Overview

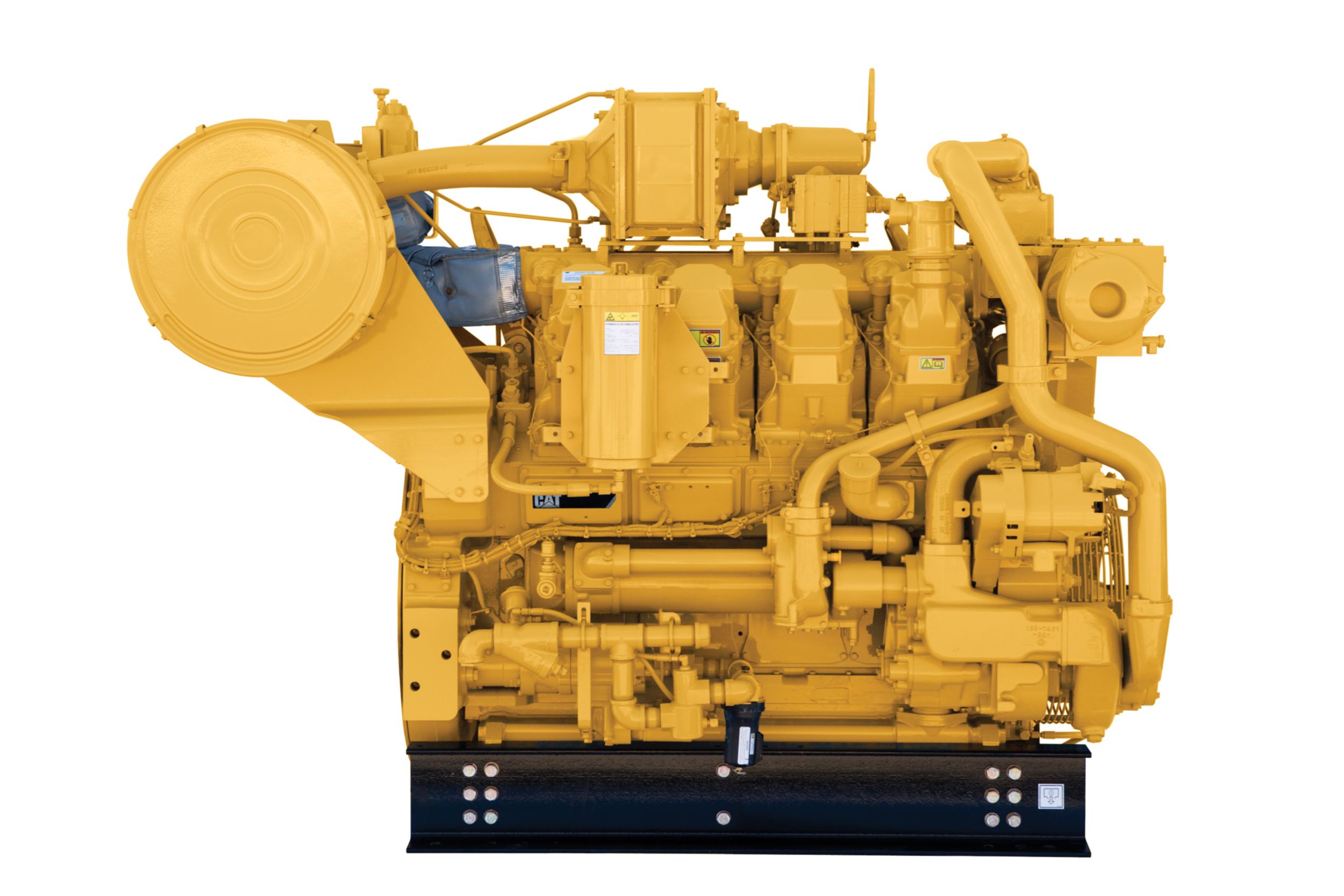

The line of G3500B engines brings versatility, uptime, and low operating cost to your gas compression operation. They deliver the lowest engine-out emissions in the industry without sacrificing performance.Ideal applications for G3500B engines include gas lift, gas gathering, and wellhead gas compression. Cat G3508B gas engine. Ratings: 514 bkW (690 bhp) @ 1400 rpm are NSPS site compliant capable.

