Overview

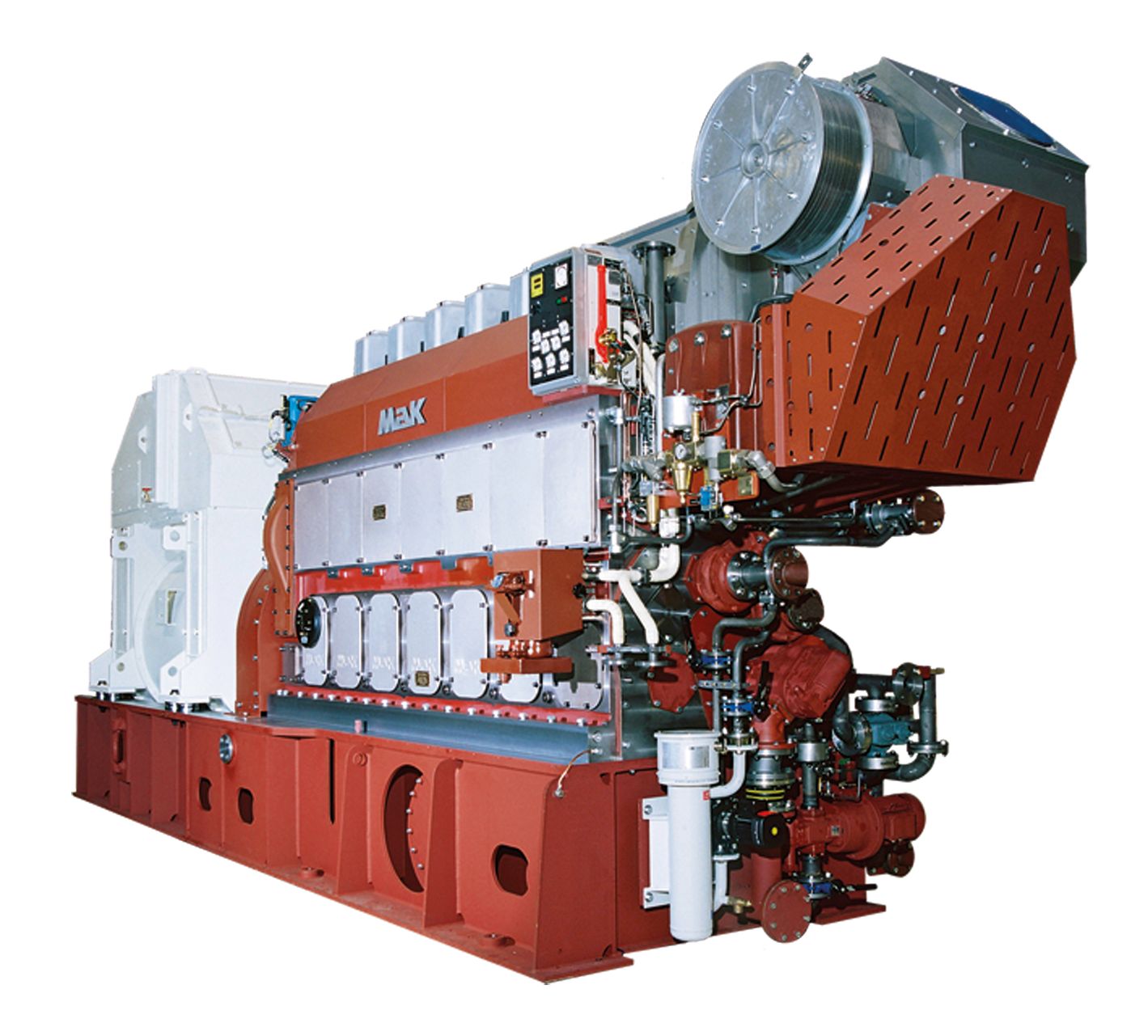

The complete diesel generator set is notable for its ease of installation, reliable operation, ease of maintenance and good component accessibility. The basis is formed by the rigid base frame as a foundation of the engine and alternator with an integrated oil sump, large oil volume and universal equipment for both HFO and MDO operation. The M 25 C has a wide range of application providing power for the continuous generation of electricity where a high level of reliability is important. The power range of the M 25 C engine series as a generator unit varies from 2,140 to 3,560 kVA.

Specifications

| Minimum Rating | 1669 kWe (2088 kVA) |

| Maximum Rating | 2877 kWe (3600 kVA) |

| Configuration | 6,8,9 Cylinder |

Benefits & Features

Intelligent simplicity

This MaK design principles is most clearly reflected in the reduction in the number of components. About 40 % of parts have been dispended. It has resulted in a marked gain in operational reliability and a reduction in operating costs.

