Overview

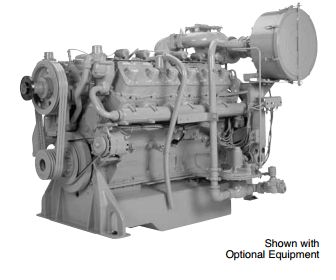

Cat® G3412 Industrial Gas Engine. Ratings: 448-475 bkW (600-637 bhp) @ 1800 rpm are NSPS site compliant capable with customer-supplied aftertreatment. Some ratings also have standard emission settings available for export only. For specific emission information, please consult your local Cat Dealer.

Specifications

| Bore | 137 mm (5.4 in) |

| Stroke | 152 mm (6.0 in) |

| Displacement | 27 L (1649³) |

Benefits & Features

Emissions

Ratings are NSPS site compliant capable with customer-supplied aftertreatment. Some ratings also have standard emission settings available for export only. For specific emission information, please refer to the engine spec sheet.

Engine Design

- Improved reliability and durability

- Ability to burn a wide spectrum of gaseous fuels

- Robust diesel strength design prolongs life and lowers owning and operating costs

- Broad operating speed range

Full Range of Attachments

Large variety of factory-installed engine attachments reduces packaging time

Specifications

| Minimum Power | — |

| Maximum Power | — |

| Frequency | 1800 rpm |

| Bore | 137 mm (5.4 in) |

| Stroke | 152 mm (6.0 in) |

| Displacement | 27 L (1649³) |

| Aspiration | Turbocharged Aftercooled (TA) |

| Engine Configuration | Engine - Continuous |

| Length | 2442 mm (96 in) |

| Height | 1960 mm (77 in) |

| Weight - Net Dry | 2141 kg (4720 lb) |

| Width | 1598 mm (63 in) |

Benefits & Features

Emissions

Ratings are NSPS site compliant capable with customer-supplied aftertreatment. Some ratings also have standard emission settings available for export only. For specific emission information, please refer to the engine spec sheet.

Engine Design

- Improved reliability and durability

- Ability to burn a wide spectrum of gaseous fuels

- Robust diesel strength design prolongs life and lowers owning and operating costs

- Broad operating speed range

Full Range of Attachments

Large variety of factory-installed engine attachments reduces packaging time

Quality

Every Cat engine is manufactured to stringent quality standards in order to assure customer satisfaction.

World-class Product Support Offered Through Global Cat Dealer Network

- Scheduled maintenance, including S•O•SSM sample

- Customer Support Agreements (CSA)

- Caterpillar Extended Service Coverage (ESC)

- Superior dealer service network

- Extended dealer service network through the CatIndustrial Service Distributor (ISD) program

Data not available.

Standard Equipment

- Air Inlet System

- Air cleaner — single element with service indicator

- Control System

- Governor — Woodward PSG mechanica

- Governor control — positive locking

- Cooling System

- Thermostats and housing

- Jacket water pump

- Aftercooler water pump

- Aftercooler core

- Exhaust System

- Watercooled exhaust manifolds

- Dry exhaust elbow

- Flywheel & Flywheel Housing

- SAE No. 0 flywheel

- SAE No. 0 flywheel housing

- SAE standard rotation

- Fuel System

- Gas pressure regulator

- Natural gas carburetor

- Ignition System

- Digital ignition system

- Instrumentation

- Service meter

- Lube System

- Crankcase breather — top mounted

- Oil cooler

- Oil filter — RH

- Auxiliary oil reservoir

- Rear sump oil pan

- Oil filler in valve cover and dipstick — RH

- Mounting System

- Engine supports

- Protection System

- Shutoff

- General

- Paint — Cat yellow

- Crankshaft vibration damper and drive pulleys

- Lifting eyes

Optional Equipment

- Air Inlet System

- Air cleaner

- Air inlet adapter

- Precleaner

- Air cleaner rain cap

- Charging System

- Battery chargers

- Charging alternators

- Ammeter gauge

- Ammeter gauge and wiring

- Control mounting

- Control System

- EG3P/2301A speed control governor

- PSG electric governor

- PSG pneumatic governor

- Cooling System

- Radiators

- Blower fan and fan drives for customer suppliedradiators

- ATAAC conversion

- Aftercooler

- Expansion tank

- Heat exchanger

- Exhaust System

- Flexible fittings

- Elbows

- Flanges

- Rain caps

- Mufflers

- Fuel System

- Dual gas regulator

- Low energy fuel carburetor

- Low pressure gas conversion

- Propane and natural gas valve and jet kits

- Fuel filter

- Ignition System

- CSA ignition

- Ignition ground wiring harness

- Power supply — digital ignition system

- Instrumentation

- Alarm module

- Gauges and instrument panels

- Lube System

- Auxiliary oil reservoir removal

- Lubricating oil

- Mounting System

- Vibration isolators

- Power Take-Offs

- Auxiliary drive pulleys

- Enclosed clutch

- Clutch support

- Front stub shaft

- Flywheel stub shaft

- Pulley removal

- Protection System

- Gas valves

- Status control box interconnect wiring harness

- Starting System

- Air starting motor

- Electric air start control

- Air pressure regulator

- Air silencer

- Electric starting motors — single 24-volt

- Starting aids

- Battery sets (24-volt dry), cables, and rack

- General

- Tool set

- Digital diagnostic tool