-232 or Modbus through an integrated RS-485 port (optional)

Specifications

| Rating Range | 120 to 600V, single phase and three phase @ 50/60 Hz |

| Transfer Type | Switch application dependent |

| Switch Type | Switch application dependent |

| Input Control Voltage | 65 to 145 Vac 50/60 hZ |

| Voltage Measurements of Utility | Source 1 VAB Source 2 VAB<br>Source 1 VAC Source 2 VBC<br>Source 1 VCA Source 2 VCA |

| Voltage Measurement Range | 0 to 790 VAC rms (50/60 Hz) |

| Voltage Measurement Accuracy | +/-2% of nominal input voltage |

| Frequency Measurements Of | Source 1 and Source 2 |

| Frequency Measurement Range | 40 Hz to 70 Hz |

| Frequency Measurement Accuracy | +/- 0.1 Hz |

| Undervoltage Dropout | 50% to 90% of nominal voltage |

| Undervoltage Pickup | (Dropout +2%) to 99% of the nominal system voltage |

| Underfrequency Dropout Range | 90 to 97% of the nominal system frequency |

| Underfrequency Pickup Range | (Dropout +1 Hz) to 99% of the nominal system frequency |

| Overfrequency Dropout Range | 103 to 110% of the nominal system frequency |

| Overfrequency Pickup Range | 101% to (dropout - 1 Hz) of the nominal system frequency |

| Operating Temperature Range | -20 to 70 degree C (-4 to +158 degree F) |

| Storage Temperature Range | -30 to 85 degree C (-22 to +185 degree F) |

| Operating Humidity | 0 to 95% relative humidity (noncondensing) |

| Operating Environment | Resistant to ammonia, methane, nitrogen,hydrogen and hydrocarbons |

| Generator Start Relay | 5A, 1/6 hp @ 250 Vac Vac 5A @ 30 Vdc with a 150W maximum load |

| K1, K2 Relays | <br>10A, 1-3 hp @ 250 Vac</br><br>10A@30 Vdc</br> |

| Applicable Testing | UL-recognized component<br>Meets intent of UL 991 & UL 1008<br>Meets IEC 1000-4-2, 1000-4-3, 1000-4-4 |

| Applicable Testing Continued | 1000-4-5, 1000-4-6, 1000-4-11<br>CISPR 11, Class A<br>FCC Part 15, Class A<br>CSS 22.2-178 |

| Enclosure Compatibility | NEMA 1, NEMA 3R and NEMA 12<br>UV-resistant ATC-300+ faceplate |

Benefits & Features

Product Features

- Auxiliary relay contacts:

- Source 1 present 2NO and 2NC

- Source 2 present 2NO and 2NC

- Source 1 and source 2 sensing:

- Undervoltage / underfrequency

- Overvoltage / overfrequency

- Three-phase rotation protection

- Three-phase voltage unbalance/loss

- Pre-transfer signal contacts 1NO and 1NC

- Go to emergency (Source 2)

- Seven field-programmable time delays

- LCD-based display for programming, system diagnostic and help message display

- Mimic diagram with source available and connected LED indication

- Time-stamped history log

- System test pushbutton

- Programmable plant exercise (off, daily, 7,14 and 28 day) interval selectable run time 0-600 minutes no load/load with fail-safe

- Integral overcurrent protection (optional)

- In-phase transition

- Stainless steel cover for controller (optional)

- Communications via RS-232 or Modbus through an integrated RS-485 port (optional)

Data not available.