Overview

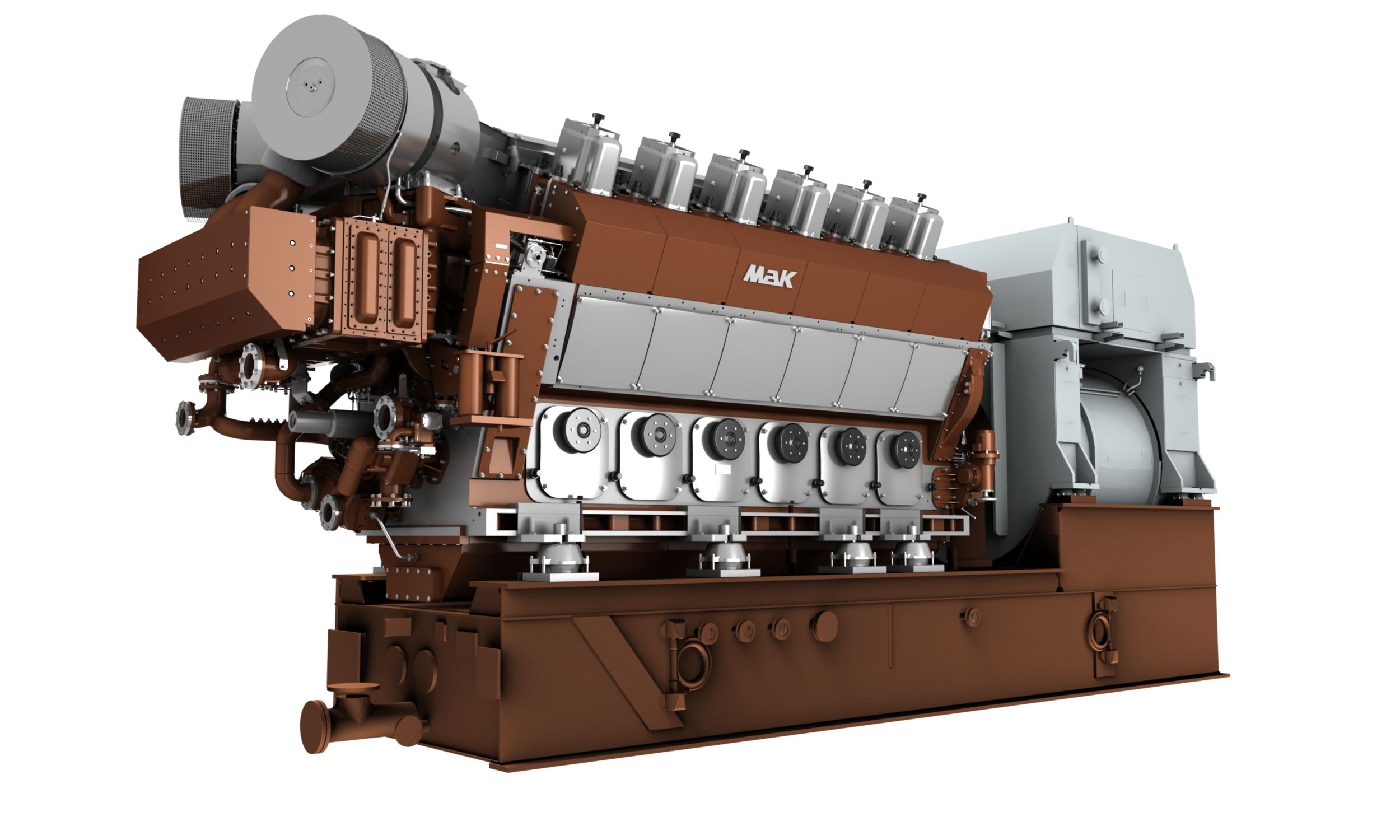

The VM 32 E is available as a generator set with a new “flexibly-mounted engine on base frame” design and a wet oil sump solution with a resilient mounting for generator set applications without base frame. In this design, the engine is resiliently mounted on the base frame with conical mounts. The base frame itself is reduced in weight and height to make transport and handling during the installation phase easier. Last but not least, the ship's weight and design will benefit from the lower weight and the smaller dimensions for its entire lifetime, especially on smaller ship applications. The generator is mounted on non-resilient adjustable spacers, which is the most economical way to establish a perfect mounting plane and allows an easy realignment of the generator. As the wet oil sump, the reduced vibration levels will help the crew sleep well during their off shift while the engine is running.

