M 34 DFNon-Current

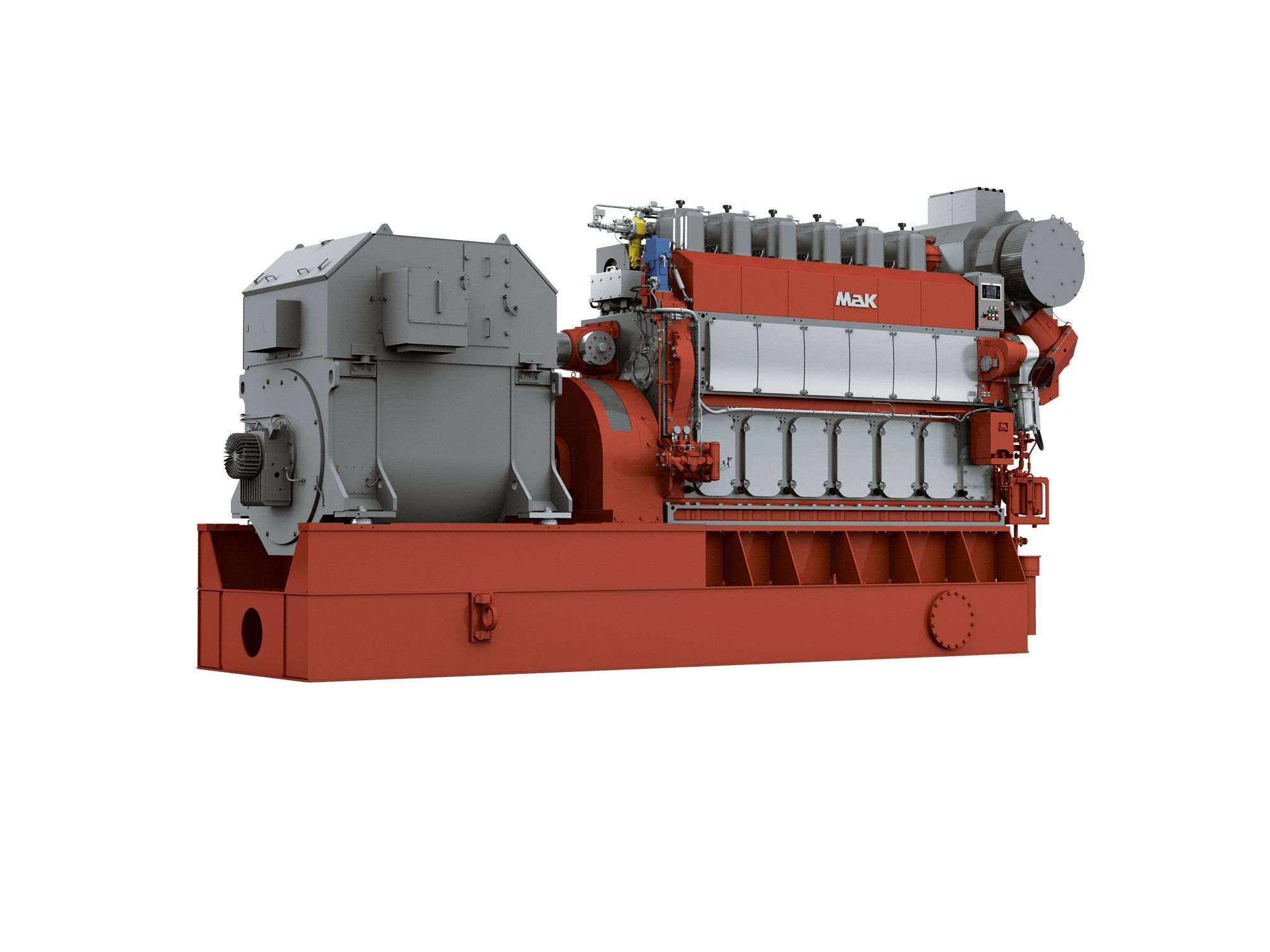

M 34 DF Generator SetOverview

Caterpillar Motoren designed the M 34 DF based on the reliable M 32 C engine series. It will be capable of operating on multiple fuels without sacrificing the typical MaK marine engine attributes. The M 34 DF will be capable of running on Liquid Natural Gas (LNG) as an alternative to the expensive low sulfur Marine Diesel Oil (MDO) or large and complex scrubber installations for ECA operation as of 2015. High efficiency and proven reliability make the M 34 DF an excellent generator set. Due to selected operation profiles and low diesel fuel costs, the M 34 DF is a preferred generator set regarding cost of operation.

