Overview

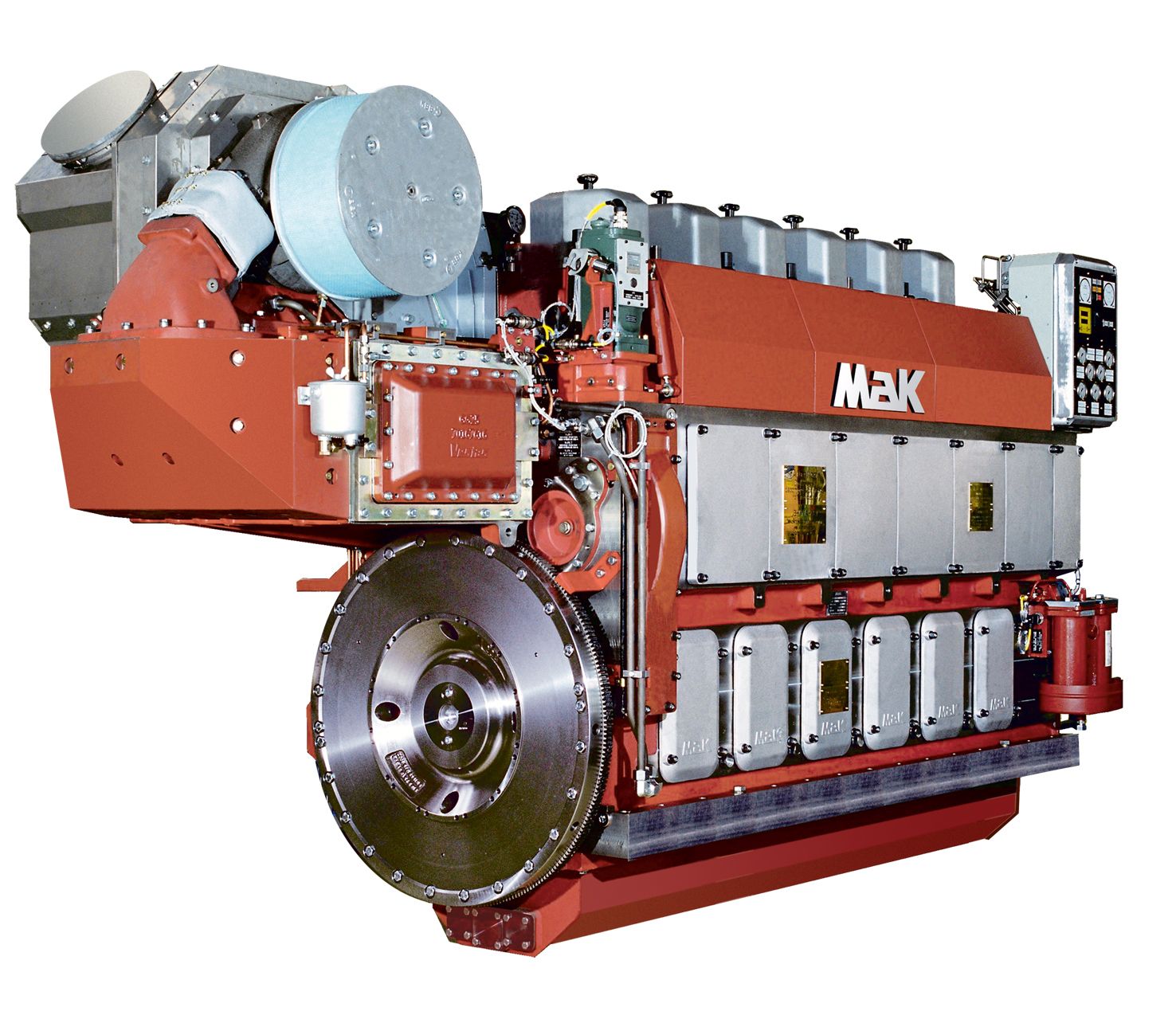

Developed and designed in response to special requirements of marine applications, the M 20 C is characterized by high reliability and economy. These features help to explain the continued high market demand for the M 20 C. The long-stroke design principle is the backbone of an excellent combustion process with low fuel and lubricating oil consumption, as well as low NOx emission. The M 20 C engine is SOLAS compliant. Its intelligent simplicity means high functional integration of fewer components. Fewer components mean greater reliability and easier maintenance. Overall, this leads to outstandingly low operating costs and rapid returns on investment. Reliability and ease of maintenance are convincing arguments in favor of the engines of this series.

Specifications

| Power Range | 1020-1800 kW |

| Speed Range | 900-1000 rpm |

| Emissions | IMO II / IMO III with SCR |

Benefits & Features

Emissions

For IMO III emissions the MaK M 20 C is delivered with a Scheme A factory certified SCR solution and a factory EIAPP certificate, simplifying installation and commissiong work significantly. Caterpillar's SCR technology minimizes total cost of ownership by cutting the diesel and urea expenses by offering the lowest total fluid consumption at optimized engine and SCR life time.

