MX250 Microprocessor ControllerNon-Current

MX250 Microprocessor ControllerOverview

The MX250 microprocessor is standard with the entire CTS product family. The MX250 Series includes all the standard features of the MX150 Controller while offering expanded programmability and field adaptability. The high reliability and ease of unattended operation makes it ideal to use in a wide range of mission critical applications.

Specifications

Units:

| Rating Range | Switch Dependent |

| Transfer Type | Application Dependent |

| Switch Type | Application Dependent |

Benefits & Features

Features and Benefits

- Available to support ALL transfer modes:

–Open, Delayed and Closed Transition - User-friendly programmable engine exerciser,with or without load, at ANY interval in a one-year period

- A wide variety of operating voltages available in a single controller for most domestic and international applications

- Real-time display of ATS status, including active timer(s)

- Multiple levels of user-defined password protection

- Serial communications allowing connectivity with other ATS's, Caterpillar® Switchgear, and SCADA systems

- Time-tested synchronous logic automatically measures phase angle and frequency allowing disturbance-free transfer

- Unsurpassed statistical ATS/System monitoring available in real-time

- Elevator pre-signal contacts automatically bypassed if the selected source fails, minimizing time an elevator is without power

- Universal Motor Disconnect (UMD) sends a pre-signal, post-signal or both to any motor control center. Not bypassed in an outage,the UMD ensures safety in the event of a single phase loss

- Voltage unbalance detection standard

- Also includes all standard MX150 features

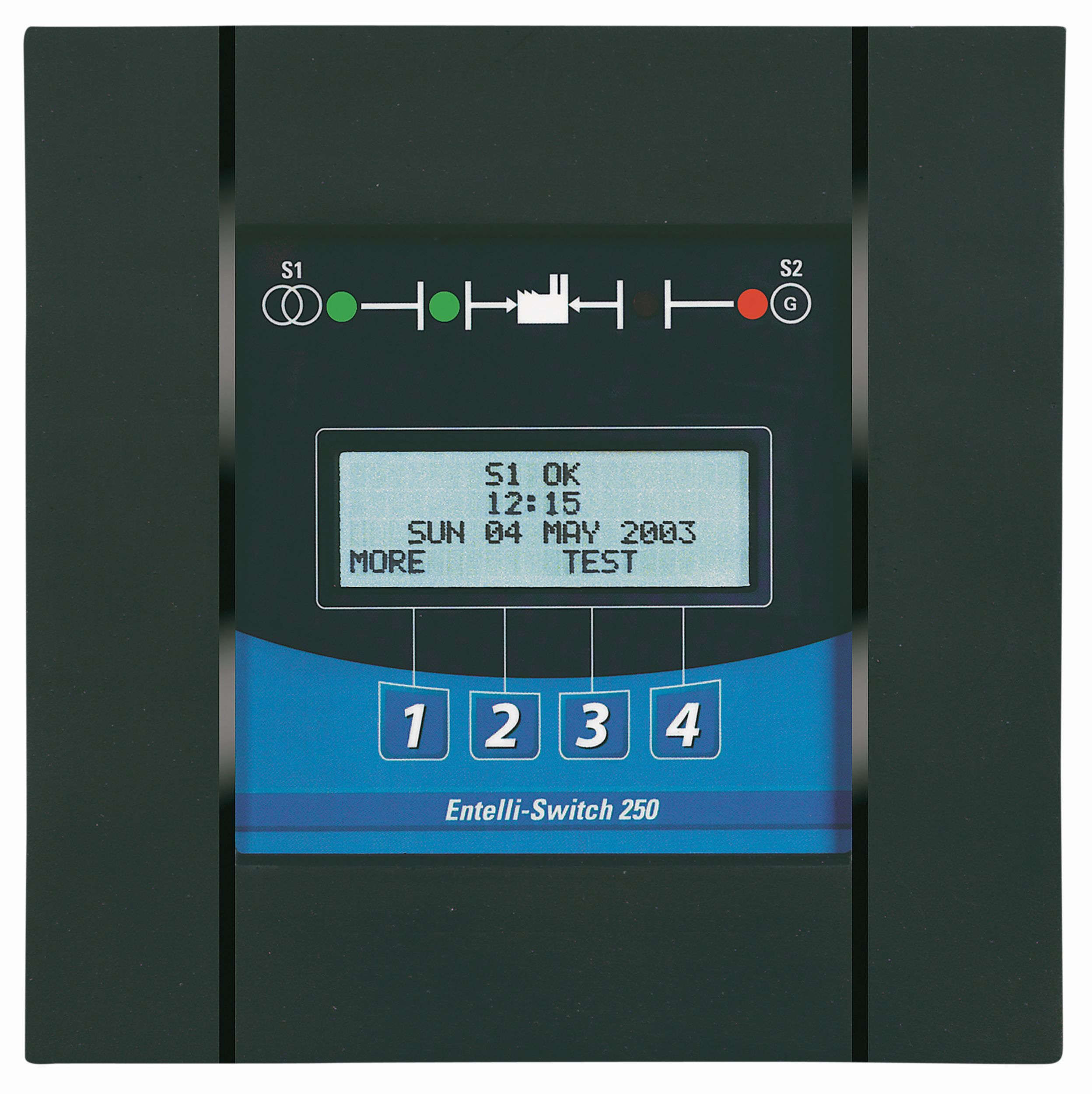

- Back-lit/temperature compensated LCD display (includes the display of source voltage and frequency, exercise time, delay options and source condition)

- Close differential 3-phase under-voltage sensing of source 1, factory standard setting 90% pickup, 80% dropout; under-frequency sensing of source 1 factory setting 95% pickup;voltage and frequency sensing of source 2,factory standard setting 90% pickup voltage,95% pickup frequency.