Specifications

| Maximum Rating | — |

| Emissions | NSPS Site Compliant Capable |

| Displacement | — |

Benefits & Features

Engine Design

- Built on G3500 LE proven reliability and durability- Ability to burn a wide spectrum of gaseous fuels- Robust diesel strength design prolongs life and lowersowning and operating costs- Broad operating speed range at lower site air densities(high altitude/hot ambient temperatures)- Higher power density improves fleet management- Quality engine diagnostics- Detonation-sensitive timing control for individualcylinders

Ultra Lean Burn Technology (ULB)

ULB technology uses an advanced control system, abetter turbo match, improved air and fuel mixing, and amore sophisticated combustion recipe to provide:- Lowest engine-out emissions- Highest fuel efficiency- Improved altitude and speed turndown- Stable load acceptance and load rejection

Emissions

- Meets U.S. EPA Spark Ignited Stationary NSPSemissions for 2010 and some non-attainment areas- Lean air/fuel mixture provides best available emissionsand fuel efficiency for engines of this bore size

Specifications

| Maximum Rating | — |

| Emissions | NSPS Site Compliant Capable |

| Displacement | — |

| Minimum Rating | — |

| Ignition, Protection | ADEM™ A3 |

Benefits & Features

Engine Design

- Built on G3500 LE proven reliability and durability- Ability to burn a wide spectrum of gaseous fuels- Robust diesel strength design prolongs life and lowersowning and operating costs- Broad operating speed range at lower site air densities(high altitude/hot ambient temperatures)- Higher power density improves fleet management- Quality engine diagnostics- Detonation-sensitive timing control for individualcylinders

Ultra Lean Burn Technology (ULB)

ULB technology uses an advanced control system, abetter turbo match, improved air and fuel mixing, and amore sophisticated combustion recipe to provide:- Lowest engine-out emissions- Highest fuel efficiency- Improved altitude and speed turndown- Stable load acceptance and load rejection

Emissions

- Meets U.S. EPA Spark Ignited Stationary NSPSemissions for 2010 and some non-attainment areas- Lean air/fuel mixture provides best available emissionsand fuel efficiency for engines of this bore size

Advanced Digital Engine Management

ADEM A3 engine management system integrates speedcontrol, air/fuel ratio control, and ignition/detonationcontrols into a complete engine management system.ADEM A3 has improved: user interface, display system,shutdown controls, and system diagnostics.

Full Range of Attachments

Large variety of factory-installed engine attachmentsreduces packaging time.

Testing

Every engine is full-load tested to ensure proper engineperformance.

Gas Engine Rating Pro

GERP is a web-based program designed to provide siteperformance capabilities for Cat®natural gas enginesfor the gas compression industry. GERP providesengine data for your site's altitude, ambient temperature,fuel, engine coolant heat rejection, performance data,installation drawings, spec sheets, and pump curves.

Product Support Offered Through Global Cat Dealer

More than 2,200 dealer outletsCat factory-trained dealer technicians service everyaspect of your petroleum engineCat parts and labor warrantyPreventive maintenance agreements available for repairbefore-failure optionsS•O•SSM program matches your oil and coolant samplesagainst Caterpillar set standards to determine:- Internal engine component condition- Presence of unwanted fluids- Presence of combustion by-products- Site-specific oil change interval

Over 80 Years of Engine Manufacturing Experience

Over 60 years of natural gas engine productionOwnership of these manufacturing processes enablesCaterpillar to produce high quality, dependable products- Cast engine blocks, heads, cylinder liners, and flywheelhousings- Machine critical components- Assemble complete engine

Web Site

For all your petroleum power requirements, visit www.catoilandgasinfo.com

Data not available.

Standard Equipment

- Air Inlet System

- Axial Flow Air cleaner

- Cleanable

- Single element canister type with service indicator

- Control System

- ADEM A3 with integrated electronic throttle control

- CSA certified

- Cooling System

- Two-stage charge air cooling

- Thermostats and housing

- Gear-driven jacket and aftercooler water pump

- Stainless steel aftercooler cores

- Exhaust System

- Dry exhaust manifolds

- Exhaust outlet: 200 mm I.D.

- Flywheels and Flywheel Housings

- SAE No. 00 flywheel

- SAE No. 00 flywheel housing

- SAE standard rotation

- Fuel System

- 7-50 psi gas supply

- Electronic fuel metering valve

- Gas pressure regulator, pivot valve operated

- Ignition System

- ADEM A3

- Outdoor CSA certified

- Lubrication System

- Crankcase breather — top mounted

- Oil cooler

- Oil filter — RH

- Oil pan

- Oil sampling valve

- Turbo oil accumulator

- Power Take-Offs

- Front housing — two-sided

- Front lower — LH accessory drive

- Torsional Vibration Analysis

- Provided through Caterpillar, required through Q1 2010

- General

- Paint — Cat yellow

- Crankshaft vibration damper and guard

Optional Equipment

- Air Inlet System

- Round air inlet adaptors

- Charging System

- Battery chargers

- CSA certified version available with

- Cooling System

- Mechanical joint assembly connections

- Exhaust System

- Flexible fittings

- Elbows

- Flanges

- Fuel System

- Gas filter

- Instrumentation

- Advisor display panel

- Communications module

- Lubrication System

- Lubricating oil

- Oil bypass filter

- Air prelube pump

- Power Take-Offs

- Front stub shaft

- Pulleys

- General

- Special paint

- EU Certification

- EEC DOI certification

- Support

- Factory commissioning