Engine with high safety level

The M 20 C is an engine with a high safety level. This applies not only to those special internal design features which guarantee long component life and high availability but also to safety in the area around the engine. As a result, SOLAS regulations are strictly and consistently observed. Explosion protection cover for the cylinder/crankcase housing and cladding of the complete fuel and exhaust gas system in stainless steel are part of an overall SOLAS safety concept.

HFO/MDO - Long TBO and lifetime

Long maintenance intervals and the life of components are the basis for low operating costs.

Specifications

| Power Range | 1020-1800 kW |

| Speed Range | 900-1000 rpm |

| Emissions | IMO II / IMO III with SCR |

| Aspiration | Turbocharged |

| Bore | — |

| Stroke | — |

| Rotation from Flywheel End | Counterclockwise/Clockwise |

| Configuration | Inline 6,8,9 Cylinder |

| Swept Volume | — |

| Minimum Dry Weight | — |

| Minimum Length | — |

| Maximum Length | — |

| Minimum Height | — |

| Maximum Height | — |

| Minimum Width | — |

| Maximum Width | — |

Benefits & Features

Emissions

For IMO III emissions the MaK M 20 C is delivered with a Scheme A factory certified SCR solution and a factory EIAPP certificate, simplifying installation and commissiong work significantly. Caterpillar's SCR technology minimizes total cost of ownership by cutting the diesel and urea expenses by offering the lowest total fluid consumption at optimized engine and SCR life time.

Engine with high safety level

The M 20 C is an engine with a high safety level. This applies not only to those special internal design features which guarantee long component life and high availability but also to safety in the area around the engine. As a result, SOLAS regulations are strictly and consistently observed. Explosion protection cover for the cylinder/crankcase housing and cladding of the complete fuel and exhaust gas system in stainless steel are part of an overall SOLAS safety concept.

HFO/MDO - Long TBO and lifetime

Long maintenance intervals and the life of components are the basis for low operating costs.

Complete engine

The engine is marketed with a standardized range of installed pumps and filters. Inter faces for fuel, lubricating oil and cooling water systems are located at the opposite end to the crankshaft coupling for ease of connection.

Reliable energy supply

The complete diesel generating set is notable for its ease of installation, reliable operation, ease of maintenance and good component accessibility. The basis is formed by the rigid base frame as foundation of the engine and alternator with integrated oil sump, large oil volume and universal equipment for both HFO and MDO operation.

Complete propulsion systems

System responsibility and supply from a single source, Accurately matched interfaces, Coordinated delivery data control

Data not available.

Standard Equipment

- Air Inlet System

- Air intake silencer / filter

- Control System

- Load Sharing Unit (for multiple engine plant only)

- Protection panel (emergency stop, override, reset push buttons)

- Protection System

- Serial Link Interface (MODbus RTU/canbus)

- Speed governor

- Start/Stop panel

- Cooling System

- Charge air cooler

- Electronic cooling water preheater

- HT cooling water pump (engine driven)

- LT cooling water pump (engine driven)

- Exhaust System

- Exhaust gas expansion joint

- Exhaust gas insulated manifolds

- Turbocharger at flywheel side

- Fuel System

- Fuel circulating pump (attached / for MDO/MGO only)

- Fuel indicator filter

- Fuel pressure valve (separate / for MDO/MGO only)

- Instrumentation

- Control push buttons and lamps

- Emergency stop lever

- Local Control Panel

- Pressure and temperature indicator

- Lube System

- Dry sump

- Lube oil cooler

- Lube oil pump (engine driven)

- Lube oil self-cleaning filter

- Pressure regulating valve

- Mounting System

- High flexible coupling

- Rigid mounting

- Starting System

- Air starting motor

- Manual barring device

- General

- Lifting device (rental)

- Torsional Vibration Calculation (TVC)

Optional Equipment

- Air Inlet System

- Air inlet shut-off valve

- Air intake transition piece

- Expansion joint

- Silencer / filter

- Control System

- Electronic speed governor

- Engine alarm system

- Remote control system

- Remote indicators (start air pressure, engine speed, etc.)

- Starter for electroc driven pumps

- 24 DC UPS

- Cooling System

- FW/SW plate cooler

- HT cooling water pump (electric driven)

- LT cooling water pump (electric driven)

- Sea water cooling pump (electric driven)

- Steam / thermal oil cooling water preheater

- Temperature control valve

- Exhaust System

- Silencer (with or without spark arrester)

- Turbocharger at counter-flywheel side

- Fuel System

- Fuel oil cooler

- HFO treatment and supply modules

- HFO supply and booster pumps (electrical driven)

- HFO self-cleaning automatic filter

- HFO pressure regulating valve

- HFO final preheater

- HFO viscosity control device

- Mixing tank

- Lube System

- Lube oil centrifuge

- Lube oil pump (electrical driven)

- Lube oil treatment and combined modules

- Pre-lubricating oil sump (electrical driven)

- Wet sump

- Mounting System

- Flexible pipe connections

- Resilient mounting

- Starting System

- Starting air receiver

- Starting air compressor

- General

- Cat Propulsion Systems

- Engine PTO coupling

- PTO alternator

- PTO shaft on counter-flywheel side

- Reduction gear

- Reduction gear PTO coupling