All factory settings are operator adjustable. - LED indicators for ATS position and source availability

- Plant exerciser clock (configured for 1, 7, 14 or 28 day run selections)

- Built-in time delays with count-down display

- Push button to bypass time delay transfer/retransfer

- Transfer/commit/no commit selection In-phase monitor

- Event logging (last 16 events)

- A test is standard (fast test/load/no load) to simulate source 1 failure – automatically bypassed should source 2 fail.

June 16, 2025

Specifications

Units:

| Rating Range | Switch Dependent |

| Transfer Type | Application Dependent |

| Switch Type | Application Dependent |

| Undervoltage Dropout for Source 1 and Source 2 | 75-98% of nominal |

| Undervoltage Restore for Source 1 and Source 2 | 85-100% of nominal |

| Underfrequency Dropout for Source 1 and Source 2 | 90-100% of nominal |

| Delay for Engine Cool Down (U) | 0-60 minutes |

| Delay Transfer to Nonpreferred Source (W) | 0-5 minutes |

| Delay NeutralTransition Time Delays (DT,DW) | 0-10 minutes |

| Storage Temperature | (-30˚C - 75˚C ), -22˚F - 167˚F |

| Operating Temperature Ambient | 40 - 400 amp molded shell (-20˚C to 65˚C) , -4˚F to 149˚F <br>40 - 4000 amp all others (-20˚C to 60˚C), -4˚F to 149˚F |

Benefits & Features

Features and Benefits

- Available to support ALL transfer modes:

–Open, Delayed and Closed Transition - User-friendly programmable engine exerciser,with or without load, at ANY interval in a one-year period

- A wide variety of operating voltages available in a single controller for most domestic and international applications

- Real-time display of ATS status, including active timer(s)

- Multiple levels of user-defined password protection

- Serial communications allowing connectivity with other ATS's, Caterpillar® Switchgear, and SCADA systems

- Time-tested synchronous logic automatically measures phase angle and frequency allowing disturbance-free transfer

- Unsurpassed statistical ATS/System monitoring available in real-time

- Elevator pre-signal contacts automatically bypassed if the selected source fails, minimizing time an elevator is without power

- Universal Motor Disconnect (UMD) sends a pre-signal, post-signal or both to any motor control center. Not bypassed in an outage,the UMD ensures safety in the event of a single phase loss

- Voltage unbalance detection standard

- Also includes all standard MX150 features

- Back-lit/temperature compensated LCD display (includes the display of source voltage and frequency, exercise time, delay options and source condition)

- Close differential 3-phase under-voltage sensing of source 1, factory standard setting 90% pickup, 80% dropout; under-frequency sensing of source 1 factory setting 95% pickup;voltage and frequency sensing of source 2,factory standard setting 90% pickup voltage,95% pickup frequency.

All factory settings are operator adjustable. - LED indicators for ATS position and source availability

- Plant exerciser clock (configured for 1, 7, 14 or 28 day run selections)

- Built-in time delays with count-down display

- Push button to bypass time delay transfer/retransfer

- Transfer/commit/no commit selection In-phase monitor

- Event logging (last 16 events)

- A test is standard (fast test/load/no load) to simulate source 1 failure – automatically bypassed should source 2 fail.

Data not available.

Standard Equipment

- Performance

- ESD immunity test per EN61000-4-2 Class B(Level 4)

- Electrical fast transient/burst immunity test perEN61000-4-4

- Conducted and Radiated Emissions per EN55022Class B (CISPR11) (Exceeds EN55011 & MILSTD461 Class 3)

- Voltage dips and interruption immunity EN61000-4-11

- Conducted immunity test per EN61000-4-6(ENV50141)

- Ringing wave immunity per IEEE 472(ANSIC37.90A)

- Surge immunity test per EN61000-4-5 IEEE C62.41

- UL, CSA and IEC listed

- Radiated RF, electromagnetic field immunitytest per EN61000-4-3 (ENV50140) 10v/m

- User Friendly Operation

- Weather and tamper resistant touchpad

- Through-the-door programming and display

- Multipurpose display: LEDs for continuous monitoring of switch position and source availability; a four line by twenty character LCD display for settings, functions, programming and annunciation

- Simplified keypad entry – menu-driven system is designed for ease of use

- Built-in diagnosis with displays for ease of troubleshooting

- Additional Features

- User settings are unaffected by power outages

- Built-in programmable exerciser uses separate microcontroller with independent battery back-up to serve as clock/calendar – battery failure will not affect switch operation

- Built-in electrical operator protection

- Inputs are optoisolated for high electrical immunity to transients and noise

- Source connection and transfer data logging

- Separate line voltage components for controller isolation

- Watchdog circuit for microprocessor operation