Overview

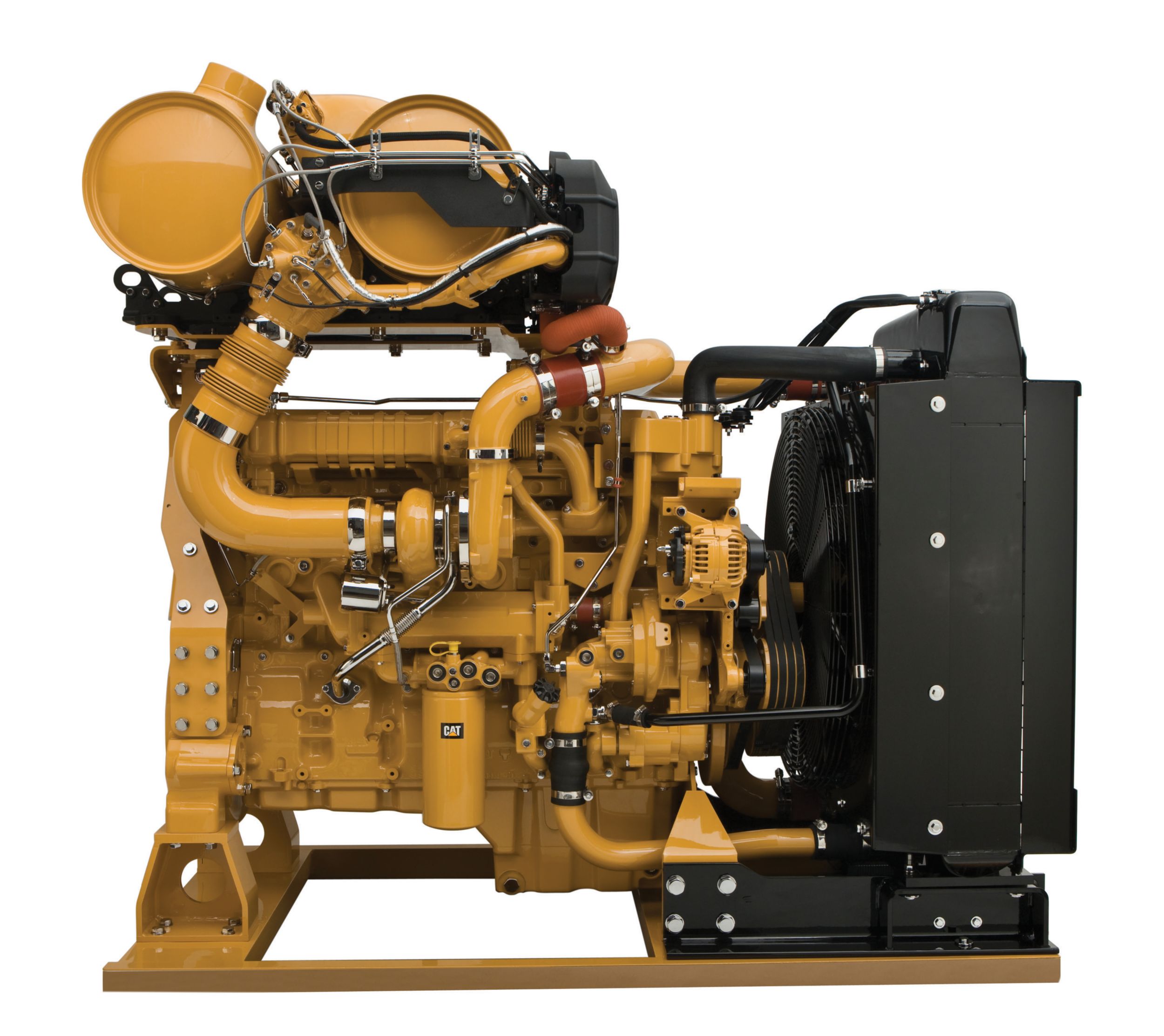

Cat C13 ACERT engines are the ideal solution for your demanding operations in the oilfield. Decades of field operation and intense research and development allow Cat C13 ACERT engines to deliver excellent performance with low operating costs while meeting tight environmental requirements.This is an ideal engine for applications that require compliance with the highest emission standards in well service applications such as workover rigs, pump skids, acidizing units, cementing units, and hydraulic power units.Cat engines are backed by the worldwide network of Cat dealers ready to support your operation with technical support, service, parts, and warranty.C13 ACERT engines with ratings: 287-388 bkW (385-520 bhp) @ 1800-2100 rpm are designed to meet U.S. EPA Tier 4 Final, EU Stage IV emission standards. This information about Emissions describes the particular rating's emissions technology. For more information about emissions certification, please contact your local Cat dealer.