Specifications

Units:

| Minimum Rating | 2934 kWe (3672 kVA) |

| Maximum Rating | 4574 kWe (5724 kVA) |

| Configuration | 6,8,9 Cylinder |

Benefits & Features

June 16, 2025

Specifications

Units:

| Minimum Rating | 2934 kWe (3672 kVA) |

| Maximum Rating | 4574 kWe (5724 kVA) |

| Emissions/Fuel Strategy | IMO III |

| Configuration | 6,8,9 Cylinder |

| Bore | — |

| Stroke | — |

| Swept Volume | — |

| Height | 4567 - 4770 mm (179.8 - 187.8 in) |

| Weight | 73.0 - 98.0 t (160937 - 216053 lbs) |

| Width | 2600 mm (102.4 in) |

| Length | 9566 - 11156 mm (376.6 - 439.2 in) |

Benefits & Features

Ease of installation

Reliable Operation

Ease of maintenance

Easy component accessibility

Data not available.

Standard Equipment

- Air Inlet System

- Air intake silencer / filter

- Control System

- Load sharing Unit

- Modular Alarm Control Protection System (MACS)

- Speed governor

- Cooling System

- Electric cooling water preheater

- HT cooling water pump (engine driven)

- 2-stage charge air cooler

- Exhaust System

- Exhaust gas expansion joint

- Exhaust gas insulated manifolds

- Turbocharger at flywheel / counter-flywheel end

- Fuel System

- Fuel circulating pump (electric driven / for MDO/MGO only)

- Fuel indicator filter

- Fuel pressure valve (separate / for MDO/MGO only)

- Gas System

- Gas valve unit

- Instrumentation

- Control push buttons and lamps

- Emergency stop lever

- Local control panel

- Pressure and temperature indicator

- Lube System

- Dry sump

- Lube oil plate cooler (separate)

- Lube oil pump (engine driven)

- Lube oil safety filter

- Lube oil self-cleaning filter

- Pressure regulating valve

- Mounting System

- High flexible coupling

- Rigid mounting

- Starting System

- Electrical barring device

- Starting air valve

- General

- Torsional Vibration Calculation (TVC)

Optional Equipment

- Air Inlet System

- Air inlet shut-off valve

- Air intake transition piece

- Expansion joint

- Silencer / filter

- Control System

- Engine alarm system

- Remote control system

- Remote indicators (start air pressure, engine speed, etc.)

- Starter for electric driven pumps

- 24 DC UPS

- Cooling System

- Cooling water preheater steam / thermal oil / electrical

- Cooling water piping for generator cooling on base frame

- Cooling water piping for lubricating oil cooler on base frame

- FW/SW plate cooler

- HT cooling water pump (electric driven)

- LT cooling water pump (electric driven)

- Sea water cooling pump (electric driven)

- Temperature control valve

- Exhaust System

- Exhaust gas ventilation module

- Silencer (with or without spark arrester)

- Fuel System

- Fuel oil cooler

- HFO final preheater

- HFO pressure regulating valve

- HFO self-cleaning automatic filter

- HFO supply and booster pumps (electrical driven)

- HFO treatment and supply modules

- HFO viscosity control device

- Mixing tank

- Gas System

- Gas flowmeter

- LNG vaporizing unit

- Lube System

- Lube oil centrifuge

- Lube oil pump (electrical driven)

- Lube oil treatment and combined modules

- Pre-lubricating oil pump (electrical driven)

- Temperature control valve

- Wet sump with dip stick

- Mounting System

- Double resilient mounting

- Flexible pipe connections

- Resilient mounting

- Propulsion System

- Control system

- Thrusters

- Starting System

- Starting air compressor

- Starting air receiver

- General

- Engine PTO coupling

- Flywheel cover

- PTO alternator

- PTO shaft on counter-flywheel side

- Reduction gear

- Reduction gear PTO coupling