Overview

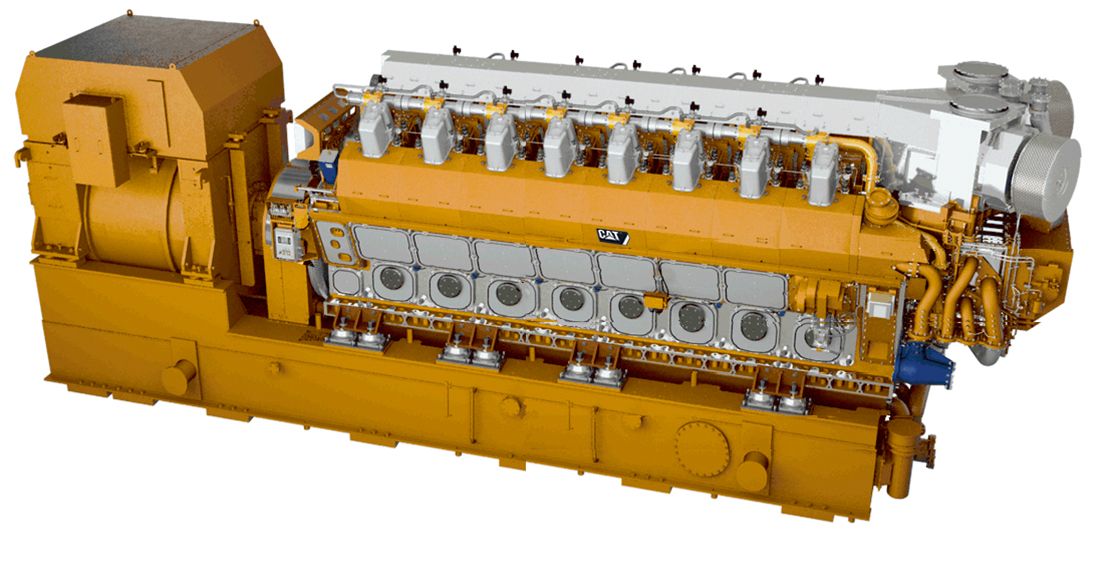

Based on the successful CM43C Cat medium speed engine, Caterpillar Motoren, Kiel designed the CM46DF to meet and exceed the CM43C reliability and lifetime expectations, while maintaining it's class leading position regarding operational efficiency and reliability. Applying the same design philosophies, the CM46DF will share the same footprint with the CM43C providing the opportunity to retrofit CM43C engines. With it's clean design, the CM46DF does allow fast and easy access to system and components, supporting the operation, service and maintenance simplicity Cat products are known for. The CM46DF generator set is designed to operate on gaseous fuel with methane numbers down to MN 50 and liquid fuels as MGO, MDO, heavy fuels and crude oil. The CM46DF is certified to IMO Tier II standards and meets proposed IMO Tier III emissions levels while operating in gas mode. Care and attentionwas paid to customers demand for a safe and reliable operation at varying engine loads and gas qualities.

Specifications

| Maximum Rating | — |

| Emissions | IMO II/III |

| Length | — |

Benefits & Features

Ease of installation

Standard modular design allows for ease of installation and reduced complexity. Low installation cost with auxiliary systems mounted on engine and cooling water system with simple plug-in connections.

Improved Serviceability

Large inspection openings for convenient access to core engine components. The core engine components are designed for reconditioning and reuse at overhaul. All products are supported by the worldwide dealer network with factory-trained technicians which means that parts and support are never out of reach. This generator set has a segmental camshaft and split connecting rod design for quick piston and camshaft removal.

Specifications

| Maximum Rating | — |

| Emissions | IMO II/III |

| Stroke | — |

| Bore | — |

| Engine Control | Electronic |

| Displacement | — |

| Aspiration | Turbocharged- Aftercooled |

| Length | — |

| Height | — |

| Weight | — |

| Width | — |

Benefits & Features

Ease of installation

Standard modular design allows for ease of installation and reduced complexity. Low installation cost with auxiliary systems mounted on engine and cooling water system with simple plug-in connections.

Improved Serviceability

Large inspection openings for convenient access to core engine components. The core engine components are designed for reconditioning and reuse at overhaul. All products are supported by the worldwide dealer network with factory-trained technicians which means that parts and support are never out of reach. This generator set has a segmental camshaft and split connecting rod design for quick piston and camshaft removal.

Data not available.

Standard Equipment

- Engine

- Motor-driven barring gear, fitted on engine

- Emergency shutdown equipment with push button for manual emergency stop

- Cylinder Head

- Fuel injector and integrated gas admission valve with easy service and maintenance access

- Cylinder pressure sensors for highest operational reliability and efficiency, replacing conventional knocking sensor technology

- Piston, rings and liners designed for operation on gas and liquid fuels

- Turbocharger

- Optimized engine efficiency in gas and diesel operation

- Blow-off valve and waste gate technology for optimized air-fuel ratio control

- Gas System

- Double-walled gas piping to support an inherently safe engine room concept

- Leakage detection

- Gas valve unit

- Segmented gas detection system on request

- Micro Pilot Fuel Injection System

- Gear driven high pressure fuel pump and filter system with easy service access

- Reliability combined with service and maintenance simplicity, through individual ignition fuel injector and “in-cylinder head” integrated ignition fuel return pipes

- Exhaust System

- Front-mounted turbocharger at free end with transition nozzle (0 degrees from the vertical and away from engine), with compressor cleaning device

- Expansion joint separate

- Separate silencer and spark arrester

- Fresh Cooling Water System

- HT pump, fitted on engine

- LT pump, separate, vertical design, electric motor driven

- HT thermostat, remote-mounted, electric controlled

- Cooling water preheating equipment, fitted on base frame

- Lubricating Oil System

- Safety filter fitted on engine

- Force pump, fitted on engine

- Pre-lubrication pump, fitted on base frame, electric motor driven

- Automatic back-flushing filter

- Duplex filter with differential pressure indication, fitted on engine

- Pressure control valve, fitted on engine

- Thermostat, remote-mounted, electric controlled

- Connections

- Set of connecting parts between flange coupling and flywheel

- Flexible flange coupling between engine and generator

- Base frame with flywheel guard and incorporating lube oil sump tank, for engine and generator

- Mounting of engine and generator on the base frame

- Set of bonded rubber rails for resilient mounting of the base frame

- Set of flexible pipe connections

- Instrumentation

- Gauge board with liquid-dampened pressure gauges for: fuel, lubricating oil, fresh water, starting air and charge air.

- On-engine thermometers for fuel, lubricating oil, fresh water and charge air

- Electric remote speed indicator

- Turbocharger and remote speed indicator

- Exhaust gas temperature indicator

- Monitoring

- Manual control on engine, including: control panel with start/stop key, speed setting device, mechanical shutdown device, changeover of control functions from engine to remote control

- Starting solenoid valve on engine, 24 V DC

- Separate electronic speed governor