Overview

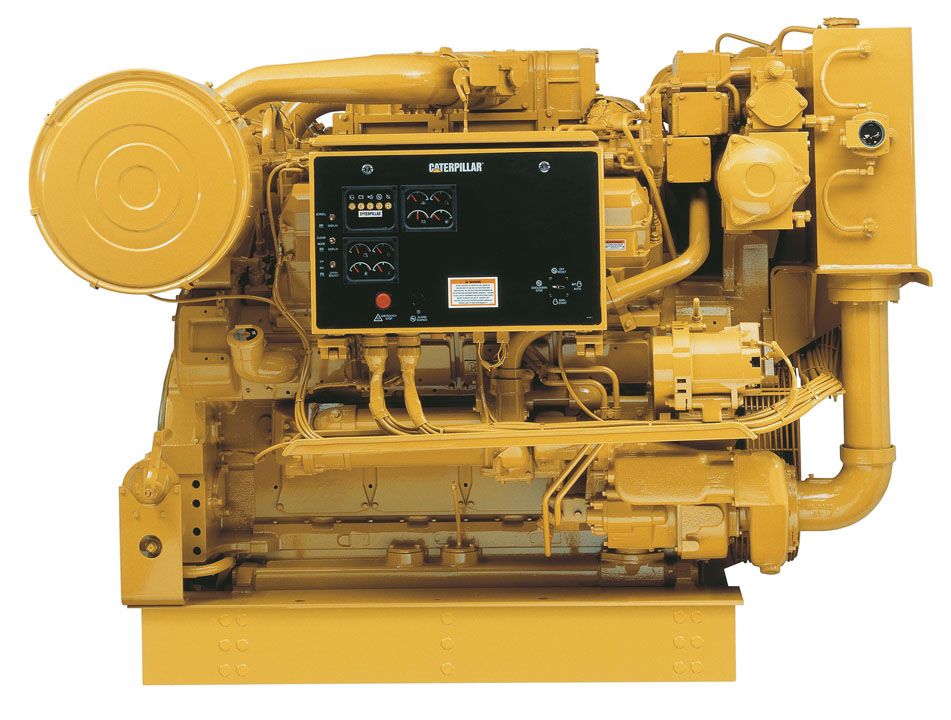

The 3508B marine engine features ratings from 578 bkw (786 mhp) to 1118 bkw (1521 mhp). Highlights of this marine engine include the Advanced Diesel Engine Management System II, Control Monitoring Protection System, Customer Communication Module, and Digital Voltage Regulator.

Specifications

| Power Range | 775-1500 bhp (578-1118 bkW) |

| Speed Range | 1200-1925 rpm |

| Emissions | IMO I |

Benefits & Features

Electric Unit Injector Fuel System

Electronic Unit Injector fuel system featuring 10-20 percent higher injection pressure than other 3500 Family engines

Caterpillar ADEM II Electronic Engine Control/Monitoring System

Caterpillar ADEM II Electronic Engine Control/Monitoring System that provides infinitely variable injection timing and a state-of-the-art monitoring and protection system with self-diagnosing electronic sensors

“Deep Crater/Low Crevice Volume” Two-Piece Articulated Piston Design

“Deep Crater/Low Crevice Volume” two-piece articulated piston design with forged steel crown and cast aluminum skirt that enhance combustion efficiency to provide improved fuel efficiency and lower levels of gaseous and visible emissions

Specifications

| Power Range | 775-1500 bhp (578-1118 bkW) |

| Speed Range | 1200-1925 rpm |

| Emissions | IMO I |

| Aspiration | TTA |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Rotation from Flywheel End | Counterclockwise or clockwise |

| Configuration | Vee 8, 4-Stroke-Cycle Diesel |

| Minimum Dry Weight | — |

| Height | — |

| Width | — |

| Length | — |

| Maximum Dry Weight | — |

Benefits & Features

Electric Unit Injector Fuel System

Electronic Unit Injector fuel system featuring 10-20 percent higher injection pressure than other 3500 Family engines

Caterpillar ADEM II Electronic Engine Control/Monitoring System

Caterpillar ADEM II Electronic Engine Control/Monitoring System that provides infinitely variable injection timing and a state-of-the-art monitoring and protection system with self-diagnosing electronic sensors

“Deep Crater/Low Crevice Volume” Two-Piece Articulated Piston Design

“Deep Crater/Low Crevice Volume” two-piece articulated piston design with forged steel crown and cast aluminum skirt that enhance combustion efficiency to provide improved fuel efficiency and lower levels of gaseous and visible emissions

Larger diameter Camshaft

Larger diameter (98 mm vs. 92 mm bore) camshaft for higher injection pressures, shorter injection durations, and less gear train torsional vibration

Fuel Injection System

Strengthened fuel injection actuation system and rear gear train to maintain reliability and durability while providing higher injection pressures

Center-Mounted Low Inertia Turbochargers

Center-mounted low inertia turbochargers (four on 3512B and 3516B; two on 3508B) on EPG models

Rear Mounted Turbochargers

Dual rear mounted turbochargers on all marine configurations

Separate Circuit or Sea Water Aftercooling

Separate circuit or sea water aftercooling to supply the optimum temperature air to the combustion chamber to reduce emissions and fuel consumption and maximize power output

Streamlined Intake and Exhaust Manifolds

Streamlined intake and exhaust manifolds to reduce parasitic pumping losses and increase combustion efficiency

Thermo-laminated heat shields

Thermo-laminated heat shields on all marine configurations to maintain surface temperatures below Marine Classification Society regulations and to retain more exhaust gas energy for increased turbocharger performance

Electronic instrument panel

Electronic instrument panel with eight analog gauges, 10 LEDs, and one LCD read-out to display engine operating conditions and fault codes

Pin-type connector for easy connection of Caterpillar Engine Technician electronic service tool

Pin-type connector for easy connection of Caterpillar Engine Technician electronic service tool which delivers superior diagnostic capability to determine exact causes of engine faults

Formed lastomeric Seals

Formed elastomeric seals replace gaskets on rocker arm bases eliminating gasket relaxation to maintain consistent dimensions for valve lash and injection settings and nuisance-type oil leaks.

