Overview

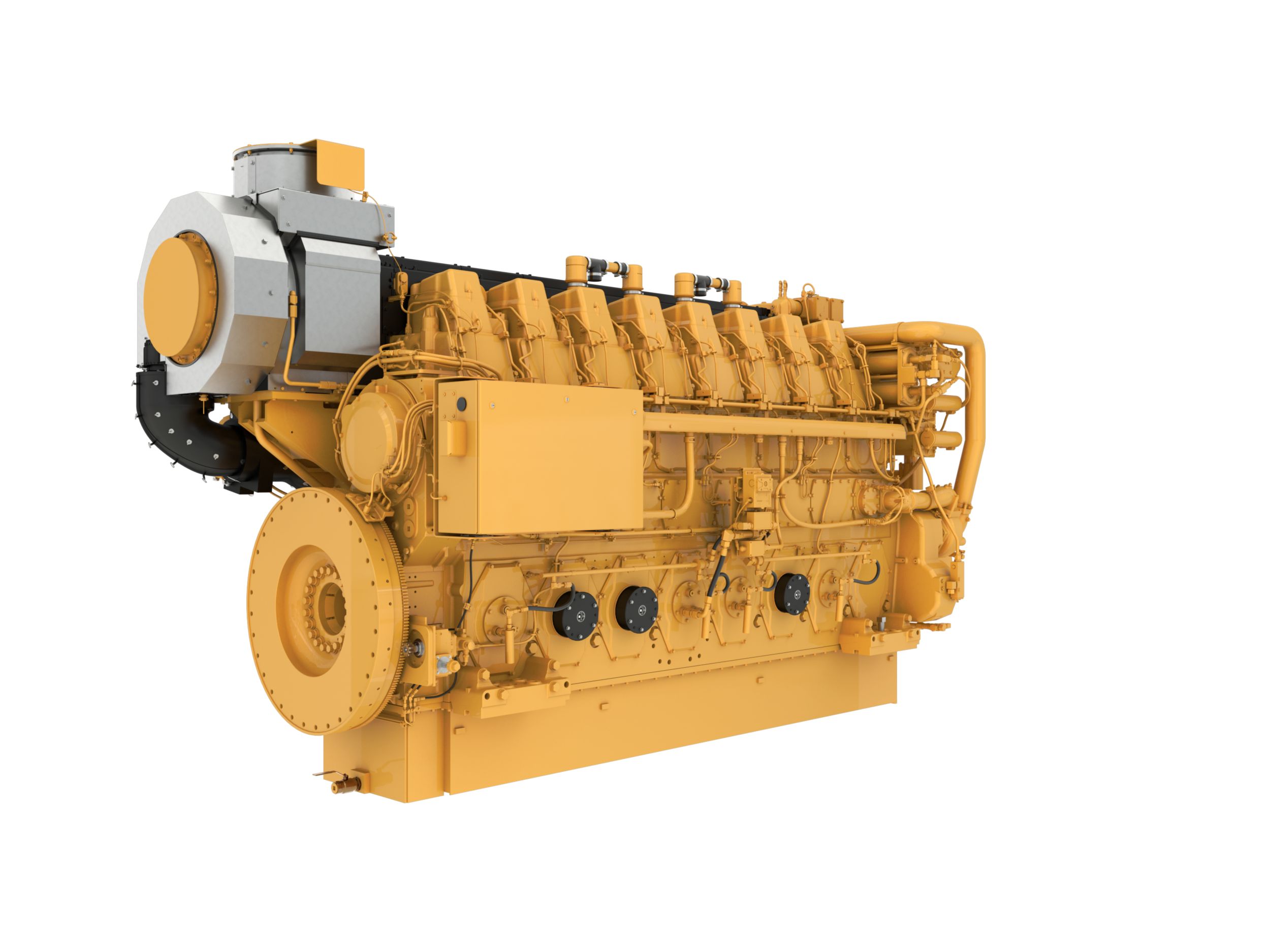

Building on the durability and reliability of the C280 engine platform, Caterpillar is pleased to offer the EPA Tier 2 compliant C280 engine line. The core components are the same as the existing C280, including the latest in EUI fuel system capabilities and state-of-the-art ADEM™ A3 Electronic Control Unit (ECU) features. Caterpillar® products continue to deliver more available power while delivering outstanding fuel efficiency. You can also count on long maintenance intervals and worldwide Caterpillar parts and service availability.

