Overview

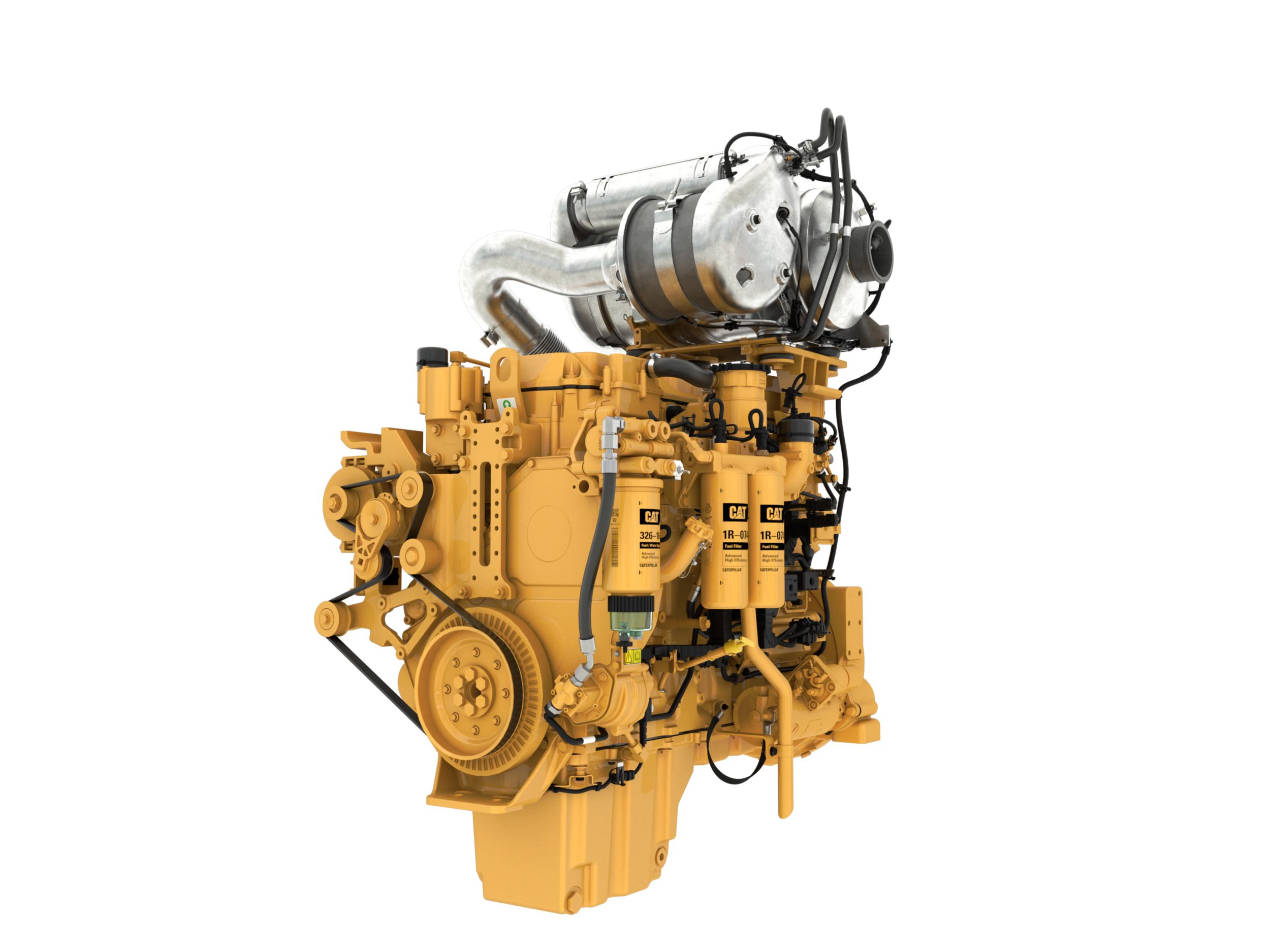

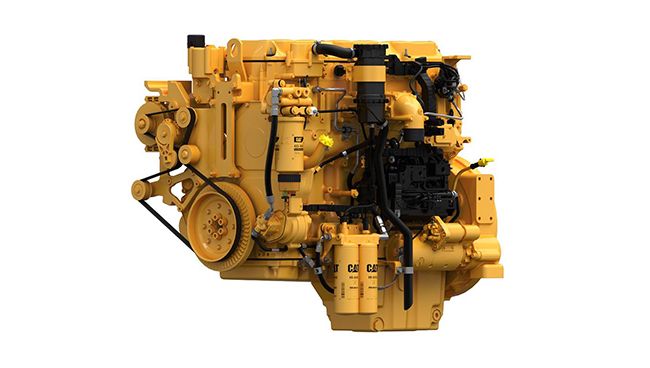

The Cat® C13B engine supplies remarkable power and torque in a smaller, lighter engine package. With a aftertreatment that is 65% smaller and 54% lighter than its current equivalent and over 34 kW/L of power density, the C13B is designed to allow OEMs to downsize their engine platforms, lower installation costs and maximize uptime by providing long life in the toughest applications.

