Overview

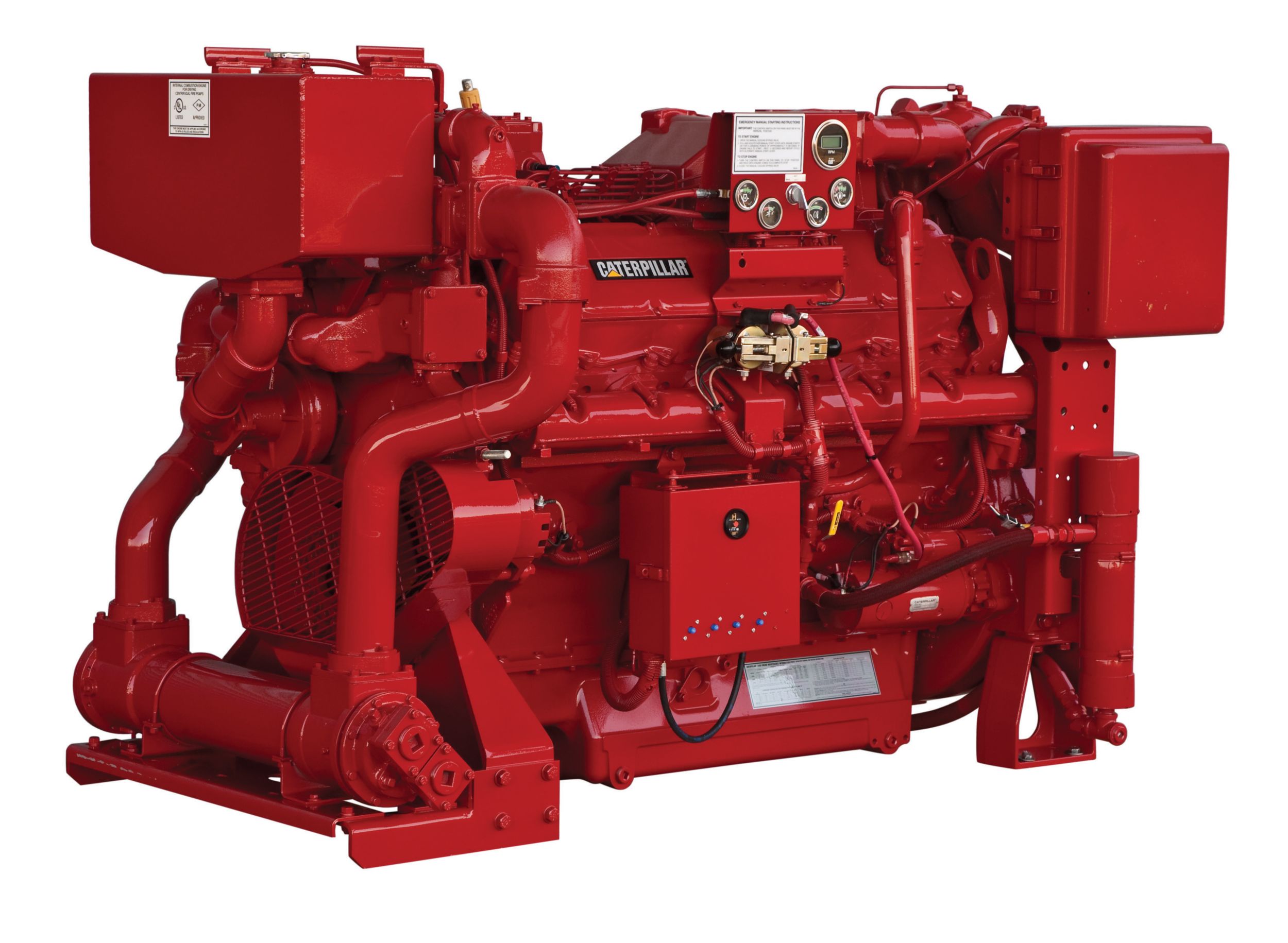

Cat 3412 Industrial Diesel Fire Pump Engine. Ratings: 476-551 bkW (638-739 bhp) @ 1750-2100 rpm are non-certified. Available for global non-regulated areas. FM Approved, UL Listed.

