Overview

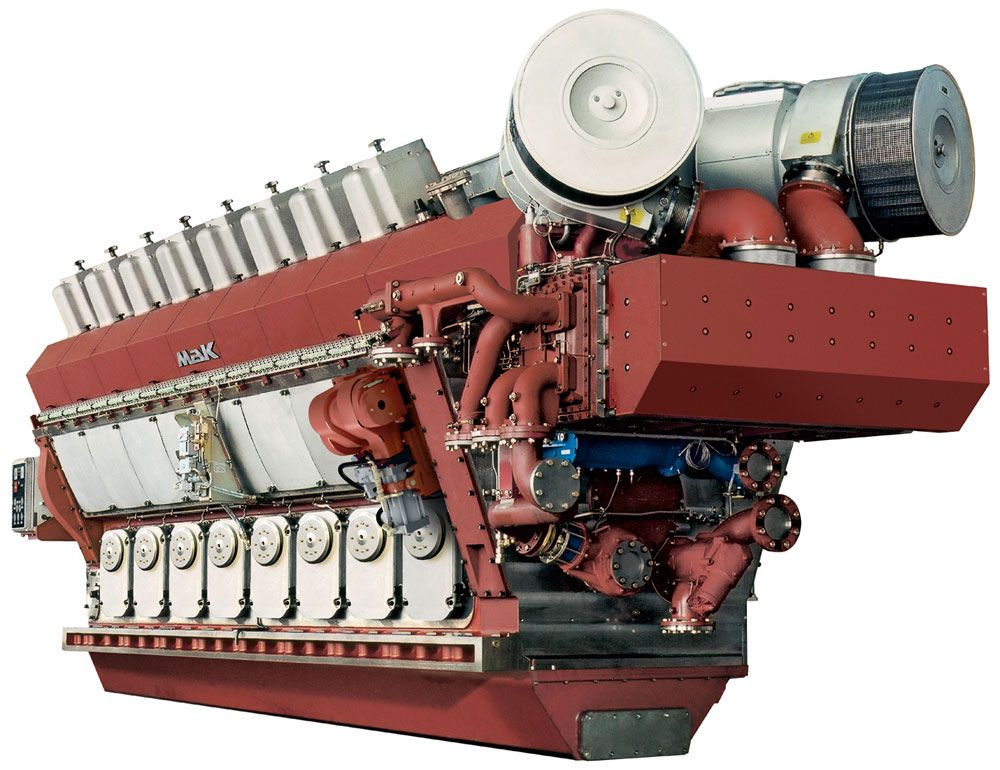

The M 32 C V-engine was introduced in 2000 in 12- and 16-cylinder versions. With a bore of 320 mm and a stroke of 460 mm, it covers a power range of 6,000 - 8,000 kW in the 720 and 750 rpm ranges. The engine is designed to meet not only the demands of the marine market but also those of the stationary electric power generation and oil & gas industry. The consistent application of the MaK long-stroke engine design and development along with the incorporation of as many in-line engine components as possible is clearly and impressively demonstrated in the external configuration - a compact, simple and clean design.

Specifications

| Power Range | 6000-8000 kW |

| Speed Range | 720-750 rpm |

| Emissions | IMO II |

Benefits & Features

A compact, simple and clean design.

Designed to comply with current and future emission regulations the VM 32 C engine combines safety and operational reliability with fuel efficiency and long maintenance- and overhaul intervals. Component groups like the cylinder head or the dry engine block with its integrated coolant-, lube oil- and air ducts follow the modular engine design concept and do guarantee operator friendly service and maintenance through easy access to parts and components. The VM 32 C can be used in main propulsion as well as auxiliary applications and is designed to operate on MDO as well as HFO.

Low Emission Engine for low NOx

By combining increased compression ratio and the Miller effect, NOx emissions can be reduced by round about 30 % without sacrificing engine efficiency.

Outstanding Economical Operation

Reliable heavy fuel oil operation, low fuel and lubricating oil consumption, together with easy maintenance and long maintenance intervals, mean outstanding economical operation.