Redesigned aftercooler-to-intake manifold joints

Redesigned aftercooler-to-intake manifold joints that use formed elastomeric seals and substantially fewer fasteners to give superior sealing characteristics and easier serviceability

Data not available.

Standard Equipment

- Fuel System

- Fuel filter, RH, with service indicators.

- Fuel transfer pump.

- Electronically controlled init injectors

- Instrumentation

- Graphical Unit (Marine Power Display)

- Lube System

- Crankcase breather, Top mounted

- Oil filter, RH, with service indicators

- Oil filler and dipstick, RH

- Standard sump oil pan (500 Hour oil change interval)

- Oil pump, gear type

- Mounting System

- Rails, engine mounting, ledge type, 203 mm x 203 mm (8 in x 8 in)

- Power Takeoffs

- Accessory drive

- Front housing, two-sided

- Protection System

- A4 ECU Electronic Monitoring System provides customer programmable engine de-rate strategies to protect against adverse operating conditions

- AIII Electronic Monitoring System provides customer programmable engine de-ration strategies to protect against adverse operating conditions

- Emergency stop push button (located in Electronic Instrument Panel) Safety shutoff protection:

- General

- Vibration damper and guard

- Lifting eyes

- Paint, Caterpillar Yellow engine with black rails

- NOTE: Engines for heat exchanger cooling do NOT include heat exchanger.

- Flywheel and Flywheel Housing

- Flywheel, SAE No. 0, 151 teeth.

- Flywheel housing, SAE No. 0.

- Air Inlet System

- Separate circuit aftercooler core, corrosion resistant coated (air side)

- Air cleaner, regular duty

- Dual turbochargers, 152 mm (6 in) OD straight connection

- Control System

- Dual Caterpillar A-III Electronic Engine Control, LH with Electronic Unit Injector Fuel System

- Rigid Wiring Harness (10 amp DC power required to drive Electronic Engine Control Module)

- Cooling System

- Oil cooler

- Thermostats and housing, Full open temperature 92 C (198 F)

- Jacket water pump, gear driven, centrifugal

- Auxiliary fresh water pump with SCAC engines

- Auxiliary sea water pump, Centrifugal, Non-self-priming

- Expansion tank

- Exhaust System

- Dry gas tight exhaust manifolds with heat shields.

- Dual turbochargers with watercooled bearings and heat shield.

- Exhaust outlet, vertical, 203 mm (8 in) round flanged.

Optional Equipment

- Charging System

- Battery Charger, 10 amp

- Charging Alternators

- Cooling System

- Water Level Switch Gauge

- Coolant Level Sensors

- Connections

- Keel Cooling Conversions

- Heat Exchangers

- Auxiliary Water Pumps

- Sea Water Pump Removal

- Coolant Shunt Tanks

- Air Separator

- Marine Gear Cooling

- Instrumentation

- PL1000T Communication Module

- Customer Interface

- Thermocouples

- Remote Panel Display

- Remote Cylinder Temperature Display

- Pilot House Instrument Panels

- Marine Gear Sensors

- Engine Vision Display System

- Mounting System

- Engine Supports

- Vibration Isolators

- Power Take-Offs

- Front Housing Accessories

- Flexible Coupling and Guards

- Upper Left Hand Front Location:

- Upper Right Hand Front Location:

- Upper Right Hand Rear Location:

- Lower Left Hand Front Location:

- Lower Left Hand Rear Location:

- Front Housing Accessory Drives

- Upper LH Accessory Drive

- Upper RH Accessory Drive

- Front Power Take Offs

- Crankshaft Pulleys

- Damper Guard Removals

- Air Inlet System

- Remote Air Inlet Adapters

- Control System

- Throttle Position Sensor

- Throttle Position Signal Conv.

- Throttle Position Sensor Removal

- Local Speed Throttle Control

- Throttle Synchronization

- Exhaust System

- Exhaust Outlet

- Flexible Fittings

- Elbows

- Flanges

- Flange and Exhaust Expanders

- Mufflers

- Lube System

- Oil Pan

- Oil Pan Accessories

- Sump Pumps

- Lubricating Oil

- Protection System

- Air Inlet Shutoffs

- Switches and Contactors

- Explosion Relief Valve

- Sensors

- Special Appearance

- Special Appearance Packages with Chrome Covers

- Chrome Plated Relief Valves

- Black Air Cleaners

- Yacht Class Finish

- Starting System

- Starting Motors or Barring Device

- Air Starting Motor Options:

- Starting Aids

- Battery Sets - 24 Volt - Dry

- Battery rack

- General

- Tool set

- Caterpillar datalink wire

- Paints

- Special Paints

- Packing

- Shrink Wrap Protection

- Storage Preservation with Glycol Solution/Vapor Corrosion Inhibitor

- Storage Preservation with Vapor Corrosion Inhibitor

- Export Packaging