June 16, 2025

Specifications

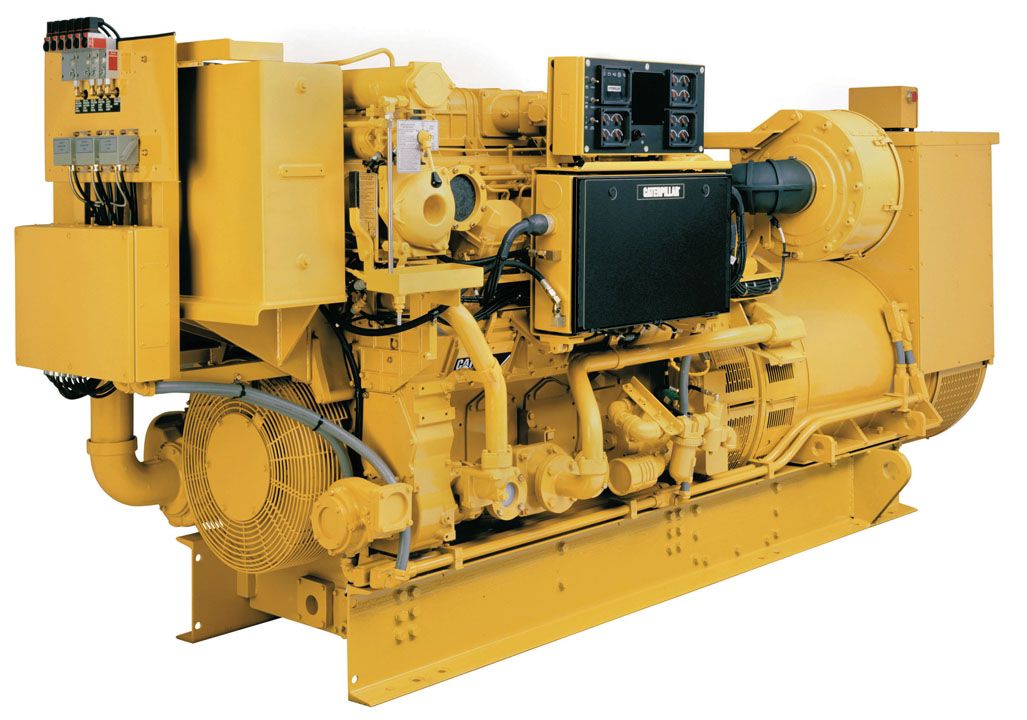

Units:

| Minimum Rating | 590 eKW (738 kVA) |

| Maximum Rating | 910 eKW (1138 kVA) |

| Frequency | 50 hz or 60 hz |

| Speed | 1000 rpm, 1200 rpm, 1500 rpm, 1800 rpm |

| Emissions/Fuel Strategy | IMO I |

| Configuration | Vee 8, 4-Stroke-Cycle Diesel |

| Aspiration | TTA |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Governor Type | Electronic |

| Width | — |

| Weight | 7684 kg (16940 lb) to 8909 kg (19640 lb) |

| Length | 3704 mm (145.8 in) to 4256 mm (167.5 in) |

| Height | 1806 mm (71.1 in) to 1826 mm (71.9 in) |

Benefits & Features

Improved fuel economy

Reduced visible and gaseous emissions

Enhanced diagnostic and monitoring capabilities

Increased rated output with no reduction in reliability

Data not available.

Standard Equipment

- AIR INLET SYSTEM

- Separate Circuit aftercooler core, corrosion resistant coated (air side) Air cleaner, regular duty Dual Turbochargers, 152 mm (6 in) OD straight connection

- CONTROL SYSTEM

- Caterpillar A-III Electronic Engine Control, LH with Electronic Unit Injector Fuel System Rigid Wiring Harness (10 amp DC power required to drive Electronic Engine Control Module)

- COOLING SYSTEM

- Oil cooler Thermostats and housing, full open temperature 92 C (198 F) Jacket water pump, gear driven, centrifugal Auxiliary fresh water pump Expansion tank Auxiliary sea water pump, centrifugal, non-self-priming

