Overview

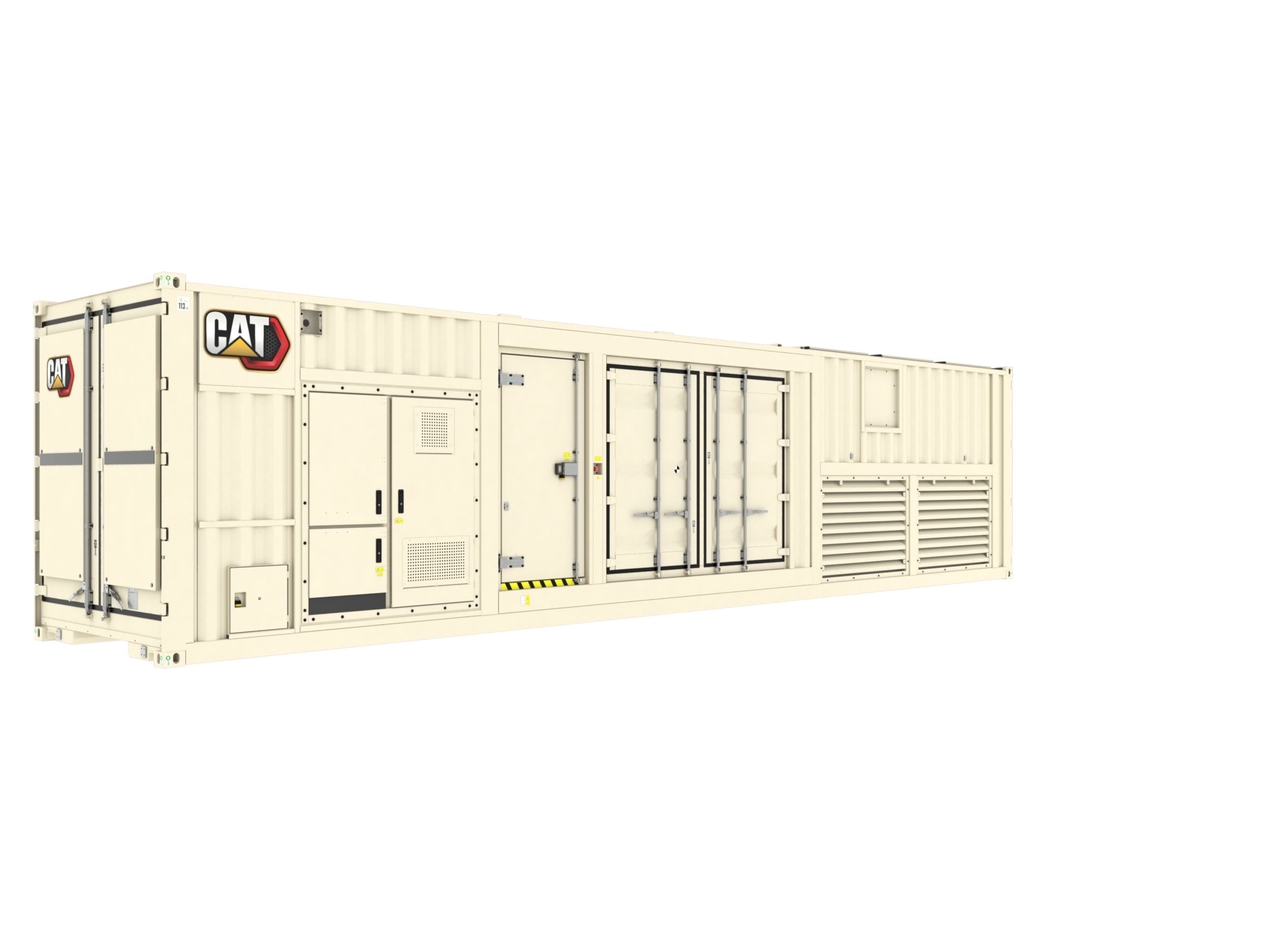

In addition to improved fuel efficiency, the next generation XGC1900 rental generator provides significant power density advantages. Caterpillar developed new exhaust stacks that reduce spacing requirements for sites requiring multiple units.

Specifications

| Rating | 1900 ekW (2375 kVA) Continuous |

| Frequency | 50/60 Hz |

| Voltage | 400/480 V |

Benefits & Features

Rental Ready

Extensive range of rental ready features to meet job requirements and applications.

Fuel/Emissions Strategy

Meets most worldwide emissions requirements down to 500 mg/Nm3 NOx level without after treatment.

