C18 Power Density (60 Hz)Non-Current

C18 Power Density (60 Hz)Overview

Caterpillar is leading the power generation marketplace with Power Solutions engineered to deliver unmatched flexibility, expandability, reliability, and cost-effectiveness.

Specifications

| Minimum Rating | 455 ekW |

| Maximum Rating | 500 ekW |

| Emissions/Fuel Strategy | U.S. EPA Tier 4 Final |

Benefits & Features

Specifications

| Minimum Rating | 455 ekW |

| Maximum Rating | 500 ekW |

| Emissions/Fuel Strategy | U.S. EPA Tier 4 Final |

| Voltage | 480 Volts |

| Frequency | 60 Hz |

| Speed | 1800 RPM |

| Engine Model | C18 ATAAC, I-6, 4-Stroke Water-Cooled Diesel |

| Compression Ratio | 14.5:1 |

| Aspiration | Air to Air Aftercooled |

| Governor Type | Adem™A4 |

| Fuel System | Electronic unit injection |

Benefits & Features

Design Criteria

Design Criteria

The generator set accepts 100% rated load in one step per NFPA 110 and meets ISO 8528-5 transient response.

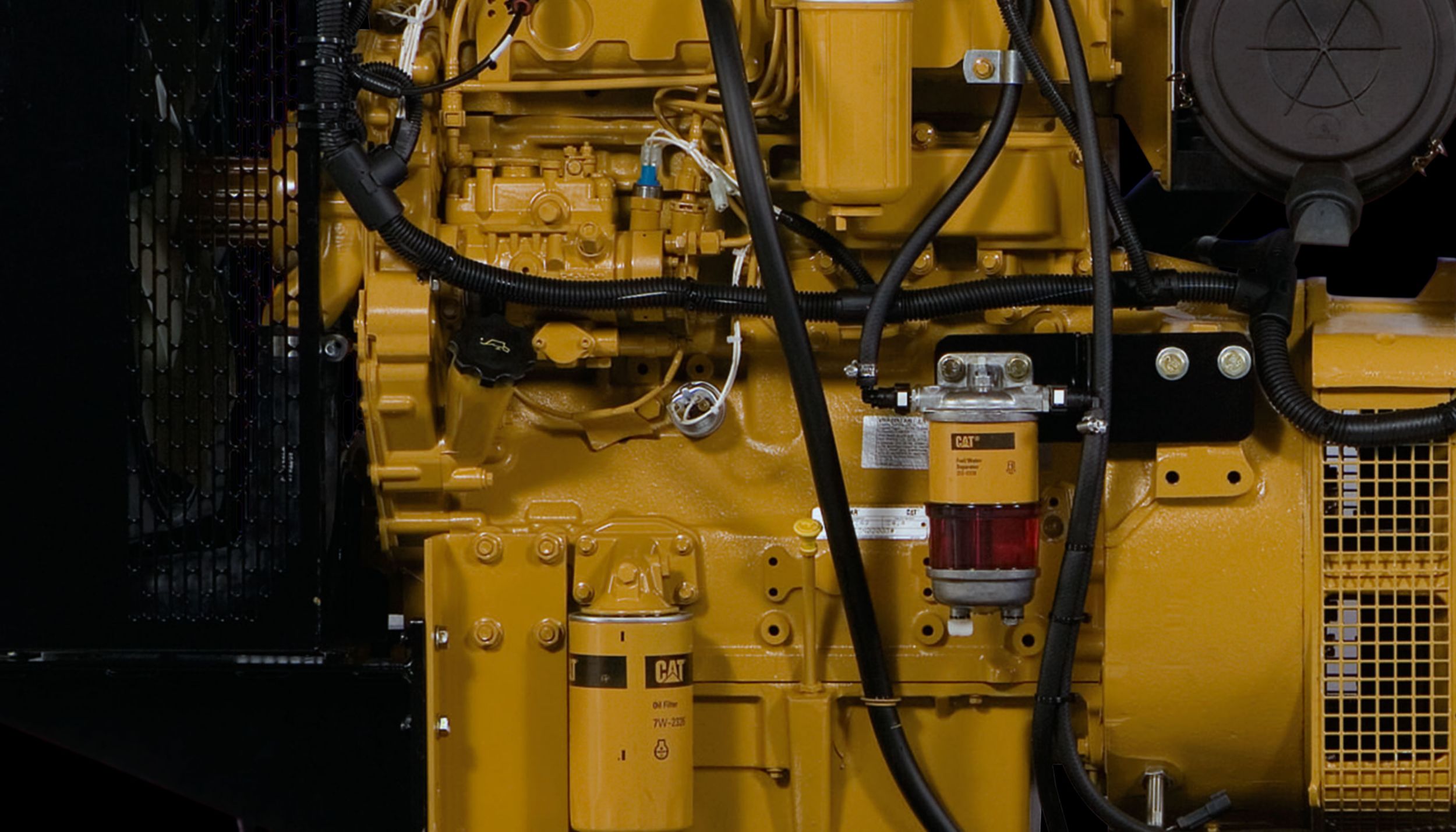

Cat Diesel Engine

Cat Diesel Engine

- Reliable, rugged, durable design

- Field-proven in thousands of applications worldwide

- Four-stroke-cycle diesel engine combines consistent performance and excellent fuel economy with minimum weight

Cat Diesel Tier 4 Final Certified Engine

Cat Diesel Tier 4 Final Certified Engine

- The four cycle Cat diesel engine combines consistent performance with excellent fuel economy and transient response that meets or exceeds ISO 8528-5.

- The engines have been designed and built for a wide range of applications are certified to the US EPA Tier 4 Final emissions requirements. The engines feature a reliable, rugged, and durable design that has been field proven in thousands of applications worldwide from emergency standby installations to continuously operating power plants.

Generator

Generator

- Matched to the performance and output characteristics of Cat engines

- Industry leading mechanical and electrical design

- Industry leading motor starting capabilities

- High Efficiency

EMCP Control Panel

EMCP Control Panel

The EMCP controller features the reliability and durability you have come to expect from your Cat equipment. EMCP4 is a scalable control platform designed to ensure reliable generator set operation, providing extensive information about power output and engine operation. EMCP4 systems can be further customized to meet your needs through programming and expansion modules.

Single-Source Supplier

Single-Source Supplier

Fully prototype tested with certified torsional vibration analysis available

World Wide Product Support

World Wide Product Support

Cat dealers provide extensive post-sale support including maintenance and repair agreements. Cat dealers have over 1,800 dealer branch stores operating in 200 countries. The Caterpillar S•O•S℠ program cost effectively detects internal engine component condition, even the presence of unwanted fluids and combustion by-products