- EXHAUST SYSTEM

- Dry gas tight exhaust manifolds with heat shields Dual Turbochargers with watercooled bearings and heat shields Exhaust outlet, vertical, 203 mm (8 in) round flanged outlet

- FLYWHEELS & FLYWHEEL HOUSINGS

- Flywheel, SAE No. 00, 183 teeth Flywheel housing, SAE No. 00

- FUEL SYSTEM

- Fuel filter, RH, with service indicators Fuel transfer pump Electronically Controlled Unit Injectors

- INSTRUMENTATION

- Overspeed shutdown notification light, Emergency stop notification light

- Graphical Unit (Marine Power Display) for analog or digital display of:

- LUBE SYSTEM

- Crankcase breather, Top mounted Oil filter, RH Oil filler and dipstick, RH 500 hours sump oil pan Oil pump, gear type

- MOUNTING SYSTEM

- Rails, engine mounting, engine length, industrial type, 254 mm (10 in), C-channel

- POWER TAKE-OFFS

- Accessory drive Lower RH, Lower LH Front housing, Two-sided

- PROTECTION SYSTEM

- A-III Electronic Monitoring System provides customer programmable engine de-ration strategies to protect against adverse operating conditions

- Emergency stop push button (located in Electronic Instrument Panel) Safety shutoff protection:

- GENERAL

- Vibration damper and guard Paint, Caterpillar Yellow engine with black rails. Lifting eyes

- NOTE: 1. Engines for heat exchanger cooling do NOT include heat exchanger. 2. When used with competitive generator, a TVA is recommended. An alternative vibration damper may be required. 3. Engine is wired for auto start stop.

Optional Equipment

- AIR INLET SYSTEM

- Remote Air Inlet Adapters

- CHARGING SYSTEM

- Battery Chargers

- Charging Alternators

- CONTROL SYSTEM

- Load Sharing module

- Local speed throttle control

- COOLING SYSTEM

- Water level switch gauge

- Coolant level sensors

- Connections

- Radiator cooling conversion

- Keel Cooling Conversions

- Heat exchangers

- Auxiliary water pumps

- Sea water pump removal

- Air separator

- EXHAUST SYSTEM

- Horizontal Exhaust

- Exhaust outlet

- Flexible fittings

- Elbows

- Flanges

- Flange and exhaust expanders

- Mufflers

- FUEL SYSTEM

- Fuel Cooler

- Fuel priming pumps

- Flexible fuel lines

- Rigid Fuel Lines

- Primary fuel filter

- Fuel filters

- Duplex fuel filters

- Fuel level switch

- GENERATORS AND GENERATOR ATTACHMENTS

- 1500/1800 RPM, 1000/1200 RPM, low voltage conection, generator conversation, low voltage extension box, RFI filter, bearing temperature detectors (RTD), manual voltage control, air filter

- INSTRUMENTATION

- PL1000T Communication Module

- PL1000E Communication Module

- Customer Interface Box

- Thermocouples

- Remote panel display

- Remote cylinder temperature display

- LUBE SYSTEM

- Oil Pan

- Oil pan accessories

- Sump pumps

- Oil filters

- Lubricating oil

- Lube system

- MOUNTING SYSTEM

- Rails

- POWER TAKE-OFFS

- Flywheel Guard

- Flexible Coupling

- Coupling Hub

- Upper Left Hand Front Location

- Upper Left Hand Rear Location

- Upper Right Hand Front Location

- Upper Right Hand Rear Location

- Lower Left Hand Front Location

- Lower Left Hand Rear Location

- Front Housing Accessory Drives

- Upper LH Accessory Drive

- Upper RH Accessory Drive

- Front Power Take-offs

- Crankshaft Pulleys

- Damper Guard Removals

- PROTECTION SYSTEM

- Air inlet shutoffs

- Switches and contactors

- Explosion relief valve

- OIL TEMP SENSOR

- INTAKE MANIFOLD TEMP SENSOR

- STARTING SYSTEM

- Starting motors or barring divice

- Air starting motors options

- Starting aids

- Battery sets - 24 volt - Dry

- Battery rack

- GENERAL

- Tool set

- Caterpillar datalink wire