M 25 ENon-Current

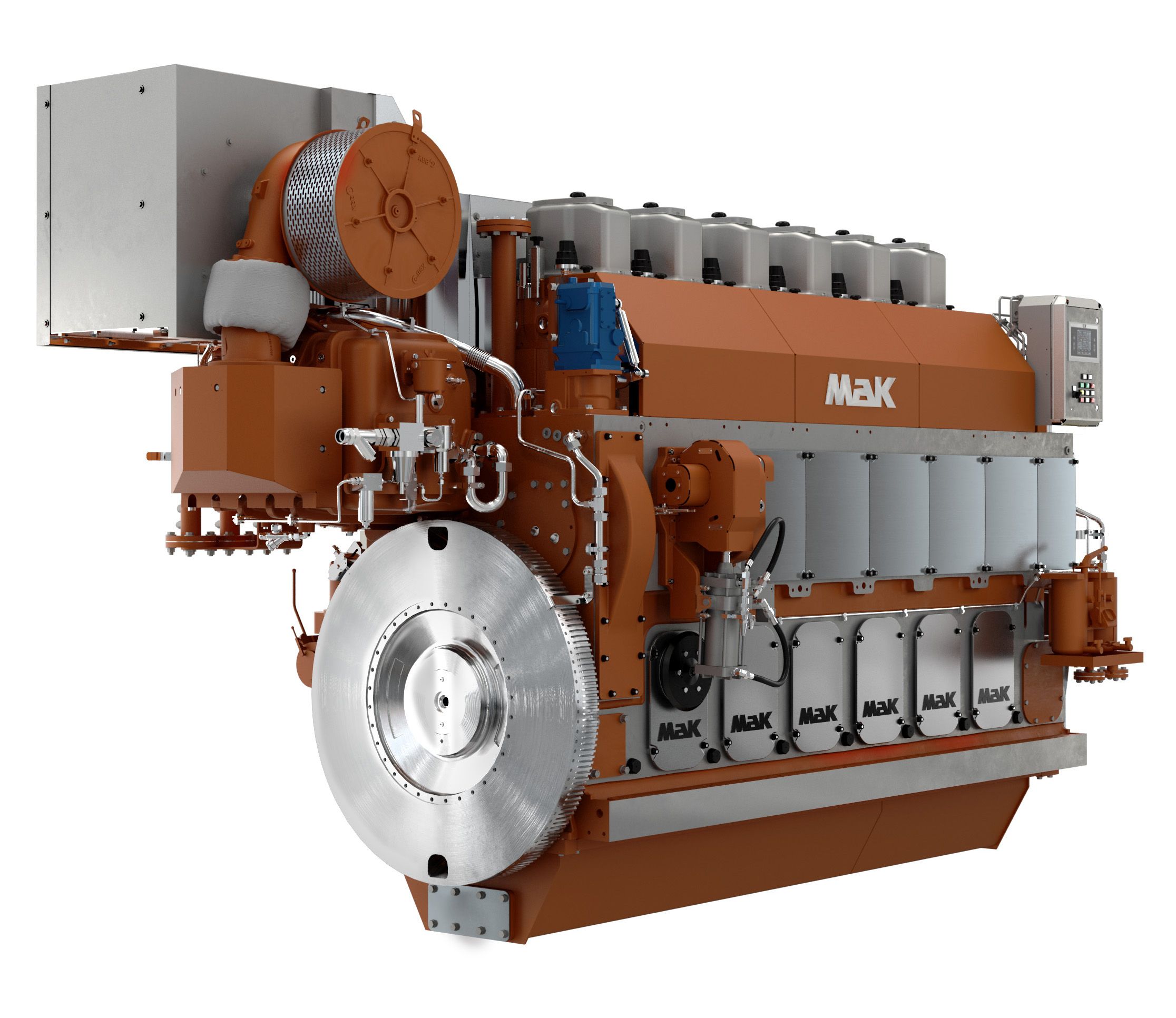

M 25 E Propulsion EngineOverview

The new M 25 E has been designed to completely meet the ultimate customer requirements, providing the lowest cost of operation while maintaining the highest uptime in the industry. Since one engine standard typically does not fit all applications, different M 25 E configurations will be available to support various application-specific requirements. Based on the proven M 25 C, all versions have been extensively optimized for best fuel consumption and load acceptance, leading reliability and durability, and efficient Selective Catalytic Reduction (SCR) operation. The service and maintenance-friendly design, remote condition monitoring and diagnostic capabilities, as well as our unmatched global product support, respond to the industry's desire to lower operational costs and down times beyond today's standards.

Specifications

| Power Range | 2100-3150 kW |

| Speed Range | 720-750 rpm |

| Emissions | IMO II / IMO III with SCR |

Benefits & Features

Emissions

For IMO III emissions the MaK M 25 E is delivered with a Scheme A factory certified SCR solution and a factory EIAPP certificate, simplifying installation and commissiong work significantly. Caterpillar's SCR technology minimizes total cost of ownership by cutting the diesel and urea expenses by offering the lowest total fluid consumption at optimized engine and SCR life time.