Specifications

| Minimum Rating | 6099 kWe (7632 kVA) |

| Maximum Rating | 8593 kWe (10752 kVA) |

| Configuration | 12,16 Cylinder |

Benefits & Features

Ease of installation

Part load optimization kit (PLK) for constant speed available.

Flexible Camshaft Technology (FCT) allows lower SFOC at part load area.

Specifications

| Minimum Rating | 6099 kWe (7632 kVA) |

| Maximum Rating | 8593 kWe (10752 kVA) |

| Emissions/Fuel Strategy | IMO II |

| Configuration | 12,16 Cylinder |

| Bore | — |

| Stroke | — |

| Swept Volume | — |

| Length | 10703 mm - 12149 mm (421.4 in - 478.3 in) |

| Width | 3526 mm (138.8 in) |

| Weight | 120.0 t - 140.0 t (264554 lbs - 308647 lbs) |

| Height | 4639 mm (182.6 in) |

Benefits & Features

Ease of installation

Part load optimization kit (PLK) for constant speed available.

Flexible Camshaft Technology (FCT) allows lower SFOC at part load area.

Technically lower risk – application of existing technology

Data not available.

Standard Equipment

- Air Inlet System

- Air intake silencer / filter

- Control System

- Protection system (external cabinet)

- Serial link interface (MODbus / canbus)

- Speed governor

- Cooling System

- Electric cooling water preheater

- HT cooling water pump (engine driven)

- 2-stage charge air cooler

- Exhaust System

- Exhaust gas expansion joint

- Exhaust gas insulated manifolds

- Turbocharger at counter-flywheel end

- Fuel System

- Fuel circulating pump (electric driven / for MDO/MGO only)

- Fuel indicator filter

- Fuel pressure valve (separate / for MDO/MGO only)

- Instrumentation

- Control push buttons and lamps

- Emergency stop lever

- Local control panel

- Pressure and temperature indicator

- Lube System

- Engine with dry sump

- Lube oil plate cooler (separate)

- Lube oil pump (engine driven)

- Lube oil safety filter

- Lube oil self-cleaning filter (separate)

- Oil sump in base frame

- Pre-lubricating oil pump (electr. Driven/fitted on base frame)

- Pressure regulating valve

- Mounting System

- Engine resiliently mounted on base frame, base frame mounted rigidly

- Flexible pipe connections

- High flexible coupling

- Starting System

- Electrical barring device

- Starting air valve

- General

- Engine, flexible coupling and generator mounted on a common base frame

- Flywheel cover

- Lifting device (rental)

- Torsional Vibration Calculation (TVC)

Optional Equipment

- Air Inlet System

- Air inlet shut-off valve

- Air intake transition piece

- Expansion joint

- Silencer / filter

- Control System

- Electronic speed governor

- Engine alarm system

- Remote indicators (start air pressure, engine speed, etc.)

- Starter for electric driven pumps

- 24 DC UPS

- Cooling System

- CW piping for generator cooling on base frame

- CW piping for lubricating oil cooler on base frame

- FW/SW plate cooler

- HT cooling water pump (electric driven)

- LT cooling water pump (electric driven)

- Sea water cooling pump (electric driven)

- Temperature control valve

- Exhaust System

- Silencer (with or without spark arrester)

- Fuel System

- Fuel oil cooler

- HFO final preheater

- HFO pressure regulating valve

- HFO self-cleaning automatic filter

- HFO supply and booster pumps (electrical driven)

- HFO treatment and supply modules

- HFO viscosity control device

- Mixing tank

- Lube System

- Lube oil centrifuge

- Lube oil pump (electrical driven)

- Lube oil treatment and combined modules

- Temperature control valve

- Mounting System

- Resilient mounting on base frame

- Starting System

- Starting air compressor

- Starting air receiver

- General

- Generator customer supply