Specifications

| Power Range | 3084-4023 bhp (2300-3000 bkW) |

| Speed Range | 900 - 1000 rpm |

| Emissions | IMO II, IMO III/EPA Tier 4 |

Benefits & Features

A3 ECU

• CAN J1939 data link • Waterproof connectors • Maintenance-free • Backup ECU for redundant governing

Electronic Advantages:

• Load feedback • Programmable droop • Adjustable gain • Adjustable fuel/air ratio control • Histograms of engine operation • Cat Messenger display presents diagnostics and other engine parameters

Data Advantages through J1939 Link:

• Engine speed • Boost pressure • Throttle position • Fuel consumption rate • Inlet manifold temperature • Diagnostic codes and events • Configuration • Desired engine speed • Battery voltage • Engine load • Lifetime totals — engine hours, fuel burned, idle fuel, idle hours • Trip totals — average fuel rate, idle fuel, idle hours, engine hours, fuel burned, trip reset

Specifications

| Power Range | 3084-4023 bhp (2300-3000 bkW) |

| Speed Range | 900 - 1000 rpm |

| Emissions | IMO II, IMO III/EPA Tier 4 |

| Aspiration | TA |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Rotation from Flywheel End | Counterclockwise or clockwise |

| Configuration | In-line 8, 4-Stroke-Cycle Diesel |

| Height | — |

| Dry Weight | — |

| Width | — |

| Length | — |

Benefits & Features

A3 ECU

• CAN J1939 data link • Waterproof connectors • Maintenance-free • Backup ECU for redundant governing

Electronic Advantages:

• Load feedback • Programmable droop • Adjustable gain • Adjustable fuel/air ratio control • Histograms of engine operation • Cat Messenger display presents diagnostics and other engine parameters

Data Advantages through J1939 Link:

• Engine speed • Boost pressure • Throttle position • Fuel consumption rate • Inlet manifold temperature • Diagnostic codes and events • Configuration • Desired engine speed • Battery voltage • Engine load • Lifetime totals — engine hours, fuel burned, idle fuel, idle hours • Trip totals — average fuel rate, idle fuel, idle hours, engine hours, fuel burned, trip reset

Customer Interface Panel

• Interfaces with standard Cat® Marine Monitoring System (PLC in Price List) • Provides visual indication of ECU functionality • Accepts 4 — 20 mA or PWM remote throttle speed input • Marine alarm and protection

Electronic Unit Injectors

• “Drop-in” installation • No threaded fuel connections • High pressure inside injector only • Does not require double wall fuel lines or leak collection device • Injector synchronization not required

Data not available.

Standard Equipment

- General

- LH and RH service availability

- Air Inlet System

- Aftercooler, fresh water, corrosion resistant coated (air side)

- Crankcase breathers, top mounted

- Single turbocharger, rear-mounted, engine oil lubricated

- Air inlet adapter - Straight / 90 degree / 35 degree

- Control System

- Dual Caterpillar ADEM A4 Electronic Engine Control Modules

- Rigid Wiring Harness

- Aftercooler/oil cooler and jacket water pumps (gear driven)

- Cooling System

- Engine coolant water drains

- Single Circuit / Separate Circuit Aftercooler

- Exhaurt System

- Dry, gas tight, exhaust manifold

- Exhaust System

- Turbo speed sensors - overspeed protection

- Fuel System

- Fuel transfer pump, gear driven

- Duplex Fuel filters

- Electronically Controlled Unit Injectors

- Instrumentation

- CAT Alarm & Protection System

- Lube System

- Oil pump, gear driven

- Lube Systems

- 2 element oil cooler, engine mounted

- Duplex centrifugal oil filter - engine mounted

- Prelube pump - air / electric

- Protection System

- Crankcase explosion relief valves

Optional Equipment

- Exhaust System

- Exhaust manifold shielding - soft

- Cooling System

- Jacket Water Heaters

- Fuel System

- SOLAS shielding

- Lube System

- Front and rear oil pan drains

- Wet sump

- SOLAS shielding

- Protection System

- Oil mist detector

- Cylinder pressure relief valves

- Cylinder pressure relief valves