Cat® G3516H High Altitude and Ambient Gas Engine

Compact, four-stroke-cycle G3516H gas engine provides exceptional dependability, fuel economy and power density for reduced total cost of ownership High altitude and ambient hardware improvesengine’s capability to handle electrical loading andunloading, as well as ambient and altitude capability. High fuel tolerant hardware improves humiditytolerance and allows usage of lower MN fuel Operates on 24.10 to 93.95 MJ/Nm3(615 to 2386 btu/ft3) dry pipeline natural gas Island mode feature improves engine's capability to handle electrical loading and unloading

Specifications

| Rating | 1900 ekW (2375 kVA) Continuous |

| Frequency | 50/60 Hz |

| Voltage | 400/480 V |

| Engine | Cat G3516H |

| Fuel | Natural Gas |

| Width - Without Chassis | — |

| Height - Without Chassis | — |

| Length - Without Chassis | — |

| Weight - Without Chassis, With Lube Oil and Coolant | — |

Benefits & Features

Rental Ready

Extensive range of rental ready features to meet job requirements and applications.

Fuel/Emissions Strategy

Meets most worldwide emissions requirements down to 500 mg/Nm3 NOx level without after treatment.

Cat® G3516H High Altitude and Ambient Gas Engine

Compact, four-stroke-cycle G3516H gas engine provides exceptional dependability, fuel economy and power density for reduced total cost of ownership High altitude and ambient hardware improvesengine’s capability to handle electrical loading andunloading, as well as ambient and altitude capability. High fuel tolerant hardware improves humiditytolerance and allows usage of lower MN fuel Operates on 24.10 to 93.95 MJ/Nm3(615 to 2386 btu/ft3) dry pipeline natural gas Island mode feature improves engine's capability to handle electrical loading and unloading

CAT EMCP Control Panel

EMCP 4.3 control panel offers engine and generator monitoring and protection Fully featured power metering, protective relaying, and engine/generator control and monitoring On-Package Auto Paralleling Controls AGC-4 provides paralleling, load sharing, VFD control, and additional generator protection

Cat Generator

Cat SR5 generator designed to match the performance and output characteristics of the Cat Gas engine. Class H insulation operating at Class F temperature rise for extended life. System 4 insulation protection and anti-condensation space heaters. Integrated Automatic Voltage Regulation (Cat IVR) provides enhanced system monitoring.

Cooling System

Provides 40⁰C (104⁰F) ambient capability with 500 mg/Nm3 NOx (1g/hp-hr) at 100% continuous rating before derate @ 500m. Variable frequency drive fan controls improve partial load fuel consumption. Energy efficient electric drive fan.

Sound Attenuated Container

Meets 79 dB(A) at 7 meters or below per SAE J1074. 40' ISO high cube container, 9-high stack CSC certified. Service and Personnel doors. External emergency stop buttons on each side ofunit. Externally-accessible controls.

Cat Connect

Remote monitoring for fleet management and asset tracking.

Reduced Environmental Impact

110% spill containment of onboard engine fluids. Positive crankcase fumes ventilation.

Single-Source Supplier

Generator set manufactured in ISO 9001:2000 compliant facility. Package factory designed and production tested.

Worldwide Product Support

Cat® dealers provide extensive post sale support including maintenance and repair agreements. Supported 100% by the Cat dealer with warranty on parts and labor.

Data not available.

Standard Equipment

- Engine

- G3516H, V16, 4-stroke-cycle, gas engine. Operates on 24.10 to 93.95 MJ/Nm3 (615 to 2386 btu/ft3) dry pipeline natural gas. Turbocharged Separate Circuit Aftercooled

- Generator

- Double bearing SR5 1866 Frame, brushless, form wound, 12-lead design, permanent magnet excited, thouree-phase, with Cat IVR, Class H insulation operating at Class F temperature. Stator and Bearing temperature monitoring and anti-condensation space heaters

- Containerized Module

- 40' ISO high cube container, 9-high stack CSC certified. Sound attenuated 79 dB(A) @ 7 m (23 ft) Sound attenuated air intake louvers and 2lockable personnel doors with panic release LH and RH engine service doors integrated intocontainer side walls 3” ANSI flange customer fuel connection

- Cooling

- Standard cooling provides 40⁰C (104⁰F) ambient capability with 500mg/Nm3 NOx at 100% Continuous rating before derate, @ 500m

- Generator Controls And Protection

- On Package EMCP 4.3 Control Panel System Offers engine and generator monitoring and protection, voltage regulation with Cat IVRimproves transient response performance. Controls provide auto paralleling AGC-4 controller, load sharing, VFD control, and primary generator protection for greater versatility, package utilization and monitoring.

- Modes of Operation

- Provides for single unit stand-alone operation,island mode paralleling and load sharing withother power modules, and single unit-to-utilitymode paralleling for base load control

- Lube Oil Make-Up System

- Oil pan-mounted oil level regulator and 114 L (30 gal) oil tank Low level annunciation