Overview

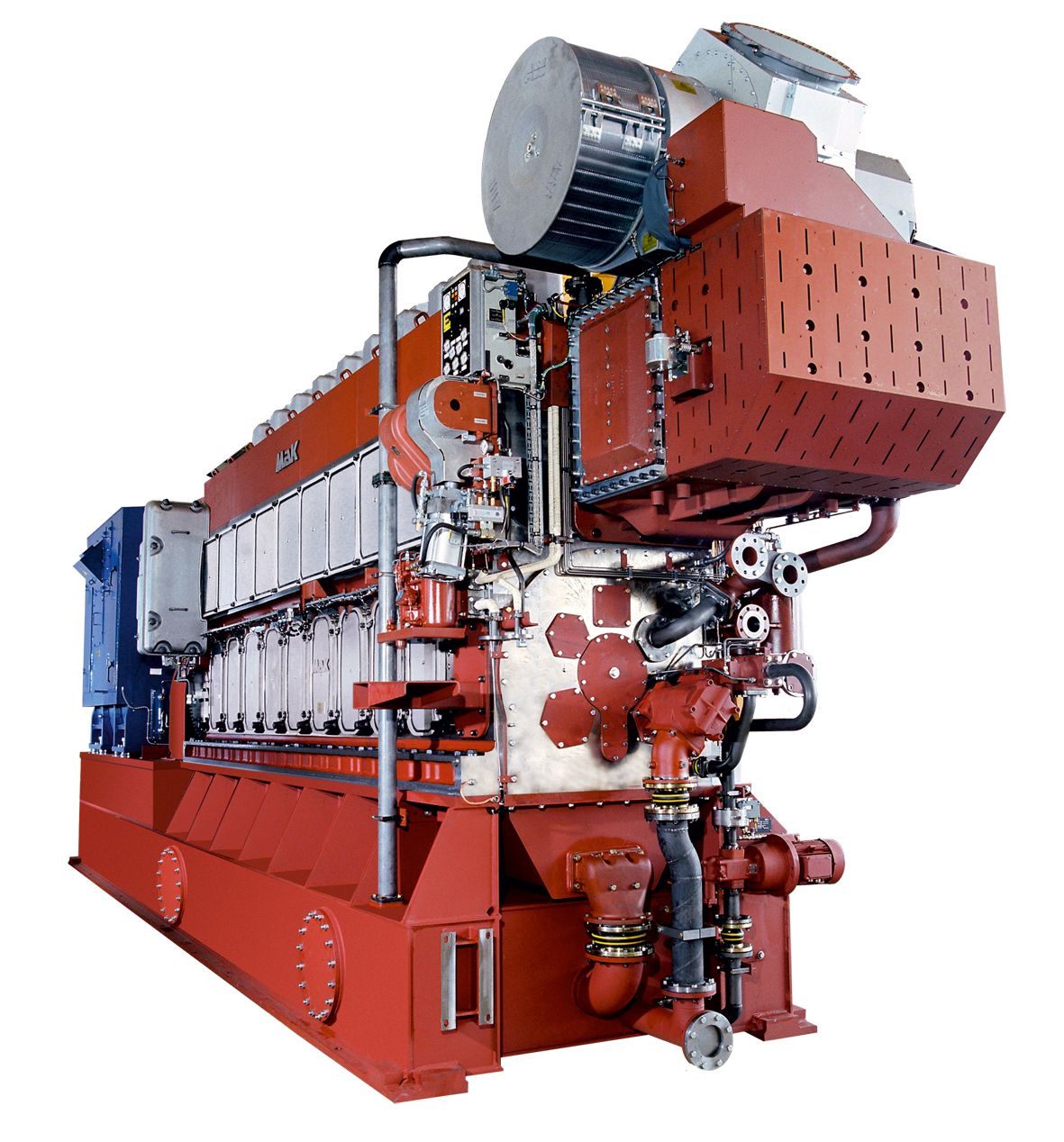

The M 32 C was introduced in 1994 in 6, 8 and 9 cylinder versions and is outstandingly suitable as a generator prime mover for electric power on ships. The robust design and moderate speed permits unlimited, continuous operation with heavy fuel oil. In-line engines – completed with generators – are mounted on a common base frame. The engine and electrics are tested prior to delivery. This ensures trouble-free installation and commissioning.

