Overview

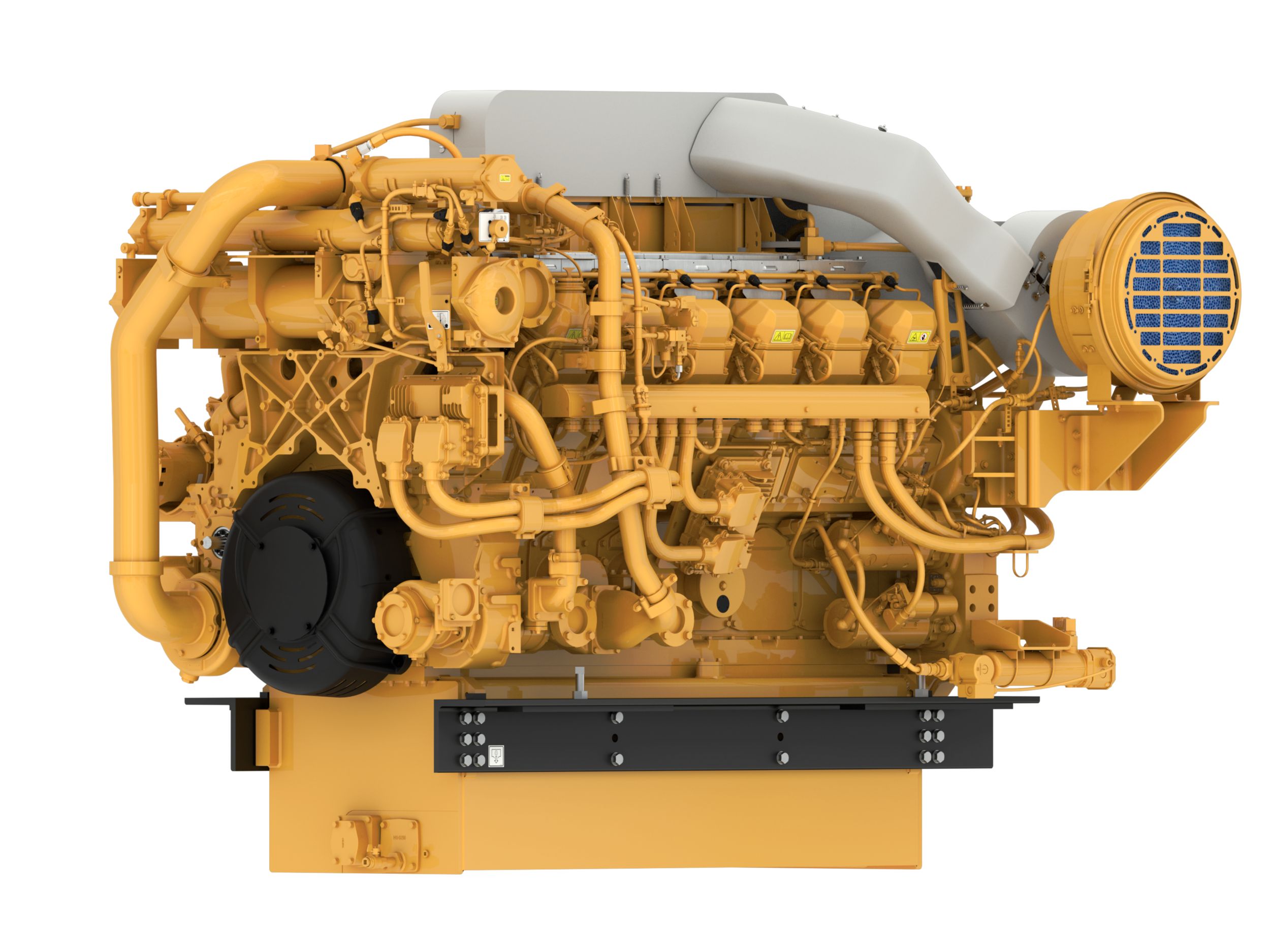

The Cat® 3512C marine propulsion engine delivers results under hard working conditions. This engine family is designed to maximize the performance of your invested dollars with a wide range of available power ratings, standard and reverse rotation configurations, no required aftertreatment, and efficient fuel consumption. This engine is available as IMO II or China Stage II emissions compliant making it an excellent propulsion engine choice for Tug, Governmental, and other workboat applications.

Specifications

| Power Range | 1281 - 2552 bhp |

| Speed Range | 1200 - 1800 rpm |

| Emissions | IMO II, China Stage II |

Benefits & Features

Driving down total cost of ownership

A wide range of power ratings available, No aftertreatment technology required, Fuel consumption nominal rated BSFC

COMMITTED TO SUSTAINABLE DEVELOPMENT

Modified piston bowl shape to improve combustion and reduce emissions. Better electronic injection control using crank timing vs. cam timing, IMO Tier II Emissions Compliant, Lower IMAT = Lower NOx

IMPROVING WORKFORCE EFFICIENCY

Electronic governing (A6 ECU), Instrument panel shipped loose with color Marine Power Display (MPD), cold mode start strategy, programmable low idle, optional marine alarm and protection system