Performance

5% more power, Leading load response

Fuel Efficiency

A typical offshore supply vessel operator can save up to $ 250,000 per year in fuel cost.The part load efficiency of one M 25 E can save up to 40 tons of fuel per year in a variable speed application (average 60% load). Low load variable speed capability can save 50– 60 tons per year versus constant speed applications (average 20–25% load).

Specifications

| Power Range | 2100-3150 kW |

| Speed Range | 720-750 rpm |

| Emissions | IMO II / IMO III with SCR |

| Aspiration | Turbocharged |

| Bore | — |

| Stroke | — |

| Rotation from Flywheel End | Counterclockwise/Clockwise |

| Configuration | Inline 6,8,9 Cylinder |

| Swept Volume | — |

| Minimum Dry Weight | — |

| Minimum Length | — |

| Maximum Length | — |

| Minimum Height | — |

| Maximum Height | — |

| Minimum Width | — |

| Maximum Width | — |

Benefits & Features

Emissions

For IMO III emissions the MaK M 25 E is delivered with a Scheme A factory certified SCR solution and a factory EIAPP certificate, simplifying installation and commissiong work significantly. Caterpillar's SCR technology minimizes total cost of ownership by cutting the diesel and urea expenses by offering the lowest total fluid consumption at optimized engine and SCR life time.

Performance

5% more power, Leading load response

Fuel Efficiency

A typical offshore supply vessel operator can save up to $ 250,000 per year in fuel cost.The part load efficiency of one M 25 E can save up to 40 tons of fuel per year in a variable speed application (average 60% load). Low load variable speed capability can save 50– 60 tons per year versus constant speed applications (average 20–25% load).

Safety

Unmatched reliability based on the proven MaK M 25 C so you always get home safely, even in the worst conditions.

Higher Uptime equals More Revenue

Extended times between overhauls to reduce lay-days for maintenance.

Unique Solutions

Combined with propellers designed and optimized for vessels' normal cruise speed, the part load optimized M 25 E is developed for vessels where maximum engine power or propeller thrust is only required for a fraction of the operation time. Operational cost benefits are achieved by operating propellers and engines at best points of efficiency.

Onsite Product Support and Online Monitoring

The new Monitoring Alarm and Control System (MACS) from Caterpillar provides additional functionality regarding engine control, diagnostics, and remote monitoring, including the option to extend the features to engine related systems like SCR's (Selective Catalytic Reduction) where customers have elected to reduce NOx related taxes or harbor fees.

Data not available.

Standard Equipment

- Air Inlet System

- Air intake silencer / filter

- Control System

- Load sharing unit (for multiple engine plant only)

- Modular alarm control and protection system (MACS)

- Serial link interface (MODbus / canbus)

- Speed governor

- Cooling System

- Electrical cooling water preheater

- HT cooling water pump (engine driven)

- 2-stage charge air cooler

- Exhaust System

- Exhaust gas expansion joint

- Exhaust gas insulated manifolds

- Turbocharger at flywheel end

- Fuel System

- Fuel circulating pump (attached / MGO/MDO only)

- Fuel indicator filter

- Fuel pressure valve (attached / MGO/MDO only)

- Instrumentation

- Local control panel

- Pressure and temperature indicator

- Lube System

- Dry sump

- Lube oil plate cooler (separate)

- Lube oil pump (engine driven)

- Lube oil self-cleaning filter

- Pressure regulating valve

- Mounting System

- High flexible coupling

- Rigid mounting

- Starting System

- Electrical barring device

- Starting air valve

- General

- Lifting device (rental)

- Torsional Vibration Calculation (TVC)

Optional Equipment

- Air Inlet System

- Air inlet shut-off valve

- Air intake transition piece

- Expansion joint

- Silencer / filter

- Control System

- Air injection control (for better load acceptance)

- Electronic speed governor

- Engine alarm system

- Remote control system

- Remote indicators (start air pressure, engine speed, etc.)

- Starter for electric driven pumps

- 24 DC UPS

- Cooling System

- FW/SW plate cooler

- HT cooling water pump (electric driven)

- LT cooling water pump (electric driven)

- Sea water cooling pump (electric driven)

- Steam / thermal oil cooling water preheater

- Temperature control valve

- Exhaust System

- Silencer (with or without spark arrester)

- Turbocharger at counter-flywheel side

- Fuel System

- Fuel oil cooler

- HFO final preheater

- HFO pressure regulating valve

- HFO self-cleaning automatic filter

- HFO supply and booster pumps (electrical driven)

- HFO treatment and supply modules

- HFO viscosity control device

- Mixing tank

- Lube System

- Lube oil centrifuge

- Lube oil pump (electrical driven)

- Lube oil treatment and combined modules

- Pre-lubricating oil pump (electrical driven)

- Temperature control valve

- Wet sump with dip stick

- Mounting System

- Flexible pipe connections

- Resilient mounting

- Starting System

- Starting air compressor

- Starting air receiver

- General

- Cat Propulsion Systems

- Engine PTO coupling

- Part load optimzation kit for constant speed engine (SFOC improvement, smoke reduction,...)

- Part load optimization kit for variable speed engine (massive SFOC improvement,...)

- PTO alternator

- PTO shaft on counter-flywheel side

- Reduction gear

- Reduction gear PTO coupling