Specifications

| Maximum Rating | — |

| Emissions | EPA Tier 4 Final and EU Stage IV |

| Displacement | — |

Benefits & Features

Emissions

Designed to meet U.S. EPA Tier 4 Final and EU Stage IV emission standards.

Reliable, Quiet, and Durable Power

World-class manufacturing capability and processes coupled with proven core engine designs assure reliability, quiet operation, and many hours of productive life.

High Performance

Simple and efficient turbocharger with balance valve provides optimal air management and improved fuel efficiency.

Specifications

| Maximum Rating | — |

| Displacement | — |

| Minimum Rating | — |

| Aspiration | Turbocharged-Aftercooled |

| Flywheel and Flywheel Housing | SAE 1 |

| Flywheel Teeth | 113 |

| Stroke | — |

| Bore | — |

| Emissions | EPA Tier 4 Final and EU Stage IV |

| Length | — |

| Width | — |

| Height | — |

| Weight | — |

Benefits & Features

Emissions

Designed to meet U.S. EPA Tier 4 Final and EU Stage IV emission standards.

Reliable, Quiet, and Durable Power

World-class manufacturing capability and processes coupled with proven core engine designs assure reliability, quiet operation, and many hours of productive life.

High Performance

Simple and efficient turbocharger with balance valve provides optimal air management and improved fuel efficiency.

Fuel Efficiency

Fuel consumption optimized to match operating cycles of a wide range of equipment and applications.

Fuel & Oil

Tier 4 Final, Stage IV engines require Ultra Low Sulfur Diesel (ULSD) fuel containing a maximum of 15 ppm sulfur, and new oil formulations to support the new technology. Cat® engines are designed to accommodate B20 biofuel. Your Cat dealer can provide more information regarding fuel and oil.

Broad Application Range

Industry-leading range of factory configurable ratings and options for agricultural, materials-handling, construction, mining, forestry, waste, and other industrial applications.

Package Size

Exceptional power density enables standardization across numerous applications. Multiple installation options available to minimize total package size.

Low-Cost Maintenance

Worldwide service delivers ease of maintenance and simplifies the servicing routine. Minimum 5000-hour diesel particulate filter (DPF) ash service interval enables low-cost maintenance. Capable of optimal oil change intervals of up to 500 hours, depending on rating, application, operating conditions, and maintenance practices. Engine is designed for a B10 life of up to 10,000 hours. The S•O•SSMprogram is available from your Cat dealer to determine oil change intervals and provide optimal performance.

Quality

Every Cat engine is manufactured to stringent standards in order to assure customer satisfaction.

World-class Product Support Offered Through

• Scheduled maintenance, including S•O•SSM sample• Customer Support Agreements (CSA)• Caterpillar Extended Service Coverage (ESC)• Superior dealer service network • Extended dealer service network through the Cat Industrial Service Distributor (ISD) program

Data not available.

Standard Equipment

- Control System

- Electronic control system, over-foam wiring harness, automatic altitude compensation, power compensated for fuel temperature, remote fan control, configurable software features, engine monitoring system SAE J1939 broadcast and control, integrated Electronic Control Unit (ECU)

- Cooling System

- Cooling package provides additional auxiliary heat load capacity capable of a minimum 10% of engine rated power. See the Web Ambient Tool (https://wbdat.cat.com/) for estimated ambient capability based on rating, fan drive ratio, fan, altitude and auxiliary heat load.

- Exhaust System

- Mid-mount turbocharged system with front and rear exhaust configurations

- Flywheels and Flywheel Housing

- SAE No. 1 flywheel housing; available SAE 1 power take-off housing with optional SAE A, SAE B, and SAE C power take-off drives; engine power can also be taken from the front of the engine with optional attachments

- Fuel System

- MEUI injection; primary fuel filter, secondary fuel filters, fuel transfer pump, electronic fuel priming

- Lube System

- Open crankcase ventilation system with fumes disposal (optional OCV filter system); oil cooler, oil filler, oil filter, oil dipstick, oil pump (gear-driven); choice of sumps (front, rear, and center)

- General

- Paint: Cat yellow