Specifications

| Minimum Rating | — |

| Maximum Rating | — |

| Emissions | Non-certified |

Benefits & Features

Engine Design

Available for global non-regulated areas - FM approved - UL listed - U.S. and Canada - Meets NFPA 20 requirements; Proven reliability and durability; Robust diesel strength design prolongs life and lowers owning and operating costs; Market-leading power density; Core engine components designed for reconditioning and reuse at overhaul

Testing

Every Cat® engine is full-load tested to ensure proper engine performance

World-class Product Support Offered Through Global Cat Dealer Network

More than 2,200 dealer outlets; Cat factory-trained dealer technicians service every aspect of your petroleum engine; Cat parts and labor warranty; Preventive maintenance agreements available for repair before-failure options; S•O•SSM program matches your oil and coolant samples against Caterpillar set standards to determine: Internal engine component condition / Presence of unwanted fluids / Presence of combustion by-products / Site-specific oil change interval

Specifications

| Minimum Rating | — |

| Maximum Rating | — |

| Emissions | Non-certified |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Aspiration | Turbocharged Aftercooled |

| Engine Weight - Net Dry | — |

| Oil Change Interval | — |

| Rotation from Flywheel End | Counterclockwise |

| Flywheel and Flywheel Housing | SAE No. 0 |

| Flywheel Teeth | 151 |

| Lube Oil System - Refill | — |

| Cooling System - Engine | — |

| Length | — |

| Width | — |

| Height | — |

Benefits & Features

Engine Design

Available for global non-regulated areas - FM approved - UL listed - U.S. and Canada - Meets NFPA 20 requirements; Proven reliability and durability; Robust diesel strength design prolongs life and lowers owning and operating costs; Market-leading power density; Core engine components designed for reconditioning and reuse at overhaul

Testing

Every Cat® engine is full-load tested to ensure proper engine performance

World-class Product Support Offered Through Global Cat Dealer Network

More than 2,200 dealer outlets; Cat factory-trained dealer technicians service every aspect of your petroleum engine; Cat parts and labor warranty; Preventive maintenance agreements available for repair before-failure options; S•O•SSM program matches your oil and coolant samples against Caterpillar set standards to determine: Internal engine component condition / Presence of unwanted fluids / Presence of combustion by-products / Site-specific oil change interval

Over 80 Years of Engine Manufacturing Experience

Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable products; Manufacturing of cast engine blocks, heads, cylinder liners, and flywheel housings; Machining of critical components; Complete engine assembly

Web Site

For all your petroleum power requirements, visit www.cat.com/oilandgas

Data not available.

Standard Equipment

- Air Inlet System

- Air cleaner, regular duty with service indicators

- Turbocharged

- Cooling System

- Thermostats and housing

- Jacket water pump, centrifugal

- Heat exchanger installed

- Expansion tank

- Control System

- Charging alternator 24 volt, 35 amp

- Governor control

- Hydra-mechanical governor

- Exhaust System

- Exhaust manifold

- Exhaust elbow, dry. 203 mm (8 in) on all Turbocharged engines and Turbocharged Aftercooled with wet exhaust. 152 mm (6 in) on Turbocharged Aftercooled with dry manifolds.

- Flywheels & Flywheel Housings

- SAE No. 0 flywheel

- SAE No. 0 flywheel housing

- SAE standard rotation

- Fuel System

- Fuel filter

- Fuel transfer pump

- Primary fuel filter

- Fuel priming pump

- Instrumentation

- Instrument panel, LH

- Engine oil pressure gauge

- Fuel pressure gauge

- Water temperature gauge

- Tachometer

- Lube System

- Crankcase breather, top mounted

- Oil cooler

- Oil filler in valve cover and dipstick, both RH

- Lube oil filter

- Rear sump oil pan

- Mounting System

- Supports

- Power Take Off

- Power take-off (PTO) flywheel stub shaft

- Protection System

- Stop-Start System, automatic (compatible with NFPA 20 requirements, able to be energized from either of two battery sources and capable of manual starter actuation)

- Starting System

- 24 volt, LH electric starting motor

- Jacket water heater (6 kW, 240-480 volt)

- General

- Paint: Firepump Red

- Vibration damper and guard

- Lifting eyes