Specifications

| Power Range | 1281 - 2552 bhp |

| Speed Range | 1200 - 1800 rpm |

| Emissions | IMO II, China Stage II |

| Aspiration | Twin Turbocharged Aspirator |

| Bore | — |

| Stroke | — |

| Stroke - HD | — |

| Displacement | — |

| Displacement - HD | — |

| Rotation from Flywheel End | Counterclockwise or Clockwise |

| Configuration | V 12, 4-Stroke-Cycle Diesel |

| Maximum Length | — |

| Maximum Width | — |

| Minimum Dry Weight | — |

| Minimum Width | — |

| Minimum Height | — |

| Minimum Length | — |

| Maximum Height | — |

| Maximum Dry Weight | — |

| Length - Engine | — |

Benefits & Features

Driving down total cost of ownership

A wide range of power ratings available, No aftertreatment technology required, Fuel consumption nominal rated BSFC

COMMITTED TO SUSTAINABLE DEVELOPMENT

Modified piston bowl shape to improve combustion and reduce emissions. Better electronic injection control using crank timing vs. cam timing, IMO Tier II Emissions Compliant, Lower IMAT = Lower NOx

IMPROVING WORKFORCE EFFICIENCY

Electronic governing (A6 ECU), Instrument panel shipped loose with color Marine Power Display (MPD), cold mode start strategy, programmable low idle, optional marine alarm and protection system

FULLY INTEGRATED MARINE POWER SOLUTION

Single-source support, Caterpillar warranty for all factory packaged components, Industry-leading one-year warranty on parts

Data not available.

Standard Equipment

- Air Inlet System

- Separate circuit aftercooler core, corrosion resistant coated (air side)

- Powercore air cleaner

- Control System

- Dual Caterpillar A6 Electronic Engine Control with Electronic Unit Injector Fuel System

- Rigid Wiring Harness (20 amp DC power required to drive Electronic Engine Control Module)

- Exhaust System

- 3500C engines:

- Fuel System

- Fuel transfer pump

- Electronically Controlled Unit Injectors

- Duplex Fuel Filters

- Instrumentation

- Electronic service meter, instrument panel (24V), start/stop switch, emergency stop button, maintenance due light, diagnostic light, warning light, maintenance clear switch, start motor magnetic switch, 15 and 3A breakers

- Graphical Unit (Color Marine Power Display) for analog or digital of:

- Lube System

- Crankcase breather groups, Top mounted

- Oil filler and dipstick, LH or RH

- Oil pump, gear type

- 250 / 500 / 1000 hour sump oil pan options

- Mounting System

- Rails, engine mounting, ledge type, 203 mm x 203 mm (8 in x 8 in) or Front Trunnion

- Power Takeoffs

- Accessory drives: Lower RH, lower LH

- Front housing, two-sided

- Protection System

- A6 Electronic Monitoring System provides customer programmable engine derating strategies to protect against adverse operating conditions

- Emergency stop push button (located in Electronic Instrument Panel)

- Safety shutoff protection:

- General

- Vibration damper and guard

- Lifting eyes

- NOTE: Engines for heat exchanger cooling do NOT include heat exchange

- Flywheel and Flywheel Housing

- Flywheel, SAE No. 00, 183 teeth

- Flywheel housing, SAE No. 00, 183 teeth

- Cooling System

- Oil cooler

- Thermostats and housing, Full open temperature 92 C (198 F)

- Jacket water pump, gear driven, centrifugal

- Auxiliary fresh water pump

- Aftercooler system: If using glycol, up to maximum 20% glycol concentration is allowed

Optional Equipment

- Air Inlet System

- Air Inlet Adapters

- Charging System

- Battery Chargers

- Charging Alternator 24V/60amp

- Control System

- Throttle Control

- Cooling System

- Coolant Shunt Tank

- Cooling System Options

- Exhaust System

- Flexible Fittings

- Elbows, Flexible Fittings, and Flanges for exhaust connections

- Flanges

- Flange and Exhaust Expanders

- Mufflers

- Fuel System

- Fuel Cooler Heat Exchanger - Sea Water

- Primary Fuel Filter

- Fuel Level Switch

- Rigid Fuel Lines

- Flexible Fuel Lines

- Instrumentation

- Communication Modules

- Color Marine Power Display System equipped with access to Marine Digital Services

- Pilot House Instrument Panels

- Marine Gear Sensors

- Lube System

- Sump Pumps

- Lubricating Oil

- Power Take-Offs

- Stub Shafts

- Crankshaft Pulleys

- Damper Guard

- Flexible Coupling and Guards

- Marine Society Requirements

- Green Passport Documentation

- Spray Shielding

- Protection System

- Shutoff and Alarm Contactors

- Special Appearance Packages

- Special Appearance Packages with Chrome Covers

- Yacht Class Finish

- Starting System

- Air Starting Motor Options

- Battery Sets - 24 Volt - Dry

- Battery Rack

- Mounting System

- Engine Supports

- Vibration Isolation Mountings

- Packing

- Shrink Wrap Protection

- Storage Preservation with Glycol Solution/Vapor Corrosion Inhibitor

- Export Boxing

- Export Packaging