Specifications

| Maximum Power | — |

| Maximum Torque | — |

| Emissions | EU Stage V, U.S. EPA Tier 4 Final, Korea Stage V, Japan 2014, China NRIV |

Benefits & Features

Installation

With a 65% reduction in size and 63% in weight from its previous engine equivalent, the Cat C13B is unparalled in supporting engine downsizing without an impact to overall performance. And with an absence of an EGR, the C13B provides a simplfied installation process, saving OEMs valauble time and costs.

Advanced Features

Offering peak performance across a wide range of speed, the Cat C13B is optimized to perform at its best no matter what surprises the job site brings. And with 20% more power and 19% more torque than its predecessor engine, the C13 has never been more ready to take on the tough challenges operators meet of every day.

Ideal Applications

Industrial, agricultural and construction applications such as: Compressors • Trenchers • Chippers • Grinders • Irrigation equipment • Bore rigs • Drill rigs • Pumps • Hydraulic power units

Specifications

| Maximum Power | — |

| Maximum Torque | — |

| Rated Speed | 1800-2100 rpm |

| Minimum Power | — |

| Emissions | EU Stage V, U.S. EPA Tier 4 Final, Korea Stage V, Japan 2014, China NRIV |

| Engine Configuration | In-Line 6 |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Compression Ratio | 15.8:1 |

| Aspiration | Turbocharged-Aftercooled (TA) |

| Combustion System | Direct Injection |

| Rotation from Flywheel End | Counterclockwise |

| Aftertreatment | DOC+DPF+SCR |

| Length | — |

| Width | — |

| Height | — |

| Weight - Net Dry - Basic Operating Engine Without Optional Attachments | — |

| Length | — |

| Width | — |

| Height | — |

| Weight | — |

Benefits & Features

Installation

With a 65% reduction in size and 63% in weight from its previous engine equivalent, the Cat C13B is unparalled in supporting engine downsizing without an impact to overall performance. And with an absence of an EGR, the C13B provides a simplfied installation process, saving OEMs valauble time and costs.

Advanced Features

Offering peak performance across a wide range of speed, the Cat C13B is optimized to perform at its best no matter what surprises the job site brings. And with 20% more power and 19% more torque than its predecessor engine, the C13 has never been more ready to take on the tough challenges operators meet of every day.

Ideal Applications

Industrial, agricultural and construction applications such as: Compressors • Trenchers • Chippers • Grinders • Irrigation equipment • Bore rigs • Drill rigs • Pumps • Hydraulic power units

Total Cost of Ownership

The Cat C13B utilizes several technologies to deliver the lowest possible fluid consumption, including an overall fuel savings of 6% when compared to the C13 engine. And thanks to Caterpillar-patented technology the EGR has been eliminated, oil intervals are rated at 500 hours and 5,000 hours for ash services, helping OEMs and operators save on parts and service costs over the lifetime of the engine.

Cat Dealer Product Support

No matter where in the world the Cat C13B is, it’s backed by the reliable and extensive support the Cat dealer network offers across 192 countries. And for even more peace of mind, your Cat engine comes under warranty. See your Cat dealer for details.

Safety

At Caterpillar, safety is a prioirty. It's why we put all our engines through rigorous rounds of testing and validation—including more than 120 mililon off-highway hours for the Cat C13B. We make our engines reliable, so operators can focus on keeping their work site safe, secure and in service.

Data not available.

Standard Equipment

- Air Inlet System

- Turbocharged

- Air-to-Air Aftercooled

- Front or rear exhaust configurations available

- Control System

- Electronic control system

- Over-foam wiring harness

- Automatic altitude compensation

- Power compensated for fuel temperature

- Configurable software features

- Engine monitoring system SAE J1939 broadcast and control

- Integrated Electronic Control Unit (ECU)

- Remote fan control

- Cooling System

- Vertical or RH thermostat outlet

- Centrifugal water pump

- Guidance on cooling system design available through your dealer to ensure equipment reliability

- Flywheels and Flywheel Housing

- Available SAE No. 1 power take-off with optional SAE B or SAE C power take-off drives. Engine power can also be taken from the front of the engine with optional attachments.

- Fuel System

- Mechanical Electronic Unit Injector fuel system (MEUI-C)

- Primary fuel filter

- Secondary and tertiary fuel filters

- Fuel transfer pump

- Electronic fuel priming

- Lube System

- Open crankcase ventilation system

- Oil cooler

- Oil filler

- Lube oil filter

- Oil dipstick

- Gear driven oil pump

- Choice of front, rear or center sumps

- Open crankcase ventilation system with fumes disposal (OCV filter system required for EU Stage V certification engines)

- Power Take Off (PTO)

- SAE B or SAE C power take off (PTO) drives. Engine power can also be taken from the front of the engine on some applications.

- General

- Caterpillar yellow paint, with optional colors available at request

- Vibration damper

- Lifiting eyes