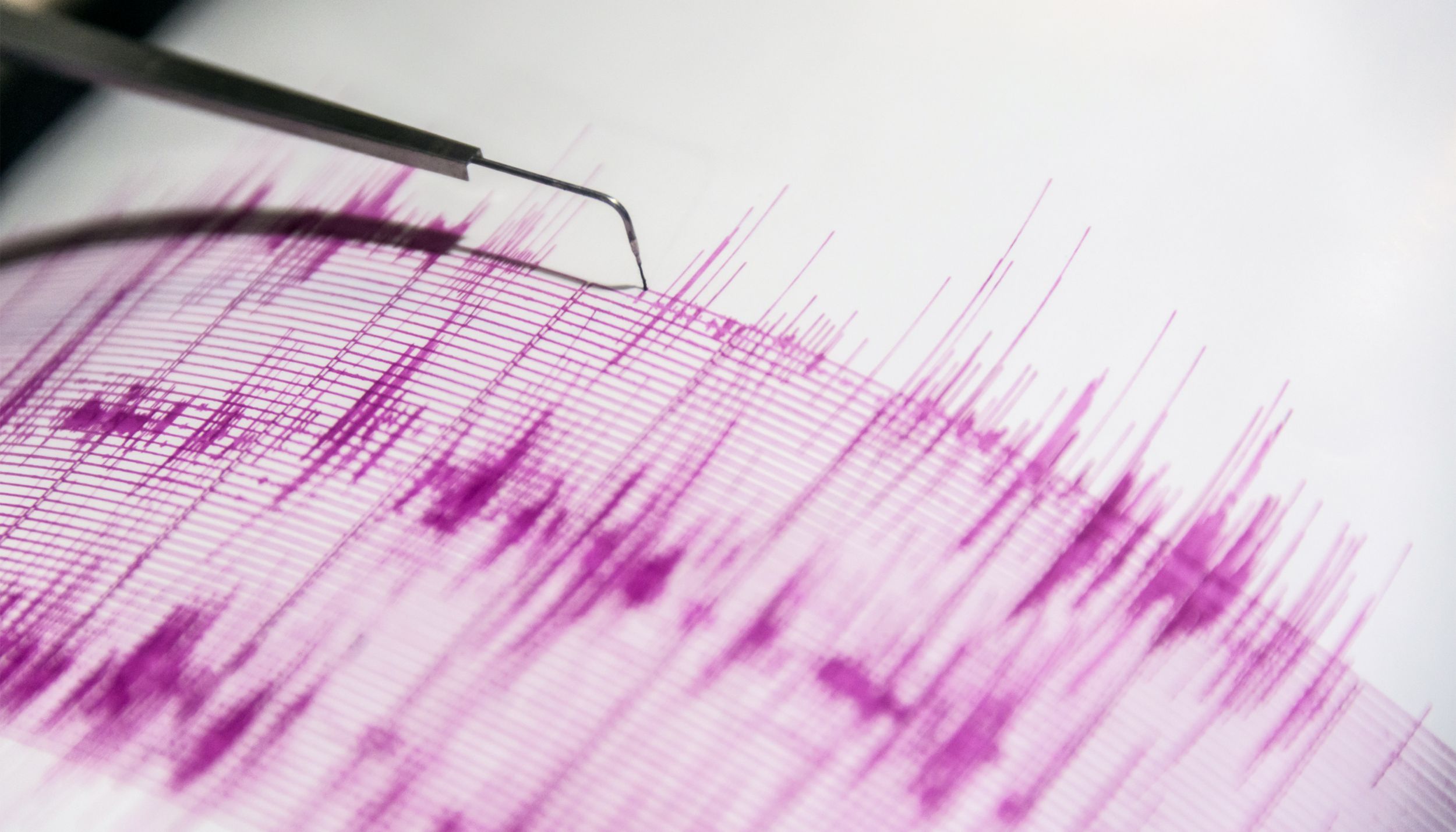

Seismic Certification

Seismic Certification

- Seismic Certification available.

- Anchoring details are site specific, and are dependent on many factors such as generator set size, weight, and concrete strength.

- IBC Certification requires that the anchoring system used is reviewed and approved by a Professional Engineer

- Seismic Certification per Applicable Building Codes: IBC 2000, IBC 2003, IBC 2006, IBC 2009, CBC 2007, CBC 2010

- Pre-approved by OSHPD and carries an OSP-0321-10 for use in healthcare projects in California

Cat Clean Emissions Module (CEM)

Cat Clean Emissions Module (CEM)

- The Tier 4 Final engine has been optimized to work with the Cat CEM.

- The CEM is a reliable, compact, and lightweight system that gives maximum installation flexibility.

- It features a diesel oxidation catalyst for particulate matter (PM) and hydrocarbon (HC) control.

- Selective catalytic reduction (SCR) reduces NOx output and provides integrated sound attenuation.

- The CEM is controlled by a separate dosing module that has been integrated into the standard generator set controls for complete monitoring, protection and closed loop NOx control.

- For more information on the CEM, refer to cut sheet LEHE0359.

UL 2200 / CSA - Optional

UL 2200 / CSA - Optional

- UL 2200 listed packages

- CSA Certified

- Certain restrictions may apply.

- Consult with your Cat® Dealer.

Data not available.

Standard Equipment

- Exhaust System

- Exhaust manifold - dry

- Fuel System

- Fuel cooler

- Fuel priming pump

- Engine fuel transfer pump

- Flexible fuel lines

- Primary fuel filter w/integral water separator and secondary filter

- Generator and Attachments

- Insulation Class H and temperature rise

- Power center, IP22 bottom cable entry

- CIP - generators

- Brushless, self-excited 2/3 pitch, random wound.