Specifications

| Power Range | 6000-8000 kW |

| Speed Range | 720-750 rpm |

| Emissions | IMO II |

| Aspiration | Turbocharged |

| Bore | — |

| Stroke | — |

| Rotation from Flywheel End | Counterclockwise/Clockwise |

| Configuration | 12,16 Cylinder |

| Swept Volume | — |

| Minimum Dry Weight | — |

| Minimum Length | — |

| Maximum Length | — |

| Minimum Height | — |

| Maximum Height | — |

| Minimum Width | — |

| Maximum Width | — |

Benefits & Features

A compact, simple and clean design.

Designed to comply with current and future emission regulations the VM 32 C engine combines safety and operational reliability with fuel efficiency and long maintenance- and overhaul intervals. Component groups like the cylinder head or the dry engine block with its integrated coolant-, lube oil- and air ducts follow the modular engine design concept and do guarantee operator friendly service and maintenance through easy access to parts and components. The VM 32 C can be used in main propulsion as well as auxiliary applications and is designed to operate on MDO as well as HFO.

Low Emission Engine for low NOx

By combining increased compression ratio and the Miller effect, NOx emissions can be reduced by round about 30 % without sacrificing engine efficiency.

Outstanding Economical Operation

Reliable heavy fuel oil operation, low fuel and lubricating oil consumption, together with easy maintenance and long maintenance intervals, mean outstanding economical operation.

Flexible Camshaft Technology (FCT)

Building upon the emission reduction system integration concept, FCT achieves synergy between flexible fuel systems and advanced air systems with maximum utilization of the current engine design

Technically lower risk application of existing technology

Data not available.

Standard Equipment

- Air Inlet System

- Air intake silencer/filter

- Control System

- Speed governor cabinet incl. load sharing unit (for multiple engine plant only)

- Protection system (external cabinet)

- Serial link interface (MODbus/canbus)

- Start/stop panel

- Protection panel (emergency stop, override, reset push buttons)

- Cooling System

- 2-stage charge air cooler

- HT cooling water pump (engine driven)

- Electronic cooling water preheater

- Exhaust System

- Turbocharger at flywheel end

- Exhaust gas expansion joint

- Exhaust gas insulated manifolds

- Fuel System

- Fuel indicator filter

- Fuel circulating pump (electronically driven/for MDO/MGO only)

- Fuel pressure valve (separate/for MDO/MGO only)

- Instrumentation

- Local control panel

- Pressure and temperature indicator

- Control push buttons and lamps

- Emergency stop lever

- Lube System

- Lube oil pump (engine driven)

- Pressure regulating valve

- Lube oil safety filter

- Lube oil self-cleaning filter

- Lube oil plate cooler (separate)

- Dry sump

- Mounting System

- Rigid mounting

- High flexible coupling

- Starting System

- Starting air valve

- Electrical barring device

- General

- Torsional Vibration Calculation (TVC)

- Lifting device (rental)

Optional Equipment

- Air Inlet System

- Air inlet transition piece

- Expansion joint

- Silencer/filter

- Air inlet shut-off valve

- Control System

- Engine alarm system

- Remote control system

- Starter for electric driven pumps

- 24 DC UPS

- Remote indicators (start air pressure, engine speed, etc.)

- Cooling System

- HT cooling water pump (electric driven)

- LT cooling water pump (electric driven)

- Sea water cooling pump (electric driven)

- FW/SW plate cooler

- Temperature control valve

- Steam / thermal oil cooling water preheater

- Exhaust System

- Turbocharger at counter flywheel side

- Silencer (with or without spart arrester)

- Fuel System

- HFO treatment and supply modules

- HFO supply and booster pumps (electrical driven)

- HFO self-cleaning automatic filter

- Mixing tank

- HFO pressure regulating valve

- HFO final preheater

- HFO viscosity control device

- Fuel oil cooler

- Lube System

- Lube oil treatment and combined modules

- Lube oil pump (electrical driven)

- Temperature control valve

- Pre-lubricating oil pump (electrical driven)

- Wet sump with dip stick

- Lube oil centrifuge

- Mounting System

- Resilient mounting

- Flexible pipe connections

- Starting System

- Starting air receiver

- Starting air compressor

- General

- PTO shaft on counter flywheel side

- Engine PTO coupling

- Reduction gear

- Reduction gear PTO coupling

- PTO alternator

- Cat Propulsion Systems