Specifications

| Minimum Rating | 2762 kWe (3456 kVA) |

| Maximum Rating | 4316 kWe (5400 kVA) |

| Configuration | 6,8,9 Cylinder |

Benefits & Features

M 32 C as a generator drive

The robust design and moderate speed permits unlimited, continuous operation with heavy fuel oil. Engine and electrics are tested prior to delivery.

Installation-friendly, due to pumps and filters installed on the engine

Nodular cast-iron engine block with integrated ducts for lubricating oil and charge air

Specifications

| Minimum Rating | 2762 kWe (3456 kVA) |

| Maximum Rating | 4316 kWe (5400 kVA) |

| Emissions/Fuel Strategy | EPA Tier 2 & IMO II |

| Configuration | 6,8,9 Cylinder |

| Bore | — |

| Stroke | — |

| Swept Volume | — |

| Weight | 73.0 t - 98.0 t (160937 lbs - 216053 lbs) |

| Width | 2600 mm - 2639 mm ( 102.4 in - 103.9 in) |

| Length | 9302 mm - 11419 mm (366.2 in - 449.6 in) |

| Height | 4801 mm - 4869 mm (189.0 in - 191,7 in) |

Benefits & Features

M 32 C as a generator drive

The robust design and moderate speed permits unlimited, continuous operation with heavy fuel oil. Engine and electrics are tested prior to delivery.

Installation-friendly, due to pumps and filters installed on the engine

Nodular cast-iron engine block with integrated ducts for lubricating oil and charge air

Emission reduction technology

Data not available.

Standard Equipment

- Air Inlet System

- Air intake silencer / filter

- Control System

- Load sharing unit (for multiple engine plant only)

- Protection system

- Serial link interface (MODbus / canbus)

- Speed governor

- Cooling System

- Electric cooling water preheater

- HT cooling water pump (engine driven)

- 2-stage charge air cooler

- Exhaust System

- Exhaust gas expansion joint

- Exhaust gas insulated manifolds

- Turbocharger at counter-flywheel side

- Fuel System

- Fuel circulating pump (attached / for MDO/MGO only)

- Fuel indicator filter

- Fuel pressure valve (attached / for MDO/MGO only)

- Instrumentation

- Control push buttons and lamps

- Emergency stop lever

- Local control panel

- Pressure and temperature indicator

- Lube System

- Engine with dry sump

- Lube oil cooler (separate)

- Lube oil pump (engine driven)

- Lube oil self-cleaning filter

- Oil sump in base frame

- Pre-lubricating oil pump (electric driven / fitted on base frame)

- Pressure regulating valve

- Mounting System

- Flexible pipe connections

- High flexible coupling

- Resilient mounting

- Starting System

- Electrical barring device

- Starting air valve

- General

- Engine, flexible coupling and generator mounted on a common base frame

- Flywheel cover

- Lifting device (rental)

- Torsional Vibration Calculation (TVC)

Optional Equipment

- Air Inlet System

- Air inlet shut-off valve

- Air intake transition piece

- Expansion joint

- Silencer / filter

- Control System

- Air injection control (for better load request)

- Electronic speed governor

- Engine alarm system

- Remote indicators (start air pressure, engine speed, etc.)

- Starter for electric driven pumps

- 24 DC UPS

- Cooling System

- CW piping for generator cooling on base frame

- CW piping for lube oil cooler on base frame

- FW/SW plate cooler

- HT cooling water pump (electric driven)

- LT cooling water pump (electric driven)

- Sea water cooling pump (electric driven)

- Temperature control valve

- Exhaust System

- Silencer (with or without spark arrester)

- Fuel System

- Fuel oil cooler

- HFO final preheater

- HFO pressure regulating valve

- HFO self-cleaning automatic filter

- HFO supply and booster pumps (electrical driven)

- HFO treatment and supply modules

- HFO viscosity control device

- Mixing tank

- Lube System

- Lube oil centrifuge

- Lube oil cooler fitted on base frame

- Lube oil pump (electrical driven)

- Lube oil treatment and combined modules

- Temperature control valve

- Mounting System

- Double resilient mounting (engine and base frame)

- Engine resiliently mounted on base frame, base frame mounted rigidly

- Flexible pipe connections

- Starting System

- Starting air compressor

- Starting air receiver

- General

- Engine PTO coupling

- Generator customer supply

- PTO shaft on counter-flywheel side