Reliable energy supply

The complete diesel engine is notable for its ease of installation, reliable operation, ease of maintenance and good component accessibility.

Ready for installation

In addition to many outstanding technical features, the long-stroke M 25 C engine is also easy to install and provides good maintenance access to all components.

Specifications

| Minimum Rating | 1669 kWe (2088 kVA) |

| Maximum Rating | 2877 kWe (3600 kVA) |

| Emissions/Fuel Strategy | IMO II |

| Configuration | 6,8,9 Cylinder |

| Bore | — |

| Stroke | — |

| Swept Volume | — |

| Width | 2479 mm - 2534 mm ( 97.6 in - 99.8 in) |

| Length | 8070 mm - 9516 mm (317.7 in - 374.6 in) |

| Height | 3911 mm - 3963 mm (154.0 in - 156.0 in) |

| Weight | 43 t - 56 t (94799 lbs - 123459 lbs) |

Benefits & Features

Intelligent simplicity

This MaK design principles is most clearly reflected in the reduction in the number of components. About 40 % of parts have been dispended. It has resulted in a marked gain in operational reliability and a reduction in operating costs.

Reliable energy supply

The complete diesel engine is notable for its ease of installation, reliable operation, ease of maintenance and good component accessibility.

Ready for installation

In addition to many outstanding technical features, the long-stroke M 25 C engine is also easy to install and provides good maintenance access to all components.

Complete propulsion system

The supply of complete propulsion systems is a market requirement which is becoming increasingly important.

System responsibility and supply from a single source, accurately matched interfaces and coordinated delivery data control

Data not available.

Standard Equipment

- Air Inlet System

- Air intake silencer / filter

- Control System

- Load sharing unit (for multiple engine plant only)

- Protection system

- Serial link interface (MODbus / canbus)

- Speed governor

- Cooling System

- Electric cooling water preheater

- HT cooling water pump (engine driven)

- 2-stage charge air cooler

- Exhaust System

- Exhaust gas expansion joint

- Exhaust gas insulated manifolds

- Turbocharger at counter-flywheel end

- Fuel System

- Fuel circulating pump (attached / for MDO/MGO only)

- Fuel indicator filter

- Fuel pressure valve (fitted / for MDO/MGO only)

- Instrumentation

- Control push buttons and lamps

- Emergency stop lever

- Local control panel

- Pressure and temperature indicator

- Lube System

- Lube oil cooler (separate)

- Lube oil pump (engine driven)

- Lube oil self-cleaning filter

- Pre-lubricating pump (electric driven / fitted on base frame)

- Oil sump in base frame

- Pressure regulating valve

- Mounting System

- Flexible pipe connections

- High flexible coupling

- Resilient mounting on base frame

- Starting System

- Electrical barring device

- Starting air valve

- General

- Engine, flex. coupling and generator mounted on a common base frame

- Flywheel cover

- Lifting device (rental)

- Torsional Vibration Calculation (TVC)

Optional Equipment

- Air Inlet System

- Air inlet shut-off valve

- Air intake transition piece

- Expansion joint

- Silencer / filter

- Control System

- Air injection control (for better load request)

- Electronic speed governor

- Engine alarm system

- Remote indicators (start air pressure, engine speed, etc.)

- Starter for electric driven pumps

- 24 DC UPS

- Cooling System

- CW piping for generator cooliing on base frame

- CW piping for lubricating oil cooler on base frame

- FW/SW plate cooler

- HT cooling water pump (electric driven)

- HT temperature control valve fitted on base frame

- LT cooling water pump (electric driven)

- Sea water cooling pump (electric driven)

- Temperature control valve

- Exhaust System

- Silencer (with or without spark arrester)

- Fuel System

- Fuel oil cooler

- HFO final preheater

- HFO pressure regulating valve

- HFO self-cleaning automatic filter

- HFO supply and booster pumps (electric driven)

- HFO treatment and supply modules

- HFO viscosity control device

- Mixing tank

- Lube System

- Lube oil centrifuge

- Lube oil cooler fitted on base frame

- Lube oil pump (electrical driven)

- Lube oil treatment and combined modules

- Temperature control valve fitted on base frame

- Mounting System

- Double resilient mounting (engine and base frame)

- Starting System

- Starting air compressor

- Starting air receiver

- General

- Engine PTO coupling

- Generator customer supply

- PTO shaft on counter-flywheel side