- Segregated low voltage (AC/DC) wiring panel

- IP23 Protection

- AREP generator

- Lube System

- Lubricating oil

- Fumes disposal, piped to front of radiator

- Oil drain lines with valve; piped to edge of base

- Oil cooler

- Oil filter and dipstick

- Protection System

- Safety shutoffs for: Higher water temperature - Overspeed - Low oil pressure

- Cooling System

- Coolant level sensor

- Coolant drain line with valve; terminated on edge of base

- Caterpillar extended life coolant

- Thermostats and housing, full open temperature 92 deg C (198 deg F)

- Jacket water pump, gear driven, centrifugal

- Fan and belt guards

- Coolant level sight gauge

- Starting/Charging

- 24-volt electric starting motor

- 24V, 45 Amp Charging alternator

- General

- Operation and maintenance manual pack and OMM storage compartment

- Paint, Caterpillar yellow

- Parts book

- Vibration damper

- Control System

- Programmable protective relaying functions: Generator phase sequence - Over/under voltage (27/59) - Over/under frequency (81 o/u) - Overcurrent (50/51)

- Suitable for use as service equipment label

- Digital indication for: rpm - DC volts - operating hours - Oil pressure (psi, kPa or bar) - Coolant temperature (C or F) - Volts (L-L & L-N), frequency (Hz) - Amps (per phase & average) - Power factor (per phase & average) - kW (per phase & average) - kVA (per phase & average) - kVAr (per phase and average) - kW-hr (total) - kVAr-hr (total)

- EMCP 4.2

- Control panel options: Dust proof control panel - volt free contact - Device server - Ground fault relay

- Controls include: Run/auto/ stop/control - Speed adjust - Voltage adjust - Engine cycle crank - Emergency stop pushbutton

- Communications: Customer data link (RS485 Modbus RTu) - Serial annunciator module data link for local and remote annunciator IVR - Integrated Voltage Regulation (Digital) - EM10 Excitation Module

- Programmable Input / Output: 2 programmable digital inputs - 2 programmable relay outputs (Form A) - 2 programmable relay outputs (Form C)

- Warning/Shutdowns with common LED indication of shutdowns for: Low oil pressure - high coolant temperature - Overspeed - Emergency stop - Failure to start (overcrank) - Low coolant temperature - Low coolant level

- Breaker box mounting location

- Remote annunciators

- Control panel mounting location

- Separation plate

- Optional external analog input

- Local annunciator

- Governing System

- Cat electronic governor (ADEM A4)

- Air Inlet System

- Single element air filter

- Air cleaner - Heavy duty

- Air cleaner - Single element

- Extended Service Coverage

- Silver, Gold and Platinum coverage

- Circuit breakers

- 3 Pole 100% rated

Optional Equipment

- Control System

- Volt free contact

- Ground fault relay

- Separation plate

- Dust proof control panel

- Device server

- Optional external analog input

- Remote E-stop button

- Local annunciator

- Breaker box mounting location

- Remote annunciators

- EMCP 4.4

- Control panel mounting

- Generators and Attachments

- Space heater

- Generator mounting and duct plate

- CIP generators

- AREP generator

- Air Inlet System

- Single element air filter

- Dual element air cleaner

- Certifications

- IBC Certification wind load

- Certificate of Compliance

- Circuit breakers

- Neutral bars

- Power cables

- Motorized single circuit breaker

- Package mounted single circuit breakers

- Dual breakers first circuit breaker (CB1) LS/I package mounted

- Dual breakers first circuit breaker (CB2) LS/I package mounted

- Auxiliary contacts

- Current transformers

- Cooling System

- Aftertreatment guard

- Standard radiator

- Enclosures

- Sound attenuated enclosures

- Exhaust System

- Flange kits

- Exhaust flexible fittings

- Fuel System

- 660 gallon base tank

- Generator Attachments

- Permanent magnet excitation (PMG) generator

- Mounting System

- 5 Gallon spill containment

- Standard base wide

- Overfill prevention valve

- Optional CB shroud

- Locking fuel fill

- Starting / Charging System

- Shore power control group

- Battery disconnect switch

- 10 Amp dual Battery charger

- Jacket water heater

- TESTS

- PGS Test report @ 0.8 power factor

- Generator test report

- 4 Hour factory test (un-witnessed)

- PGS Test report @ 1.0 power factor